CONDITION POSSIBLE CAUSE CORRECTION

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.

1. BATTERY

DISCHARGED OR

FAULTY.

2. STARTING CIRCUIT

WIRING FAULTY.

3. STARTER ASSEMBLY

FAULTY.

4. ENGINE SEIZED.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.

1. REFER TO GROUP 8A, BATTERY. CHARGE OR REPLACE

BATTERY AS NECESSARY.

2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. REFER TO GROUP 9 ENGINE, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. INSPECT FOR LOOSE CONNECTIONS.

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.

1. BROKEN TEETH ON

STARTER RING GEAR.

2. STARTER ASSEMBLY

FAULTY.

1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.

1. STARTER

IMPROPERLY

INSTALLED.

2. STARTER RELAY

FAULTY.

3. IGNITION SWITCH

FAULTY.

4. STARTER ASSEMBLY

FAULTY.

5. FAULTY TEETH ON

RING GEAR.

1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. REFER TO IGNITION SWITCH TEST, IN GROUP 8D,

IGNITION SYSTEM. REPLACE SWITCH, IF NECESSARY.

4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. ROTATE FLYWHEEL 360°, AND INSPECT TEETH.

REMOVAL AND INSTALLATION

SAFETY SWITCHES

For Removal and Installation of the Transmission

Range Sensor, refer to Group 21, Transaxle.

STARTER

REMOVAL

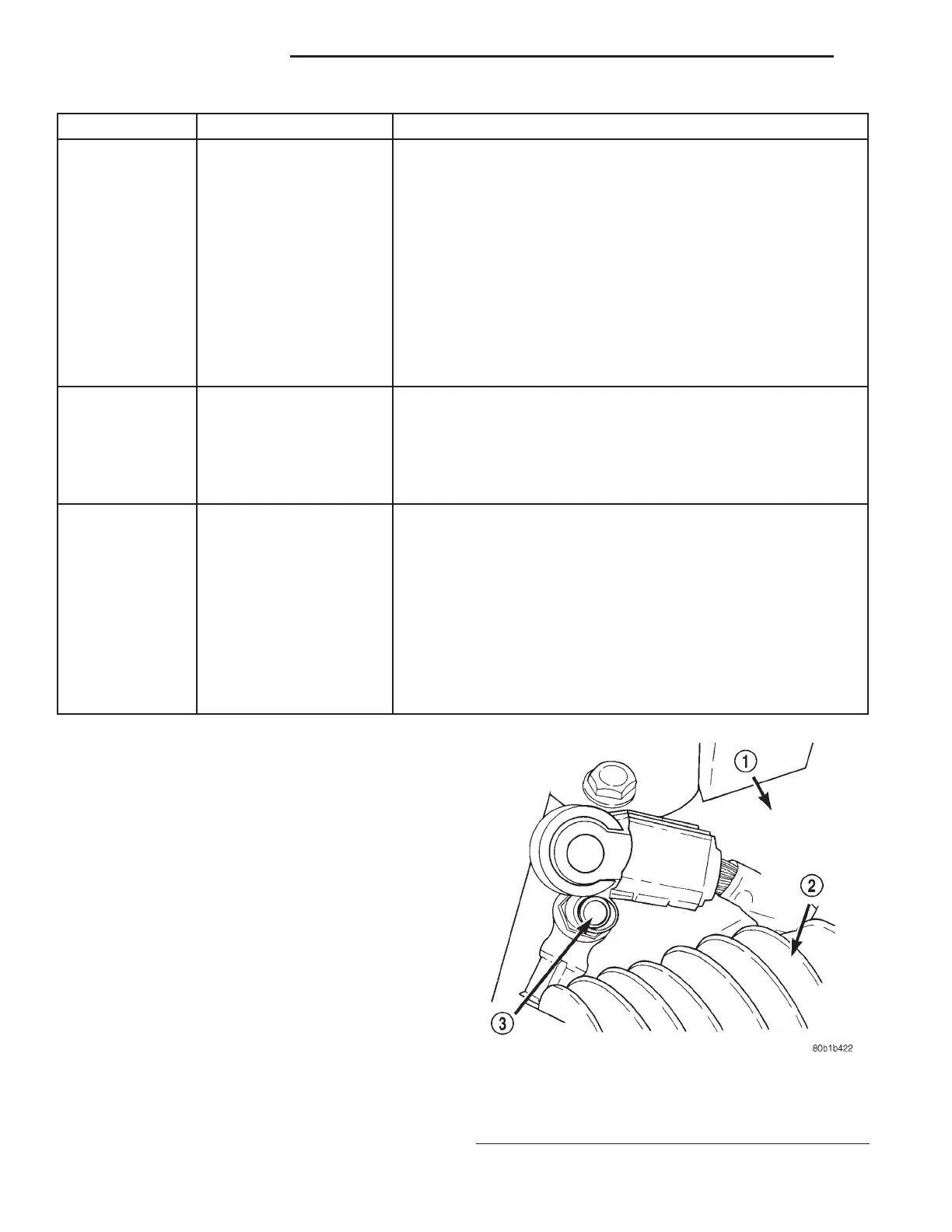

(1) Disconnect and isolate the battery negative

remote cable from remote ground post (Fig. 3).

(2) Raise vehicle.

(3) Remove three bolts attaching starter to engine

(Fig. 4).

(4) Remove battery positive feed wire from starter.

(5) Remove starter solenoid assembly from trans-

mission housing. Position the starter to gain access

to the Connector Positive Assurance (CPA) wiring

connector.

(6) Position jack stand beneath engine and slightly

lift to relieve pressure from left engine mount.

Fig. 3 Negative Battery Cable Remote Terminal

1 – RIGHT STRUT TOWER

2 – AIR CLEANER INLET TUBE

3 – REMOTE TERMINAL

8B - 6 STARTING SYSTEMS LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...