DISASSEMBLY AND ASSEMBLY

OIL PUMP

DISASSEMBLY

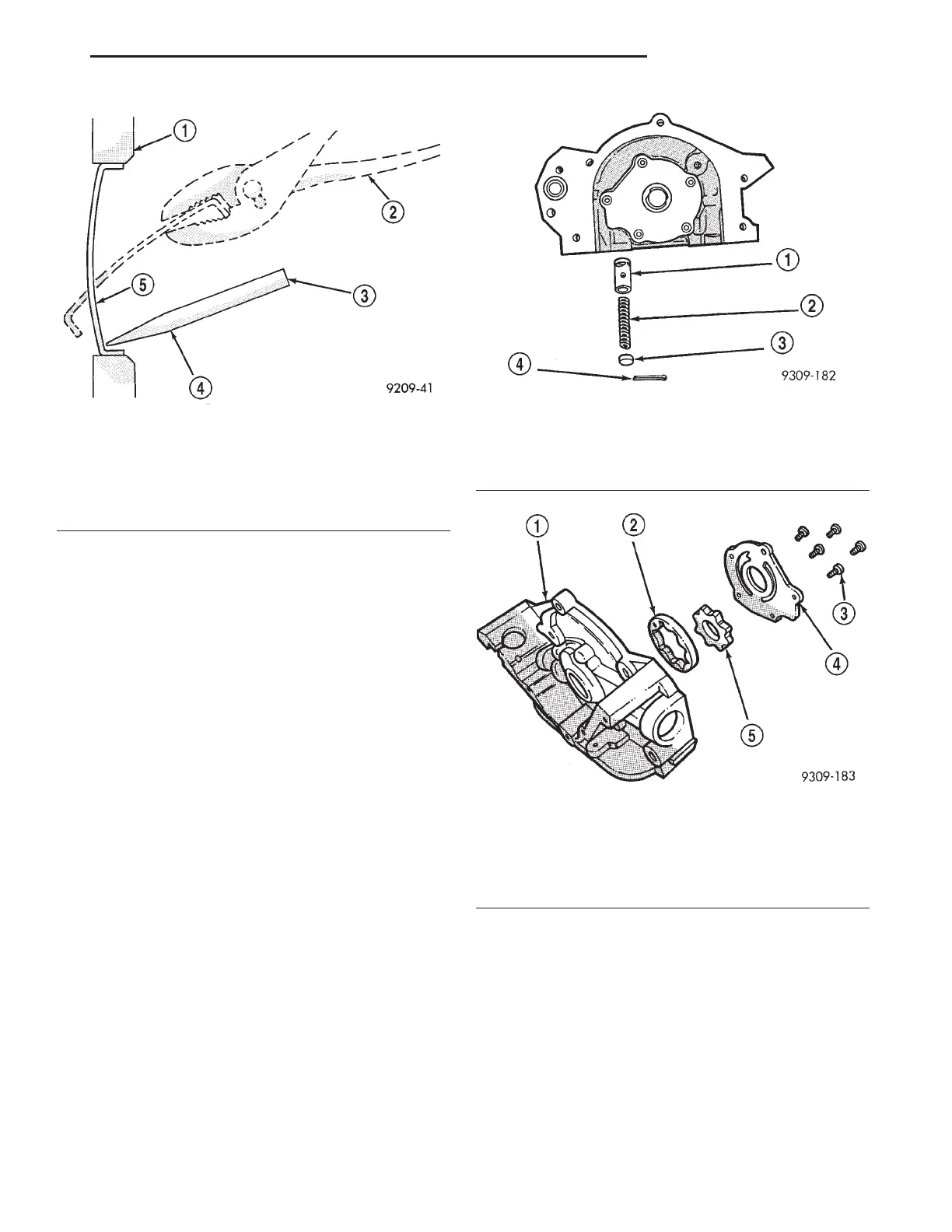

(1) To remove the relief valve, proceed as follows:

(2) Remove cotter pin. Drill a 3.175 mm (1/8 inch.)

hole into the relief valve retainer cap and insert a

self-threading sheet metal screw into cap.

(3) Clamp screw into a vise and while supporting

oil pump body, remove cap by tapping oil pump body

using a soft hammer. Discard retainer cap and

remove spring and relief valve (Fig. 130).

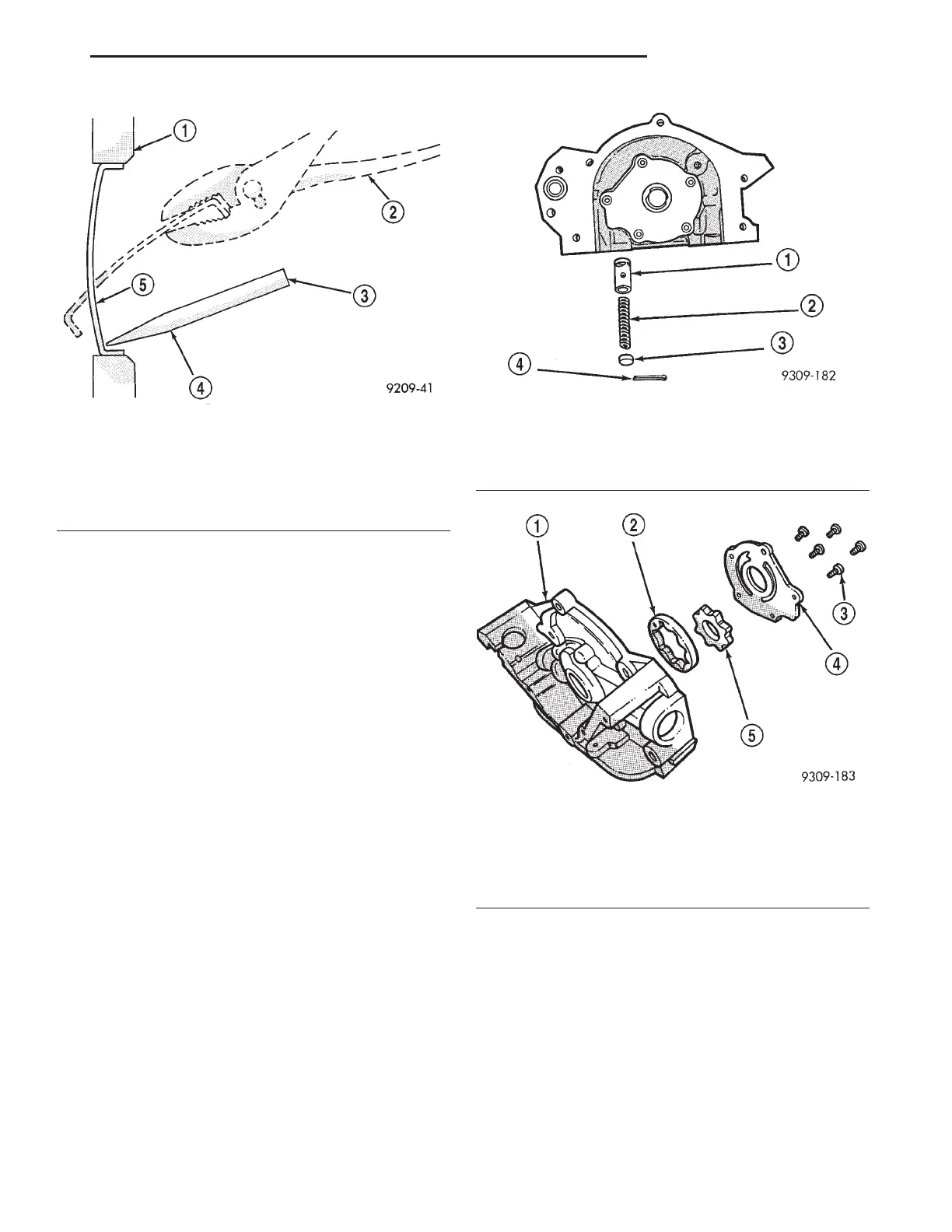

(4) Remove oil pump cover screws, and lift off

cover.

(5) Remove pump rotors.

(6) Wash all parts in a suitable solvent and inspect

carefully for damage or wear (Fig. 131).

ROCKER ARMS AND SHAFT ASSEMBLY

DISASSEMBLY

(1) Remove dowel pin usinga4mmscrew, nut,

spacer, and washer installed into the pin (Fig. 132).

Thread the screw into the pin, then loosen the nut on

the screw. This will pull the dowel out of the shaft

support. Do not reuse dowel pins. Remove the rocker

arms and pedestals in order.

(2) Check the rocker arm mounting portion of the

shafts for wear or damage. Replace if damaged or

heavily worn.

(3) Check shaft oil holes for clogging with small

wire, clean as required.

ASSEMBLY

CAUTION: New dowel pins must be installed when

reassembling.

(1) Install the rocker arms, and pedestals onto the

shaft.

(2) Install dowel pins (Fig. 133). Dowel pins pass

through the pedestal into the exhaust rocker shafts.

Fig. 129 Core Hole Plug Removal

1 – CYLINDER BLOCK

2 – REMOVE PLUG WITH PLIERS

3 – STRIKE HERE WITH HAMMER

4 – DRIFT PUNCH

5 – CUP PLUG

Fig. 130 Oil Pressure Relief Valve

1 – RELIEF VALVE

2 – SPRING

3 – RETAINER CAP

4 – COTTER PIN

Fig. 131 Oil Pump

1 – OIL PUMP BODY

2 – OIL PUMP OUTER ROTOR

3 – SCREWS

4 – OIL PUMP COVER

5 – OIL PUMP INNER ROTOR

LH 3.2/3.5L ENGINE 9 - 137

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...