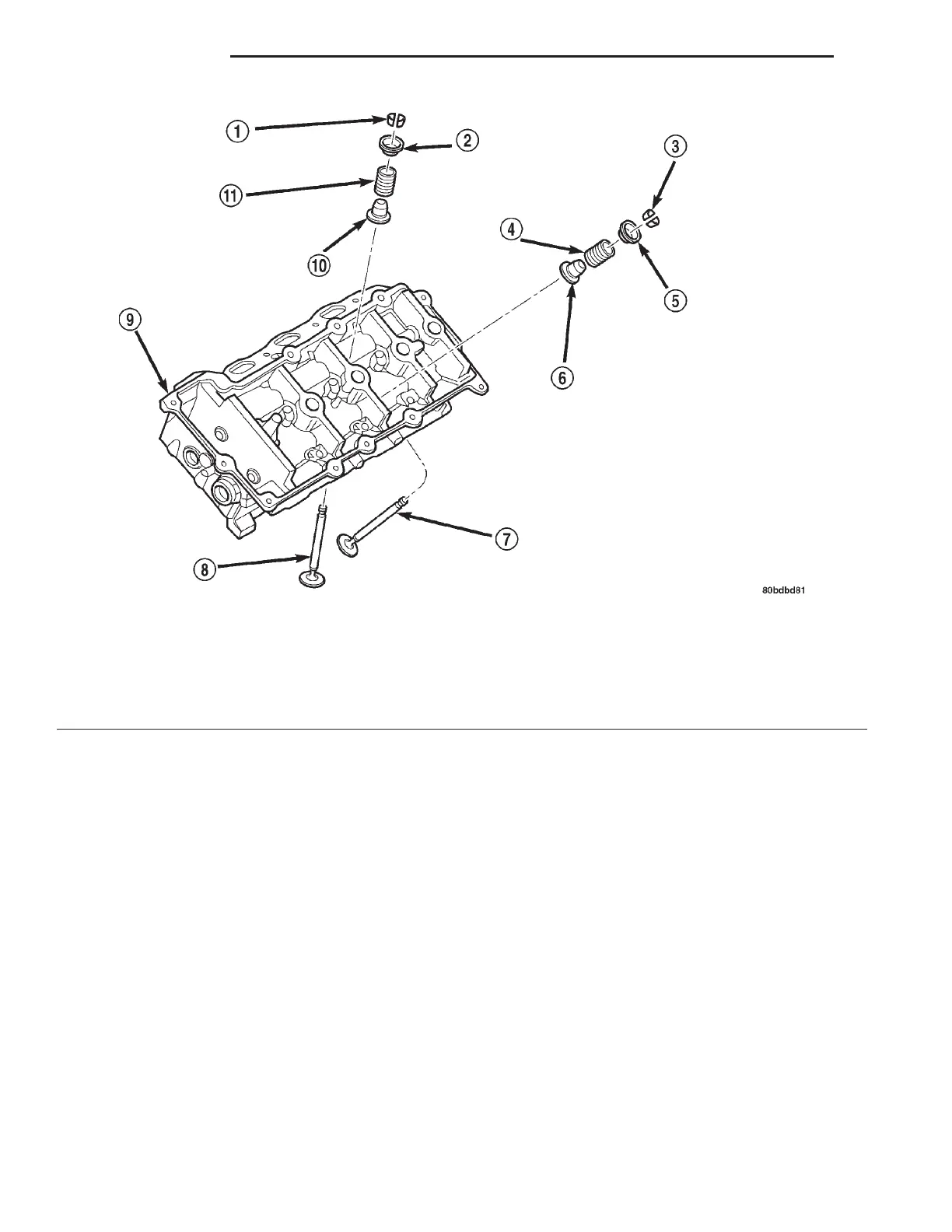

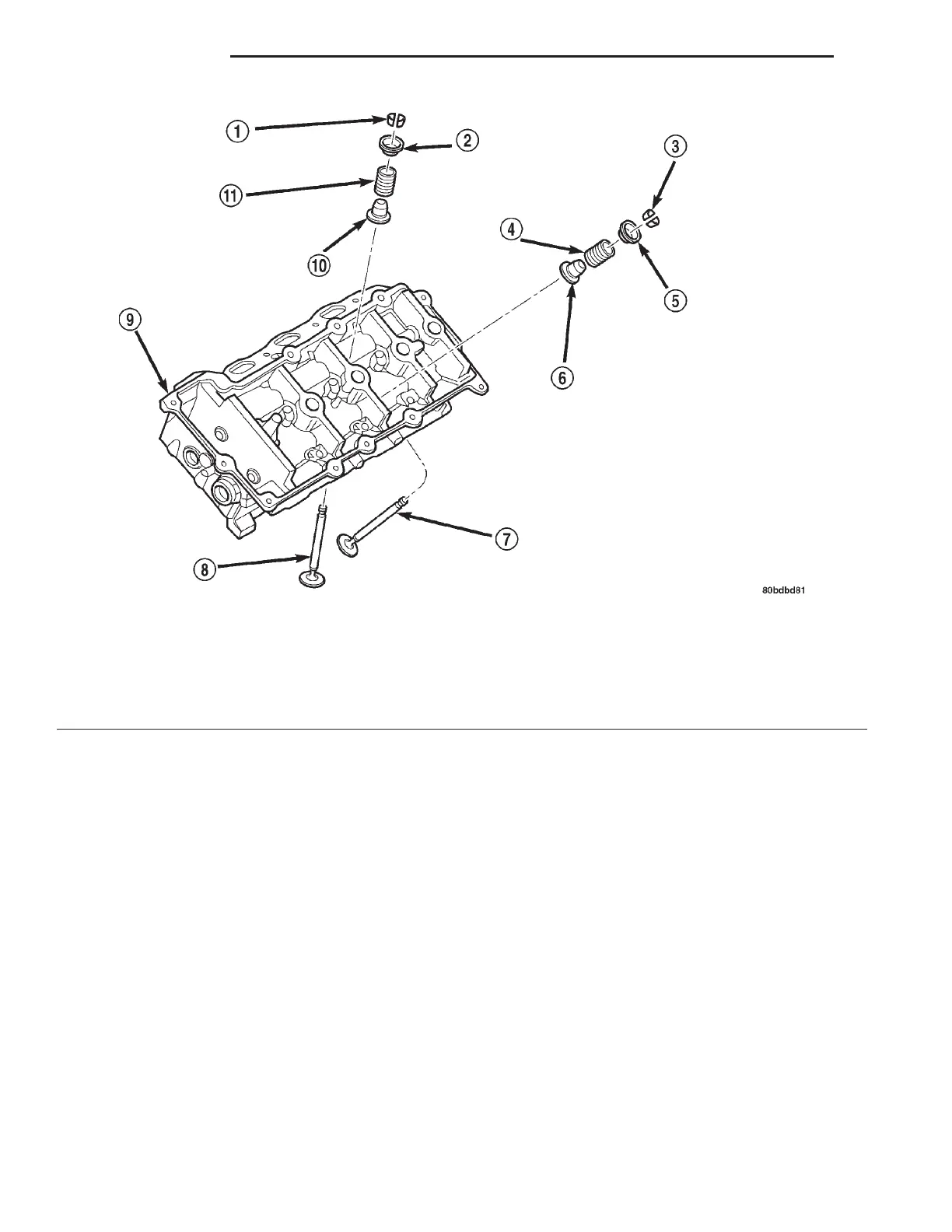

VALVE SPRINGS

DESCRIPTION

The valve springs are made from high strength,

chrome-silicon steel (Fig. 6). The springs are common

for intake and exhaust applications. The valve spring

seat is integral with the valve stem seal, which incor-

porates a garter spring to maintain consistent lubri-

cation control to the valve stem.

OPERATION

The valve spring returns the valve against its seat

for a positive seal of the combustion chamber.

TIMING DRIVE SYSTEM

DESCRIPTION

The timing drive system has been designed to pro-

vide quiet performance and reliability to support a

NON free-wheeling engine. The system consists of a

primary and secondary chain drive.

The primary timing chain drive (Fig. 7) uses a

single, double-flexure, inverted tooth type chain. The

primary chain drives both of the intake camshafts

directly from a sprocket mounted on the crankshaft.

In addition, the water pump is driven by the “back

side” of the primary chain, necessitating the double-

flexure type chain.

The chain is controlled by three fixed chain guides

and a pivoting tensioner arm (Fig. 7). These guides

utilize low-friction and long wearing nylon plastic

wear faces. To tension the primary chain, a fully

automatic spring-loaded, engine oil-fed, hydraulic

tensioner is used. The tensioner is mounted in the

right cylinder head with the plunger contacting the

pivoting tensioner arm. A mechanical ratchet mecha-

nism inside the tensioner prevents excessive chain

slack upon engine start-up as the chain wears. The

tensioner is designed with an internal oil reservoir to

assure noise-free performance, even during engine

start-up before oil pressure reaches the tensioner.

Fig. 6 Cylinder Head, Valves, and Springs

1 – VALVE KEEPER

2 – SPRING RETAINER

3 – VALVE KEEPER

4 – VALVE SPRING-EXHAUST

5 – SPRING RETAINER

6 – VALVE STEM SEAL

7 – VALVE-EXHAUST

8 – VALVE-INTAKE

9 – CYLINDER HEAD

10 – VALVE STEM SEAL

11 – VALVE SPRING-INTAKE

9 - 6 2.7L ENGINE LH

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...