CRANKSHAFT

DESCRIPTION

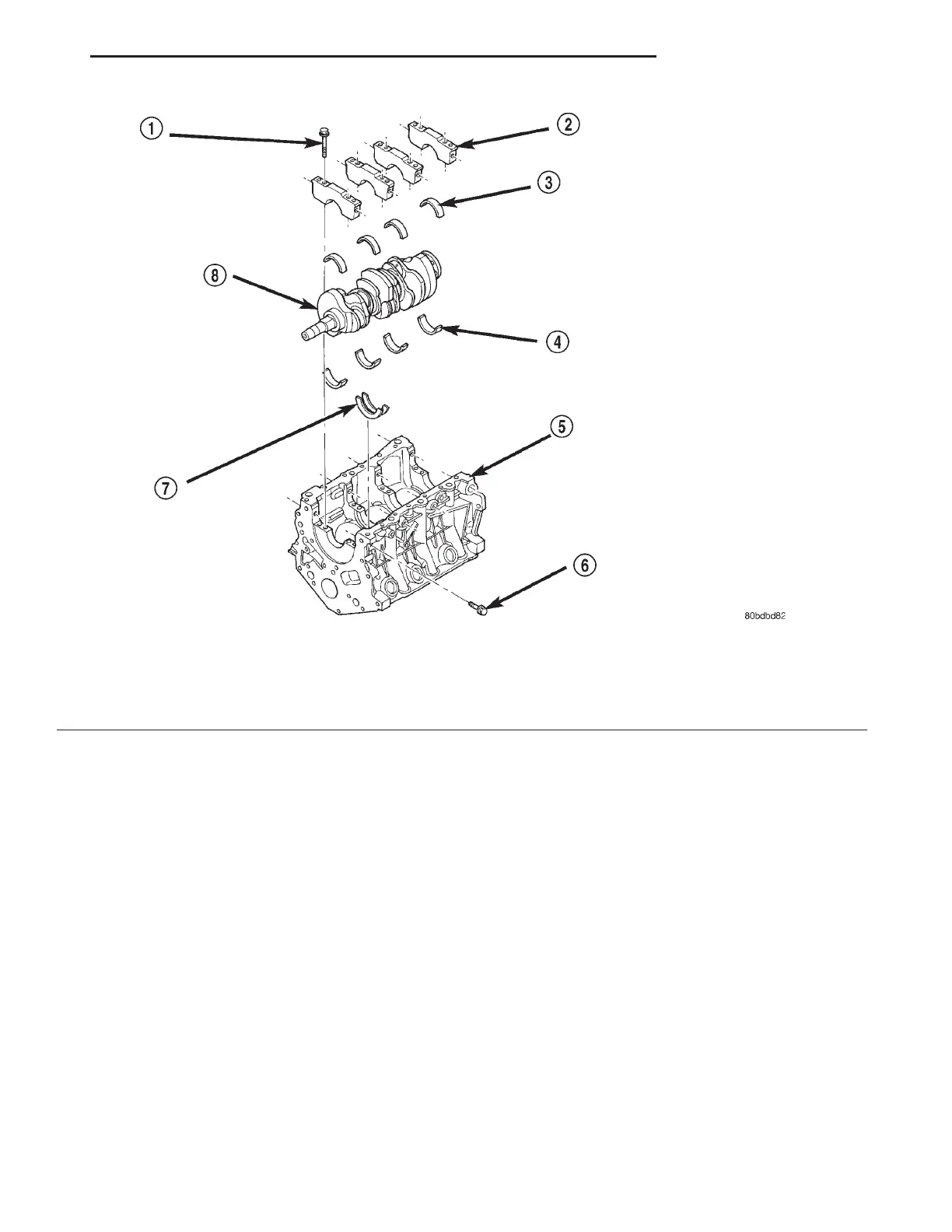

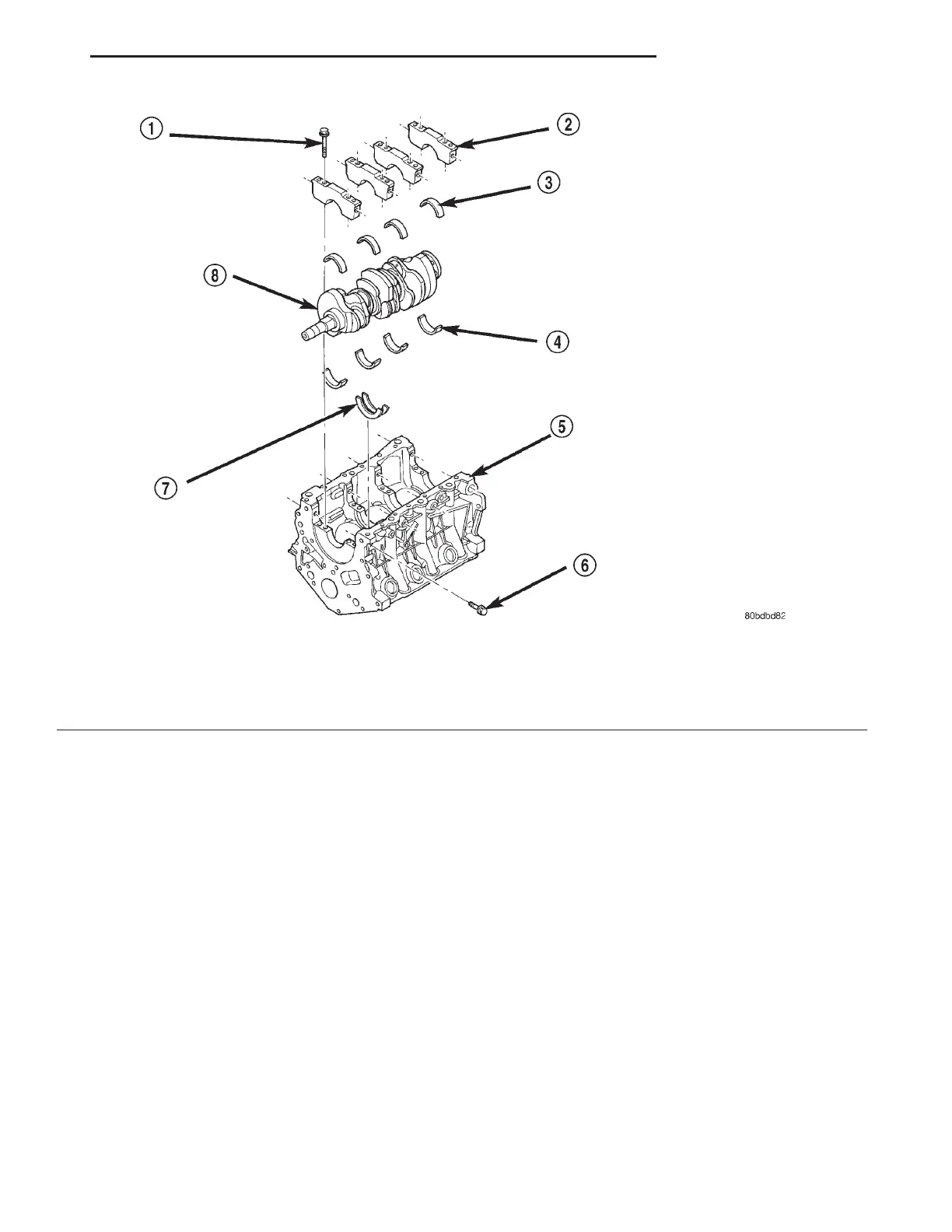

The crankshaft (Fig. 4) is constructed of a forged

micro alloy steel. A six throw, nine counterweight

crankshaft is supported by four select fit main bear-

ings with number two serving as the thrust washer

location. The six separate connecting rod throws are

an even-firing design which reduces torque fluctua-

tions while a torsional vibration damper is used to

control torsion caused vibration of the crankshaft.

Rubber lipped seals are used at front and rear. The

front seal is retained in the oil pump case and the

rear seal is retained in a block-mounted housing.

OPERATION

The crankshaft transfers force generated by com-

bustion within the cylinder to the flywheel or flex-

plate.

Fig. 4 Cylinder Block and Crankshaft

1 – MAIN CAP BOLT - VERTICAL

2 – MAIN CAP

3 – MAIN BEARING - LOWER

4 – MAIN BEARING - UPPER

5 – CYLINDER BLOCK

6 – MAIN CAP BOLT - HORIZONTAL

7 – CRANKSHAFT THRUST WASHER

8 – CRANKSHAFT

LH 3.2/3.5L ENGINE 9 - 77

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...