(14) Install crankshaft sprocket. Refer to proce-

dure in this section.

(15) Install timing chain. Refer to procedure in

this section.

(16) Install timing chain cover.

(17) Install cylinder head covers.

(18) Install idler pulley bracket for accessory drive

belt.

(19) Install oil pick-up tube and O-ring.

(20) Install oil pan and oil filter.

(21) Install oil dipstick tube.

(22) Install engine assembly.

(23) Fill engine crankcase with proper oil to cor-

rect level.

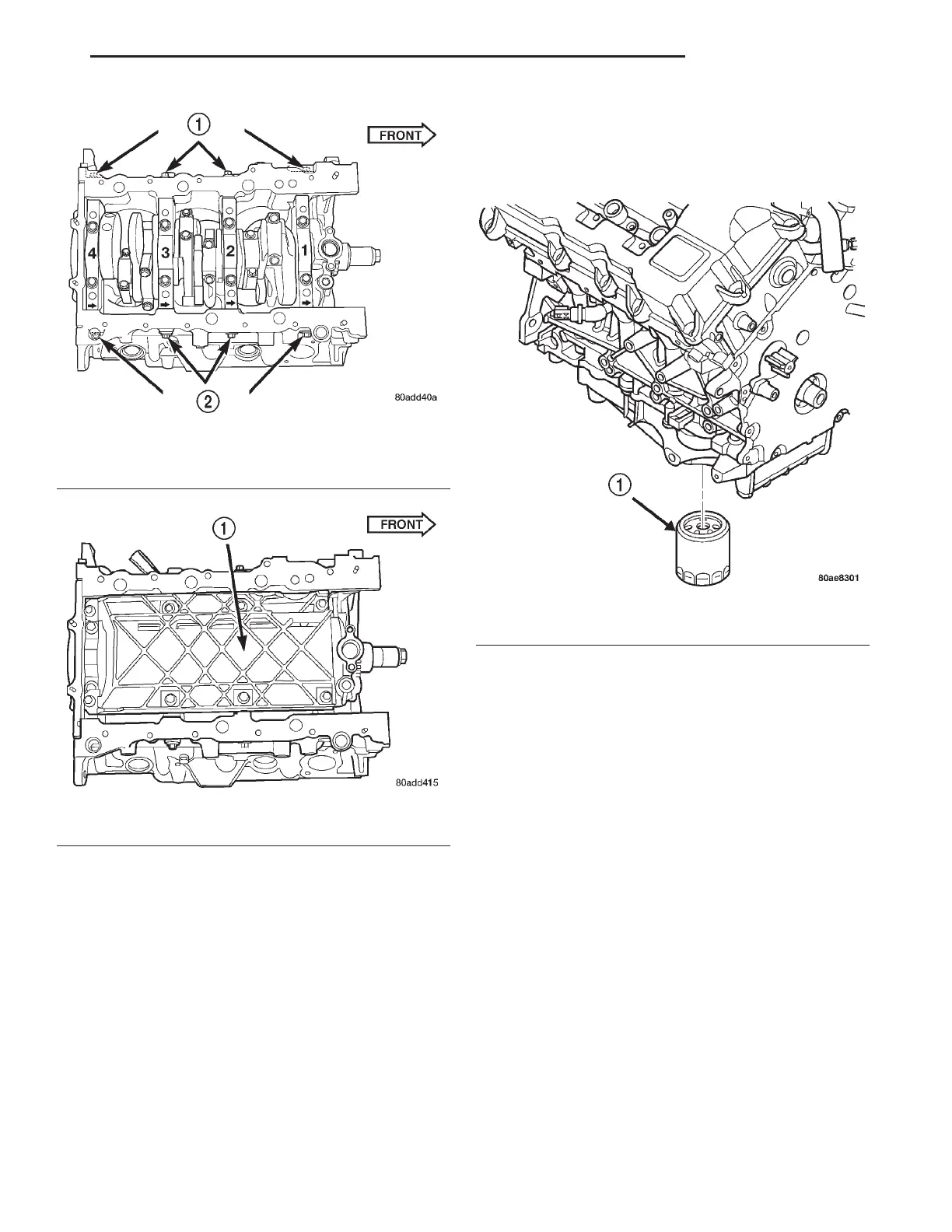

OIL FILTER

(1) Remove oil filter using suitable oil filter

wrench (Fig. 92). Dispose of oil filter following envi-

romental guidelines.

(2) Wipe filter base clean, then inspect gasket seal-

ing surface.

(3) Lubricate gasket of new filter with clean

engine oil.

(4) Install oil filter and tighten to 20 N·m (15 ft.

lbs.) of torque after gasket contacts base. Use filter

wrench if necessary.

(5) Fill crankcase with proper engine oil to correct

level if drained. Start engine and check for leaks.

OIL PUMP

REMOVAL

The oil pump pressure relief valve can be serviced

by removing the oil pan.

(1) Refer to procedures in this section for removing

the following components:

• Crankshaft Damper

• Timing Chain Cover

• Timing Chain

• Crankshaft Sprocket

• Oil Pan

(2) Remove oil pick-up tube and O-ring (Fig. 94).

(3) Ensure that crankshaft position is at 60° ATDC

of No.1 cylinder, or crankshaft sprocket mark aligns

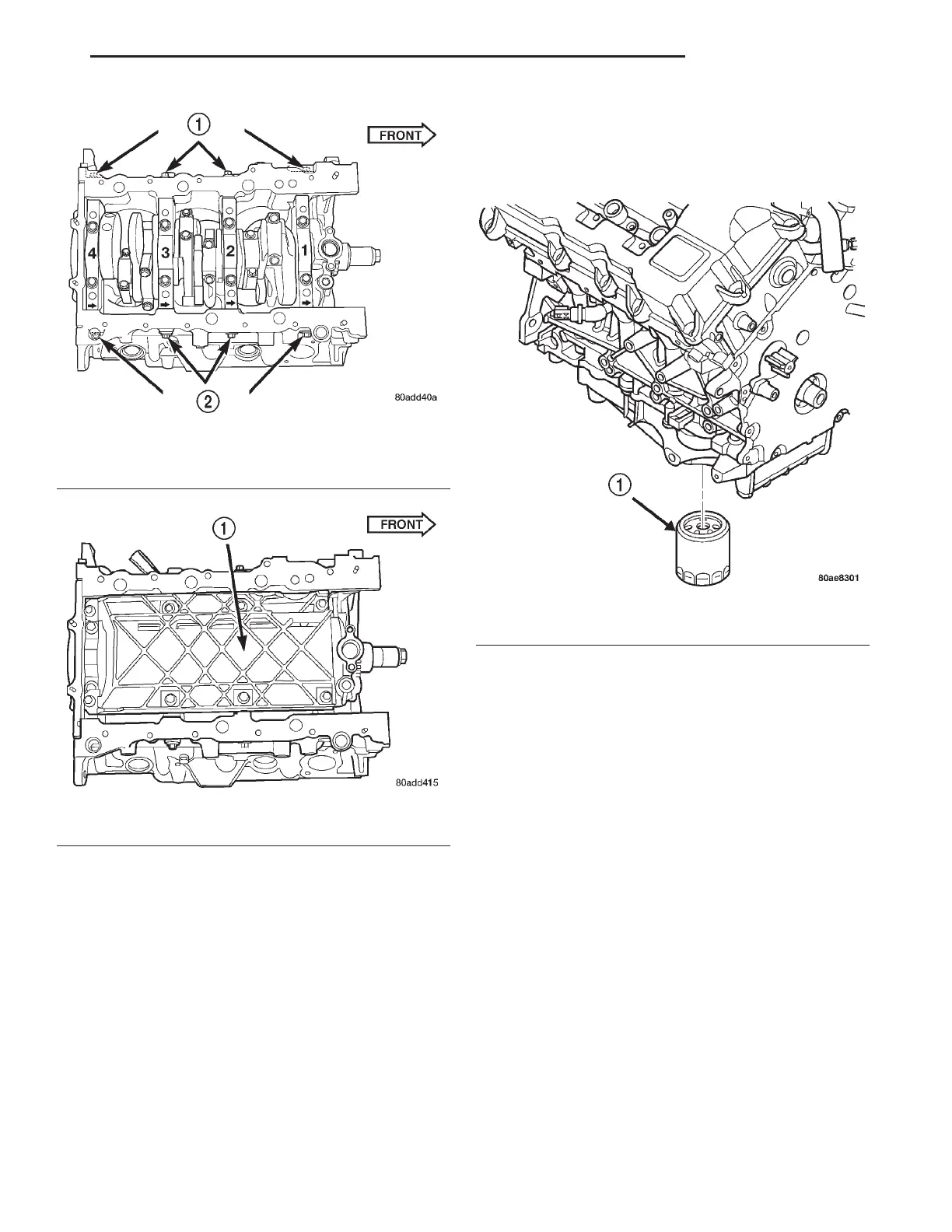

Fig. 90 Main Bearing Cap Identification

1 – TIE BOLTS

2 – TIE BOLTS

Fig. 91 Windage Tray

1 – STRUCTURAL WINDAGE TRAY

Fig. 92 Engine Oil Filter

1 – OIL FILTER

LH 2.7L ENGINE 9 - 57

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...