(4) Install outer C/V joint seal boot retaining

clamp, onto interconnecting shaft. Install replace-

ment outer C/V joint sealing boot onto interconnect-

ing shaft. Outer C/V joint seal boot MUST be

positioned on interconnecting shaft, so only the

thinnest (sight) groove on interconnecting shaft

is visible (Fig. 35).

(5) Clamp sealing boot on interconnecting shaft

using Crimper, Special Tool C-4975 and the following

procedure. Place crimping tool C-4975 over bridge of

clamp (Fig. 36). Tighten nut on crimping tool C-4975

until jaws on tool are closed completely together, face

to face (Fig. 37).

CAUTION: Seal must not be dimpled, stretched or

out of shape in any way. If seal is NOT shaped cor-

rectly, equalize pressure in seal and shape it by

hand.

(6) Position outer C/V joint seal boot, into boot

retaining groove on outer C/V joint housing. Install

seal boot to outer C/V joint retaining clamp evenly on

sealing boot.

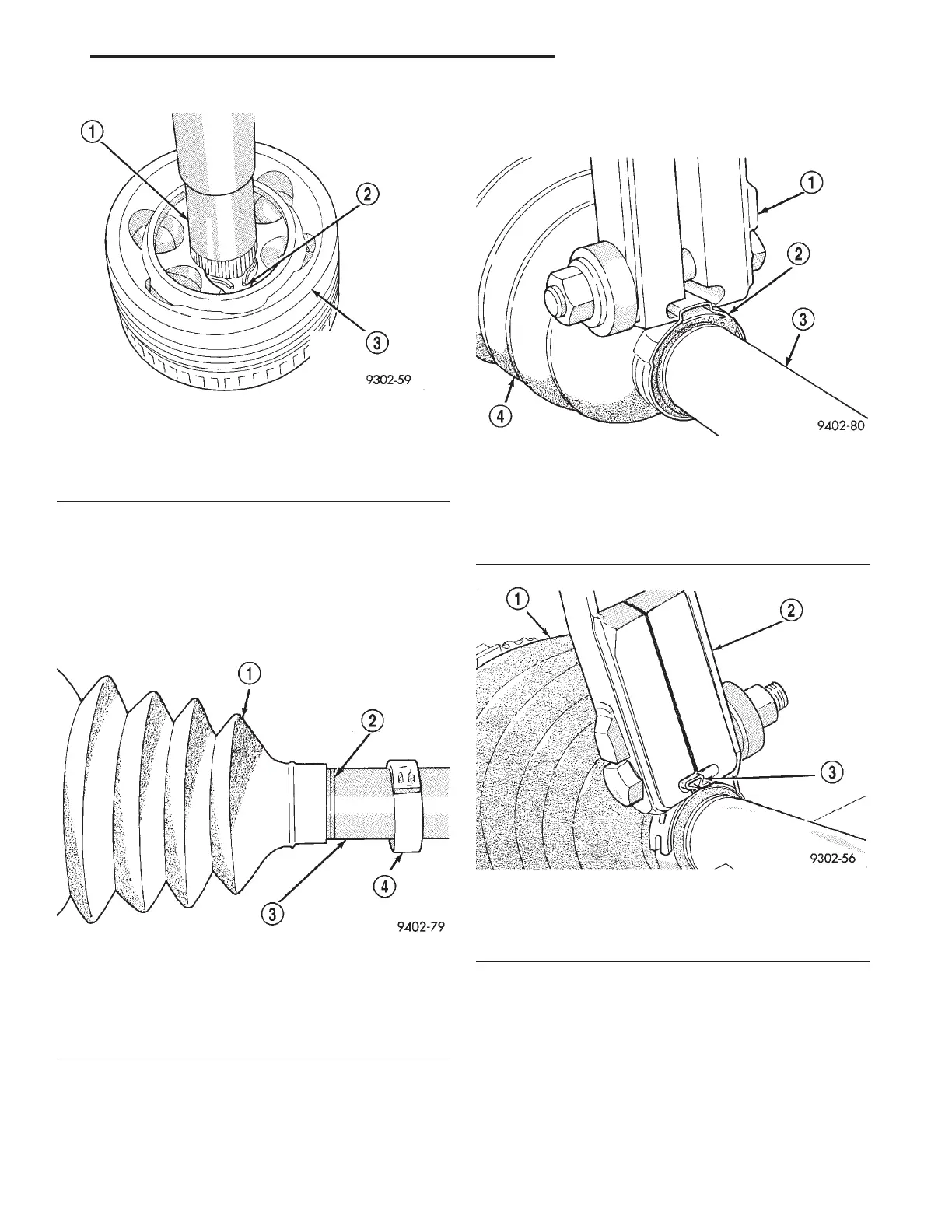

Fig. 34 Outer C/V Joint Installed On Interconnecting

Shaft

1 – INTERCONNECTING SHAFT

2 – RETAINING SNAP RING

3 – OUTER C/V JOINT ASSEMBLY

Fig. 35 Seal Boot Correctly Positioned On

Interconnecting Shaft

1 – SEALING BOOT

2 – INTERCONNECTING SHAFT THINNEST GROOVE

3 – INTERCONNECTING SHAFT

4 – BOOT CLAMP

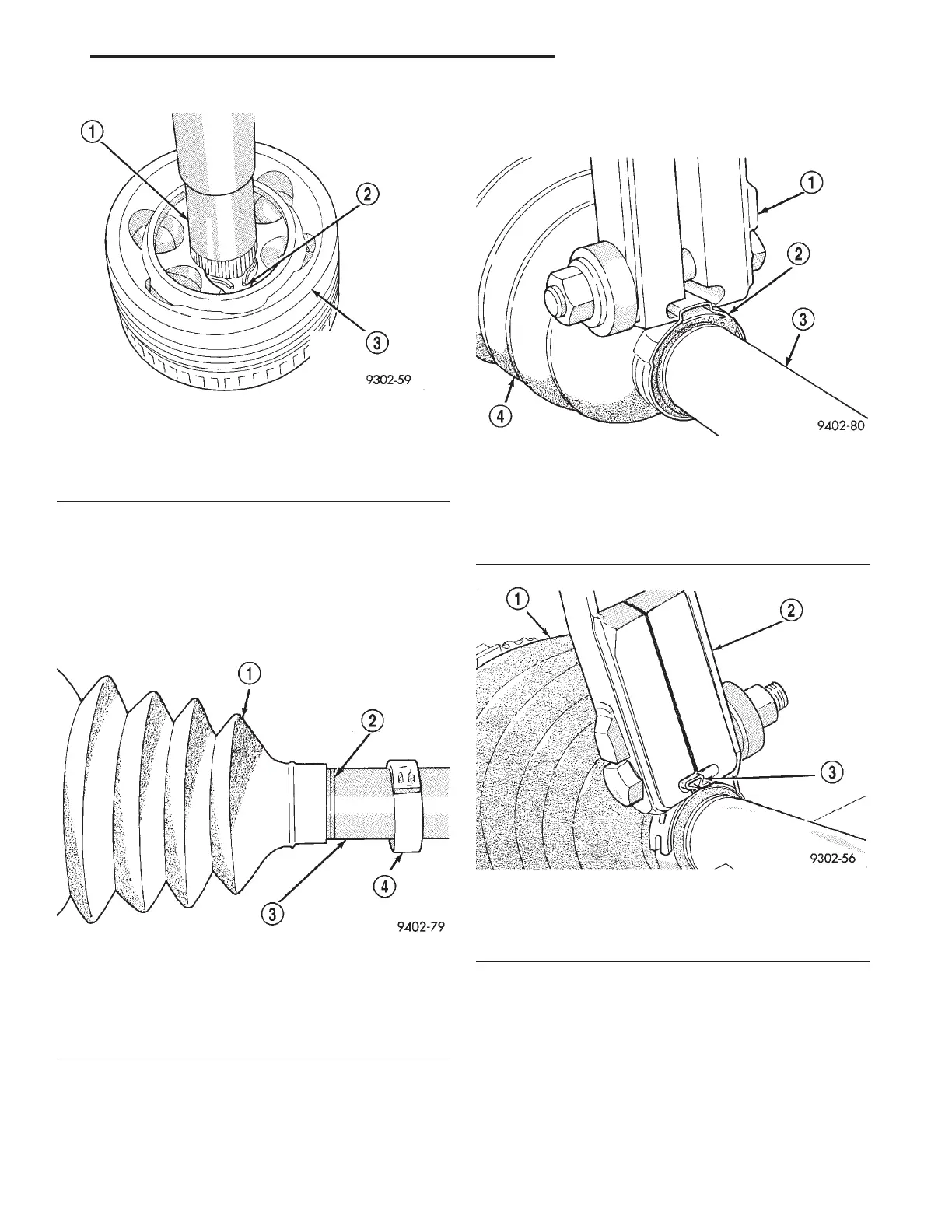

Fig. 36 Crimping Tool Installed On Sealing Boot

Clamp

1 – SPECIAL TOOL C-4975

2 – SEALING BOOT CLAMP

3 – INTERCONNECTING SHAFT

4 – SEALING BOOT

Fig. 37 Sealing Boot Retaining Clamp Installed

1 – SEALING BOOT

2 – SPECIAL TOOL C-4975

3 – CLAMP BRIDGE

LH DIFFERENTIAL AND DRIVELINE 3 - 15

DISASSEMBLY AND ASSEMBLY (Continued)

Loading...

Loading...