lubricants usage. Such as API GL-5 and SAE 80W-

90.

LUBRICANTS AND GREASES

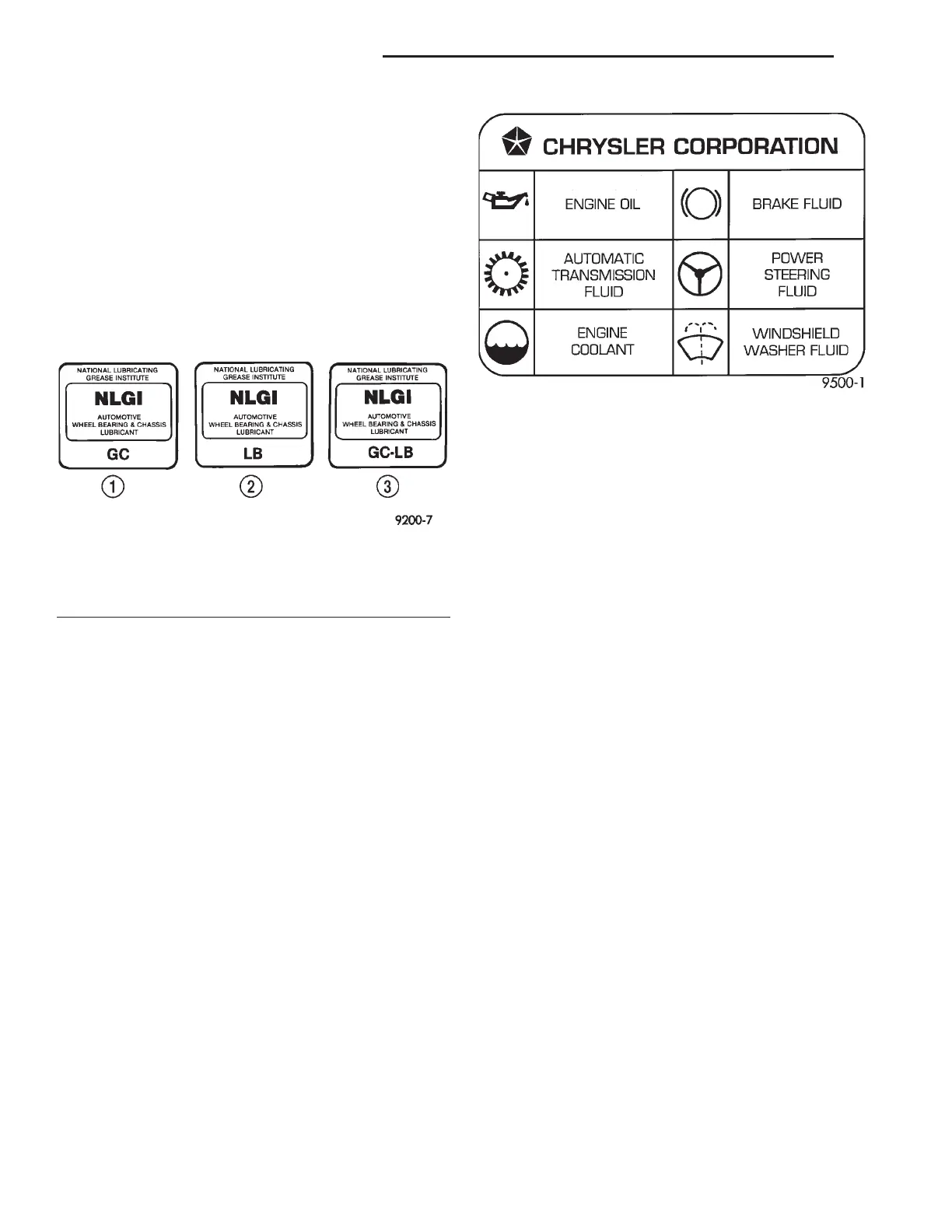

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 2) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

“G”. Chassis lubricant is identified by the latter “L”.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

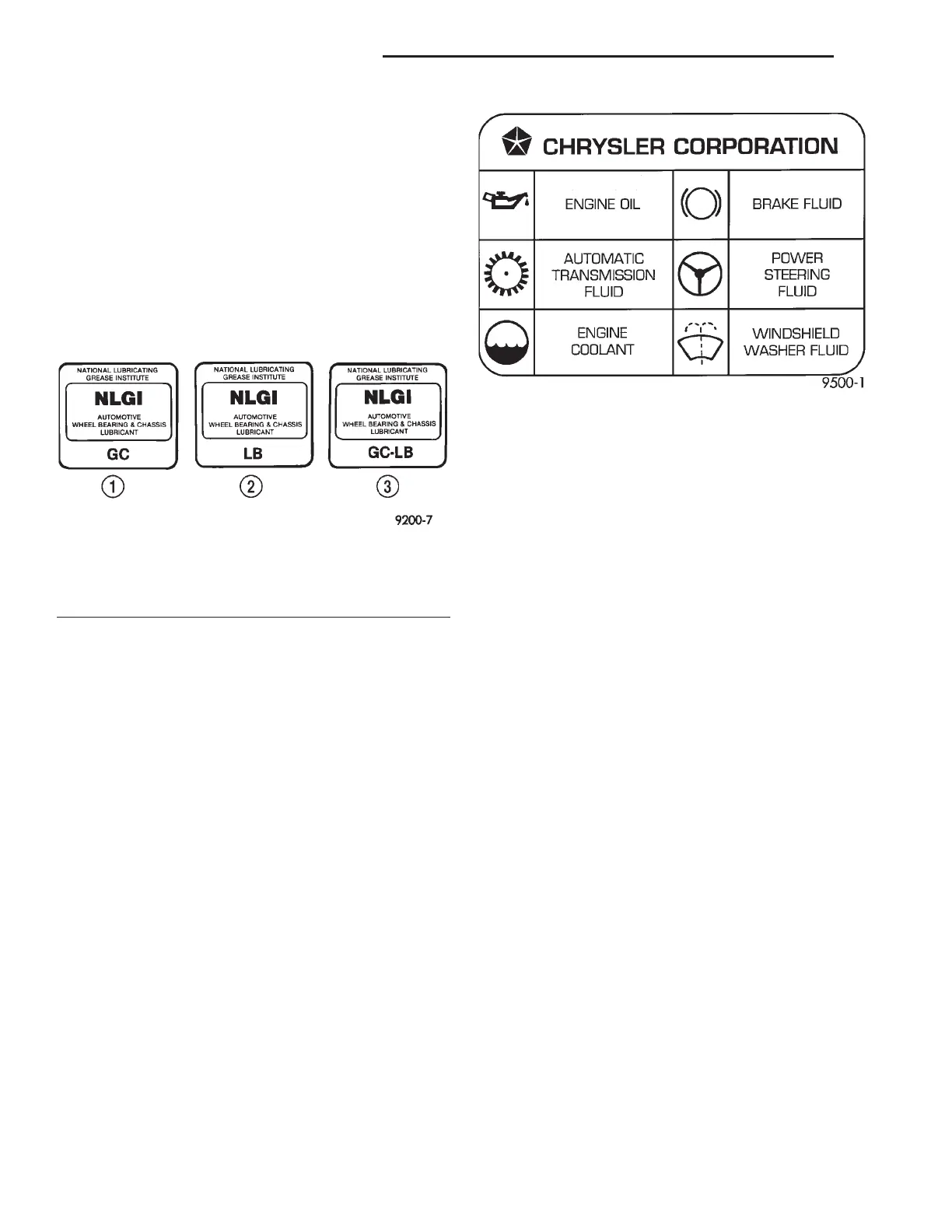

INTERNATIONAL SYMBOLS

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 3).

FLUID CHECK/FILL POINTS AND LUBRICATION

LOCATIONS

The fluid check/fill points and lubrication locations

are located in each applicable Sections.

LUBRICATION POINT LOCATIONS

Lubrication point locations are located in each

applicable Sections.

SPECIFICATIONS

FLUID CAPACITIES

Fuel Tank ..................... 68L(18gal.)

Engine Oil – 2.7 L Engine with Oil Filter . . . 4.7 L

(5.0 qts.)

Engine Oil – 3.2 L Engine with Oil Filter . . . 4.7 L

(5.0 qts.)

Engine Oil – 3.5 L Engine with Oil Filter . . . 4.7 L

(5.0 qts.)

Cooling System – 2.7 L Engine .... 8.9L(9.4 qts.)

Cooling System – 3.2 L Engine .... 8.9L(9.4 qts.)

Cooling System – 3.5 L Engine .... 8.9L(9.4 qts.)

Automatic Transaxle – Estimated Service

Fill ........................ 4.3L(4.5 qts.)

Automatic Transaxle – Overhaul Fill Capacity

with Torque Converter Empty . . . 9.4 L (9.9 qts.)

Differential ..................... 0.95 L (1 qt.)

Fig. 2 NLGI Symbol

1 – WHEEL BEARINGS

2 – CHASSIS LUBRICATION

3 – CHASSIS AND WHEEL BEARINGS

Fig. 3 International Symbols

0 - 2 LUBRICATION AND MAINTENANCE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...