INSTALLATION

(1) Install the ICU back in the vehicle and attach

it to its mounting bracket. Tighten the 3 ICU mount-

ing bolts to 11 N·m (97 in. lbs.).

(2) Reinstall the inner fender splash shield.

(3) reinstall the tire and wheel assembly.

(4) Lower the vehicle.

CAUTION: Before installing the 25-way connector

in the CAB be sure that the seal is properly

installed in the connector.

(5) Install the 25-way connector into the socket on

the CAB. The connector is installed using the follow-

ing procedure. Position the 25-way connector in the

socket on the CAB and carefully push it onto CAB as

far as it will go. When connector is fully seated into

the CAB socket push in the connector lock (Fig. 16)

as far as it will go. This will pull the 25-way connec-

tor into the socket on the CAB and lock it in the

installed position.

(6) Install the 4 chassis brake tubes on the HCU

(Fig. 15). Tighten the chassis brake tubes to 17 N·m

(145 in. lbs.).

(7) Install the primary and secondary brake lines

from the master cylinder on the HCU (Fig. 15).

Tighten the primary and secondary brake tubes to 17

N·m (145 in. lbs.).

(8) Reinstall the transmission controller (Fig. 14).

(9) Reattach the washer bottle filler neck to the

radiator support.

(10) Reinstall the speed control servo to its mount-

ing studs and radiator support.

(11) Remove brake pedal positioning tool.

(12) Install the remote ground cable onto the

ground stud located on left shock tower. Install the

remote ground cable attaching nut and tighten to a

torque of 28 N·m (250 in. lbs.).

NOTE: The ICU may need to be initialized, using

the DRB scan tool, after installation.

(13) Bleed the base brakes and the ABS brakes

hydraulic system. Refer to the Bleeding ABS System

in this section of the manual for the proper bleeding

procedure.

(14) Road test vehicle to ensure proper operation

of the base and ABS systems.

WHEEL SPEED SENSOR (FRONT)

REMOVAL

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the tire and wheel assembly from the

vehicle.

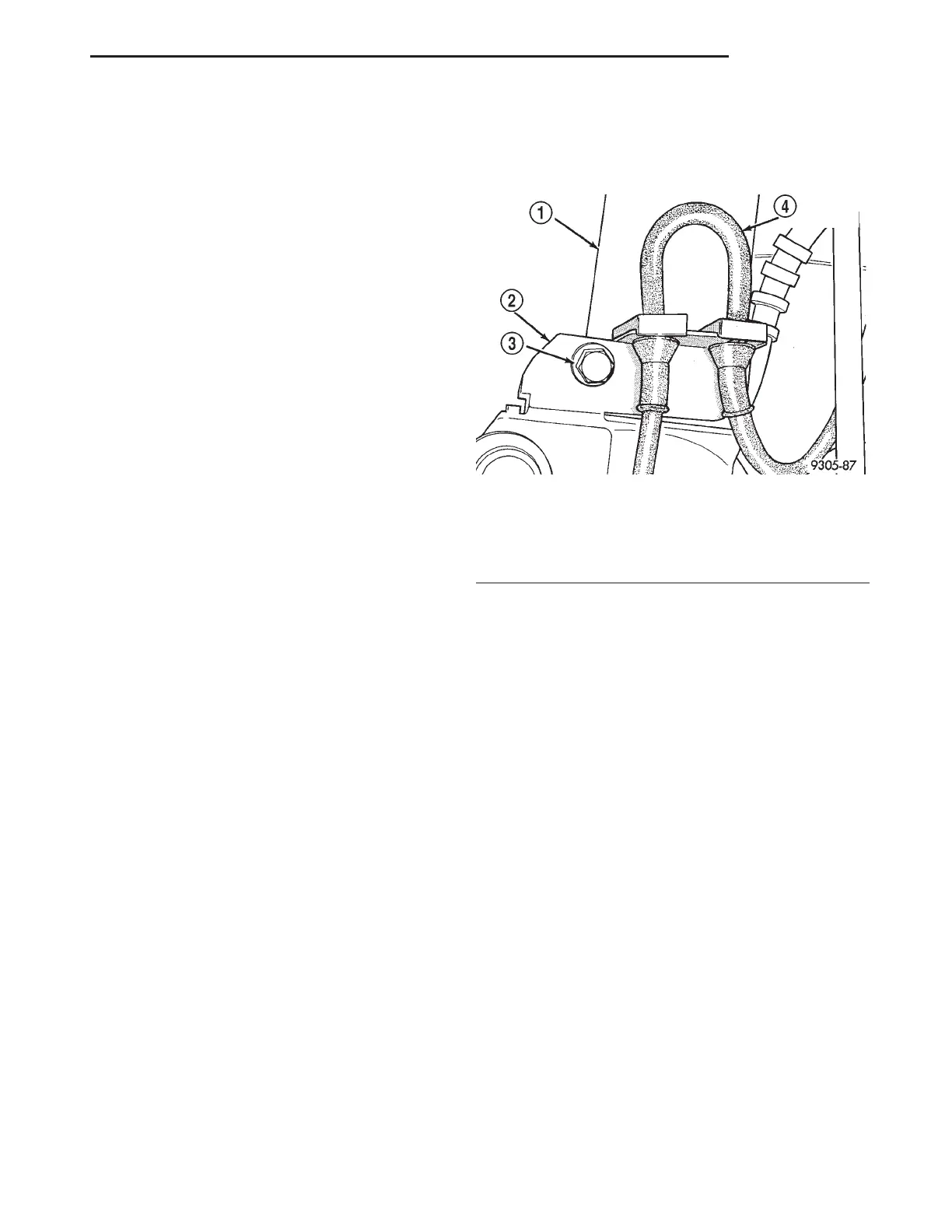

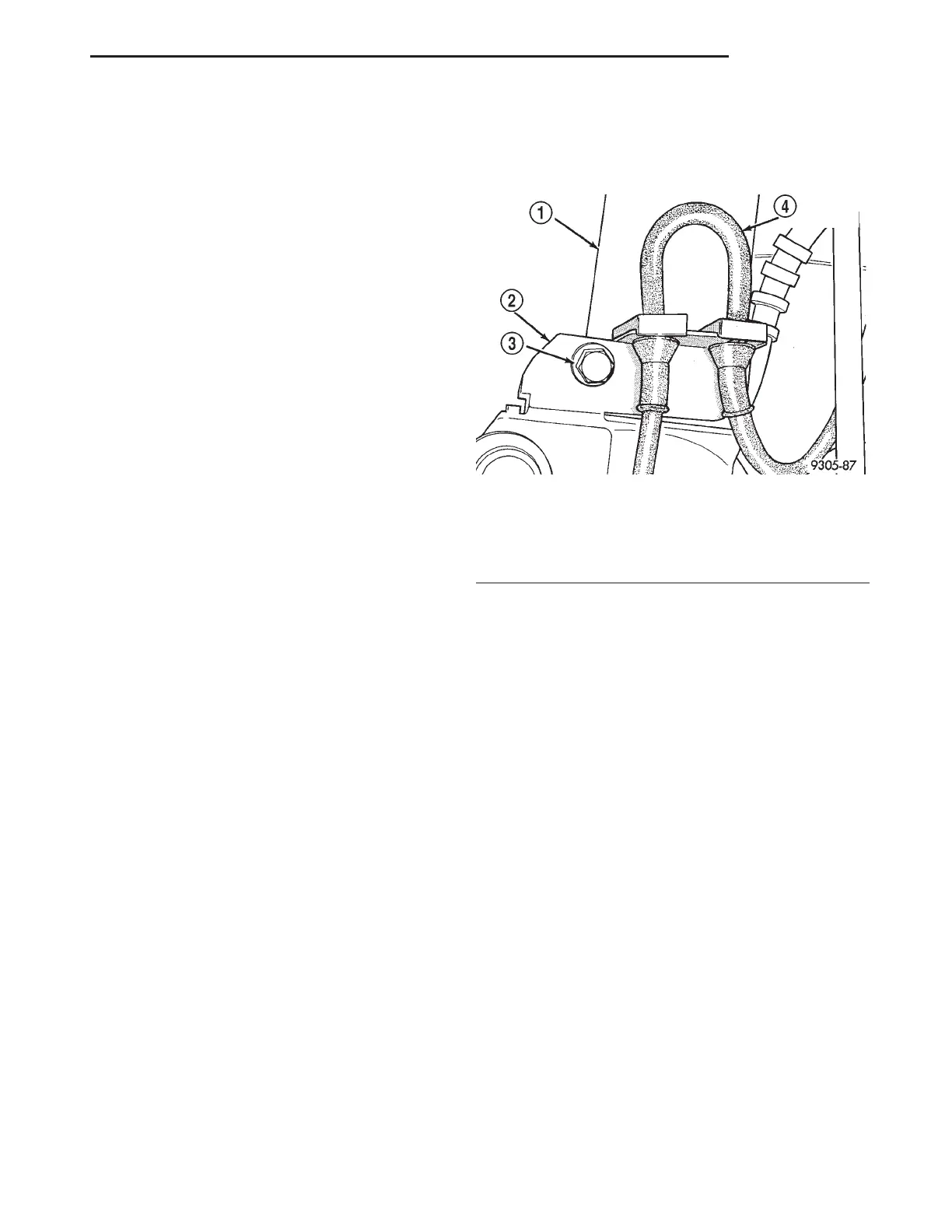

(3) Remove bolt securing the speed sensor cable

routing bracket (Fig. 17) to the strut assembly.

(4) Remove retainer, holding the speed sensor seal-

ing grommet, from the inner fender. pull the grom-

met out, then unplug the speed sensor cable from the

vehicle wiring harness

(5) Remove bolt attaching speed sensor to steering

knuckle. Carefully remove speed sensor head from

steering knuckle. If sensor is seized in place by cor-

rosion, tap the edge of the sensor ear with a hammer

and brass punch (Fig. 18), working it side to side.

CAUTION: If speed sensor head locating pin has

seized to the steering knuckle, do not attempt to

remove speed sensor head by grasping with pliers

and turning. This will damage the speed sensor

head. Use only the following procedure.

INSTALLATION

CAUTION: Proper installation of wheel speed sen-

sor cables is critical to continued system operation.

Be sure that cables are installed in retainers. Fail-

ure to install cables in retainers as shown in this

section may result in contact with moving parts

and/or over extension of cables, resulting in an

open circuit.

(1) Connect the wheel speed sensor cable connector

to the vehicle wiring harness.

(2) Install the speed sensor cable assembly grom-

met into the front inner fender. Install speed sensor

Fig. 17 Speed Sensor Cable Routing Bracket

1 – STRUT ASSEMBLY

2 – ROUTING BRACKET

3 – SCREW

4 – SPEED SENSOR CABLE

LH BRAKES 5 - 71

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...