CRANKSHAFT END PLAY—CHECKING

(1) Mount a dial indicator to a stationary point at

front of engine. Locate the probe perpendicular

against nose of crankshaft (Fig. 32).

(2) Move crankshaft all the way to the rear of its

travel.

(3) Zero the dial indicator.

(4) Move crankshaft all the way to the front and

read the dial indicator. Refer to Engine Specifica-

tions.

VALVE AND VALVE SEAT—REFACING

The intake and exhaust valves have a 44.5 to 45

degree face angle. The valve seats have a 45 to 45.5

degree face angle. The valve face and valve seat

angles are shown in (Fig. 33).

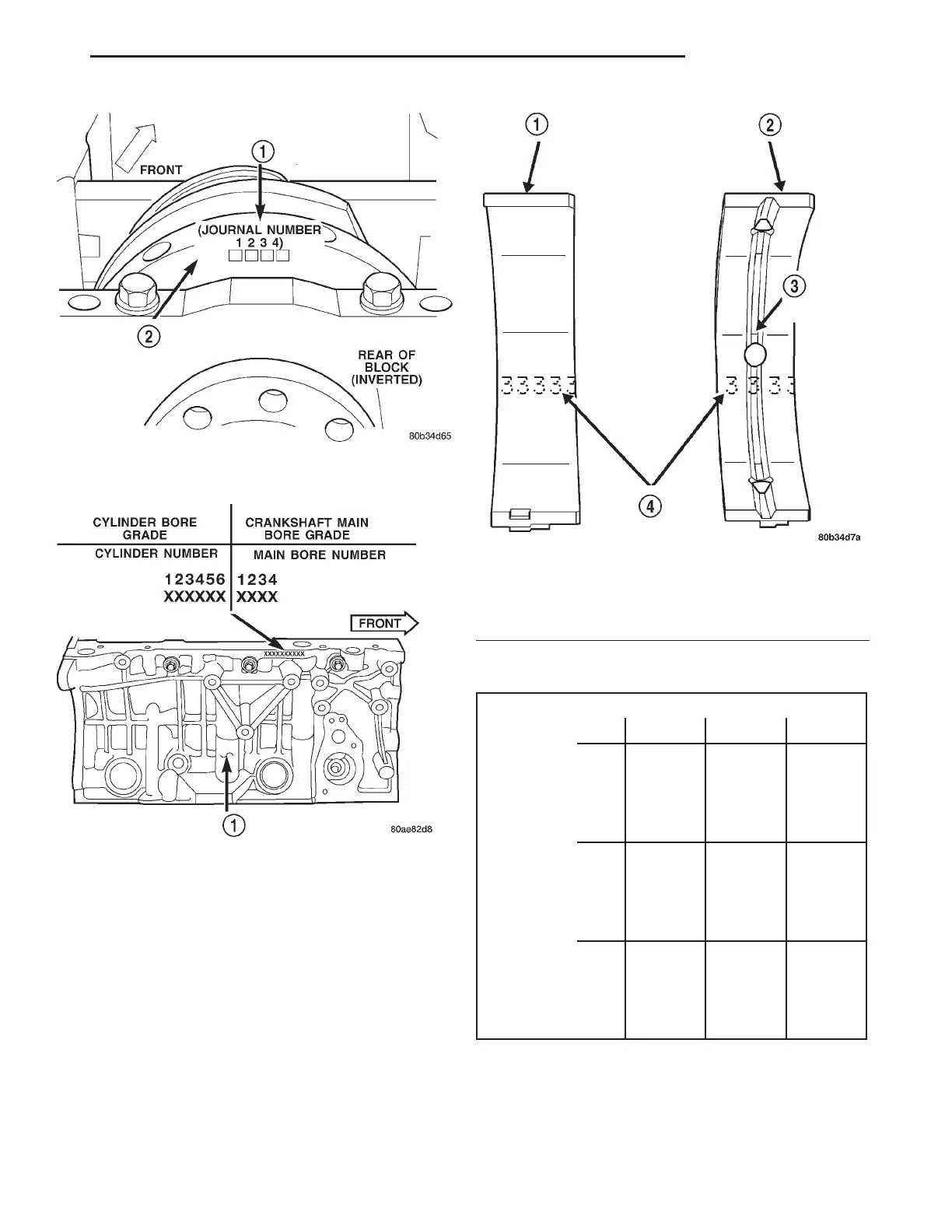

Fig. 29 Crankshaft Main Journal Grade Marking

Location

Fig. 30 Cylinder Block Main Bore Grade Marking

Location

Fig. 31 Main Bearing Grade Marks

1 – LOWER MAIN BEARING

2 – UPPER MAIN BEARING

3 – OIL FEED HOLE AND GROOVE

4 – GRADE SELECTION INK MARKS

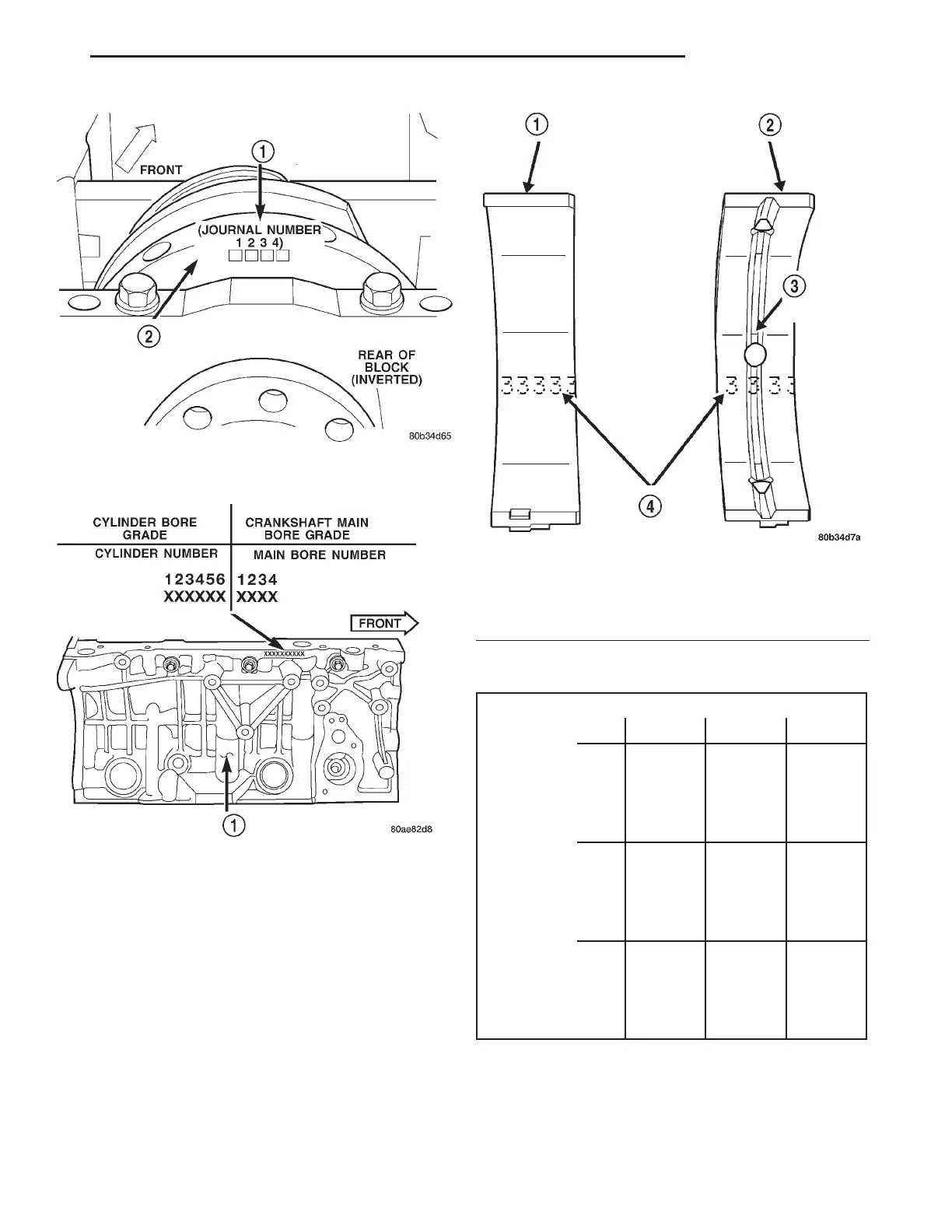

MAIN BEARING SELECTION CHART—2.7L

Main Bearing Bore Grade Mark

123

Crankshaft

Main

Journal

Grade Mark

1

(3)

standard

(2)

+0.003

mm

(+0.0002

in.)

(1)

+0.006

mm

(+0.0003

in.)

2

(4)

-0.003

mm

(-0.0002)

(3)

standard

(2)

+0.003

mm

(+0.0002

in.)

3

(5)

-0.006

mm

(-0.0003

in.)

(4)

-0.003

mm

(-0.0002

in.)

(3)

standard

LH 2.7L ENGINE 9 - 27

SERVICE PROCEDURES (Continued)

Loading...

Loading...