INTAKE MANIFOLD

DESCRIPTION

The two piece intake manifold is made of a com-

posite material. The intake manifold features a com-

pact, low rumble design that maximizes engine

performance while minimizing induction noise. A

manifold tuning valve (MTV) is used on some models.

OPERATION

The intake air plenum chambers absorb air pulsa-

tions created during each cylinder’s intake stroke.

The manifold tuning valve (if equipped) connects

both sides of the intake manifold plenums at specific

engine speeds to maximize low RPM torque, without

reducing high RPM power.

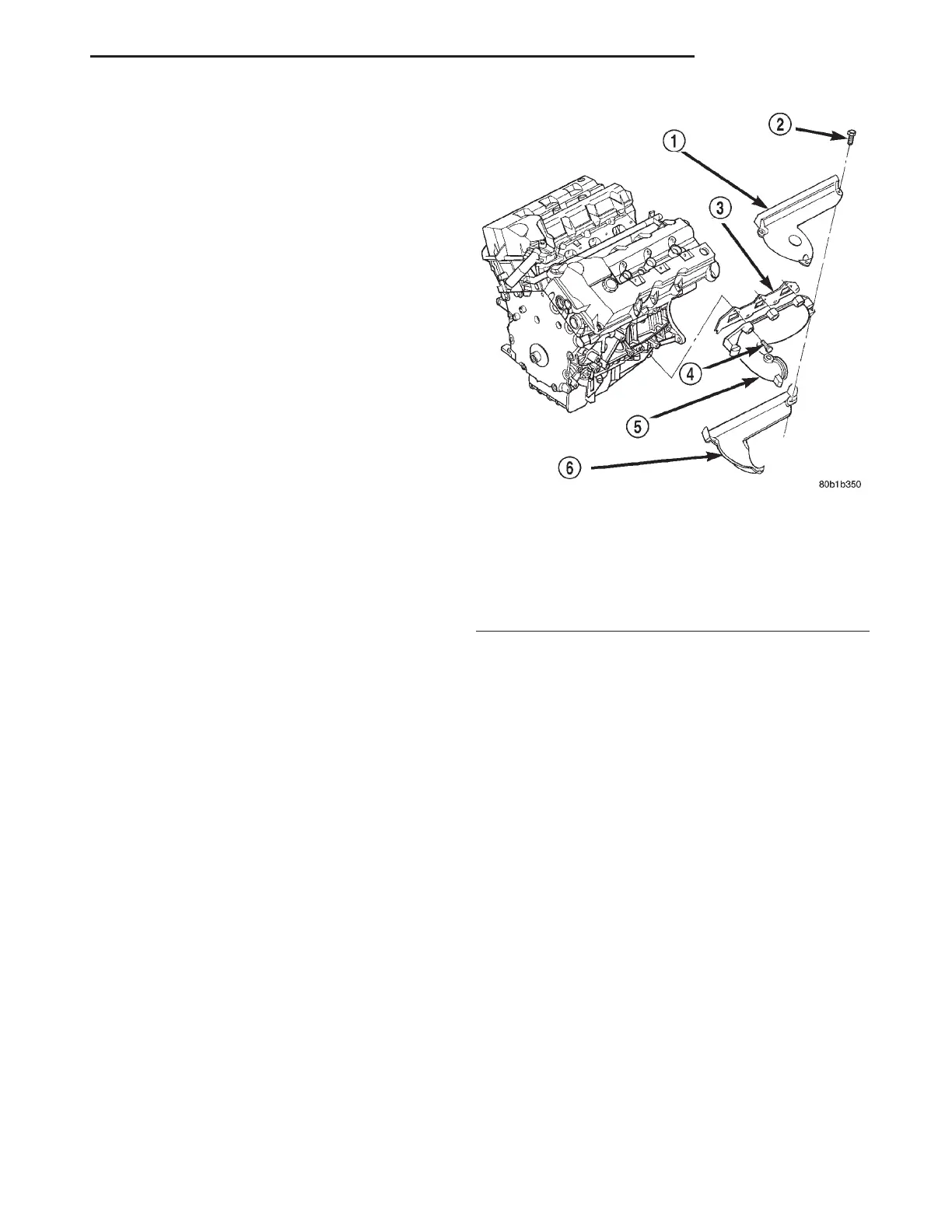

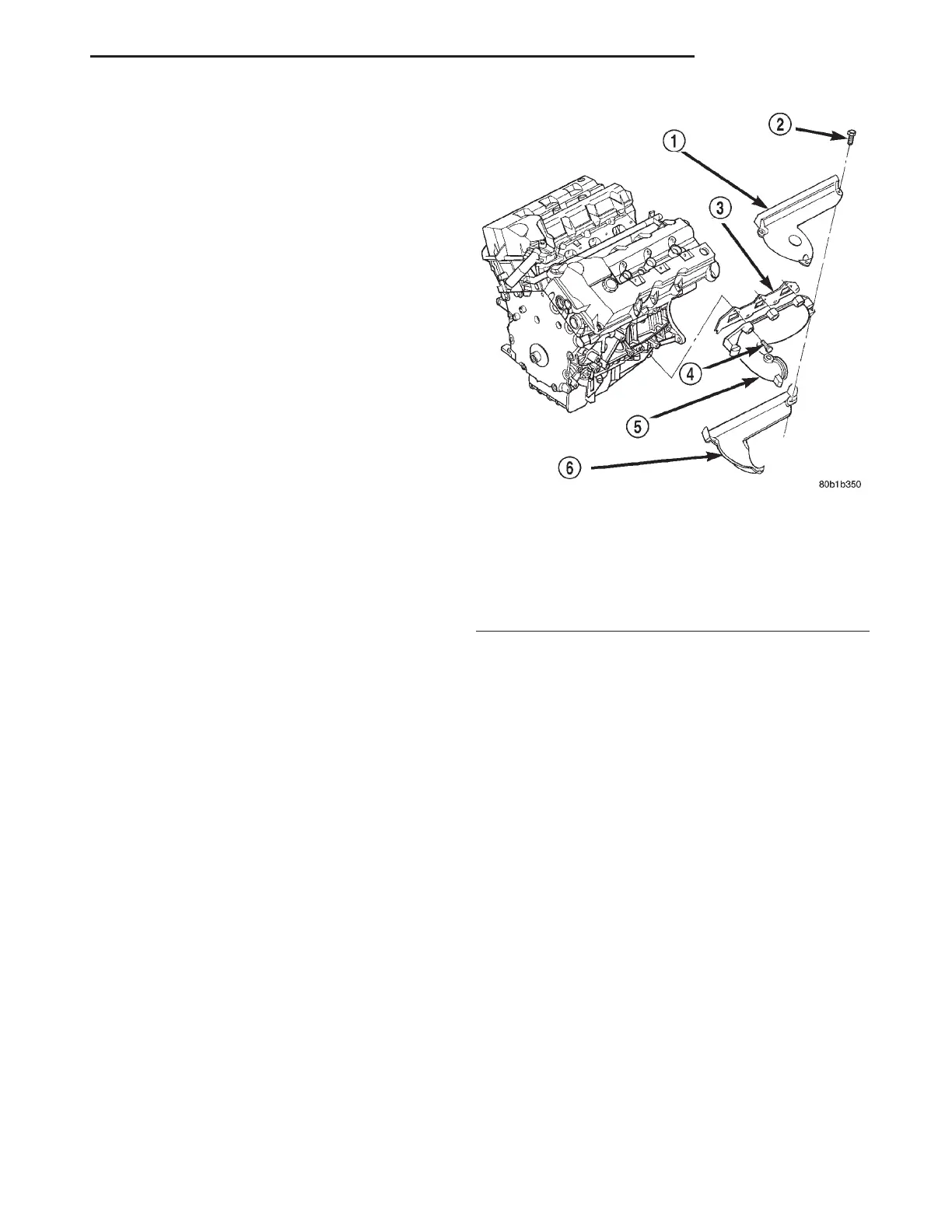

EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are a log style design and

made of cast nodular iron (Fig. 10). The outlets are

designed for V-band clamp attachment of close cou-

pled catalytic converters.

ENGINE LUBRICATION

DESCRIPTION

The lubrication system is a full-flow filtration,

pressure feed type. The oil pump body is mounted to

the engine block. The pump inner rotor is driven by

the crankshaft. A structural windage tray is used to

increase power by minimizing oil windage at high

engine RPM. An engine oil cooler is used on some

models.

OPERATION

Oil from the oil pan is pumped by an geroter type

oil pump directly coupled to the crankshaft (Fig. 11).

Oil pressure is controlled by a relief valve mounted

inside the oil pump housing. See (Fig. 11), (Fig. 12),

and (Fig. 13) for engine oil lubrication circuits.

Fig. 10 Exhaust Manifold

1 – HEAT SHIELD

2 – BOLT

3 – GASKET

4 – BOLT

5 – EXHAUST MANIFOLD

6 – HEAT SHIELD

LH 2.7L ENGINE 9 - 9

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...