DIAGNOSIS AND TESTING

ENGINE DIAGNOSIS—INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service Diagnosis—Mechanical Chart

and the Service Diagnosis—Performance Chart, for

possible causes and corrections of malfunctions. Refer

to FUEL SYSTEM for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

• Cylinder Compression Pressure Test

• Cylinder Combustion Pressure Leakage Test

• Cylinder Head Gasket Failure Diagnosis

• Intake Manifold Leakage Diagnosis

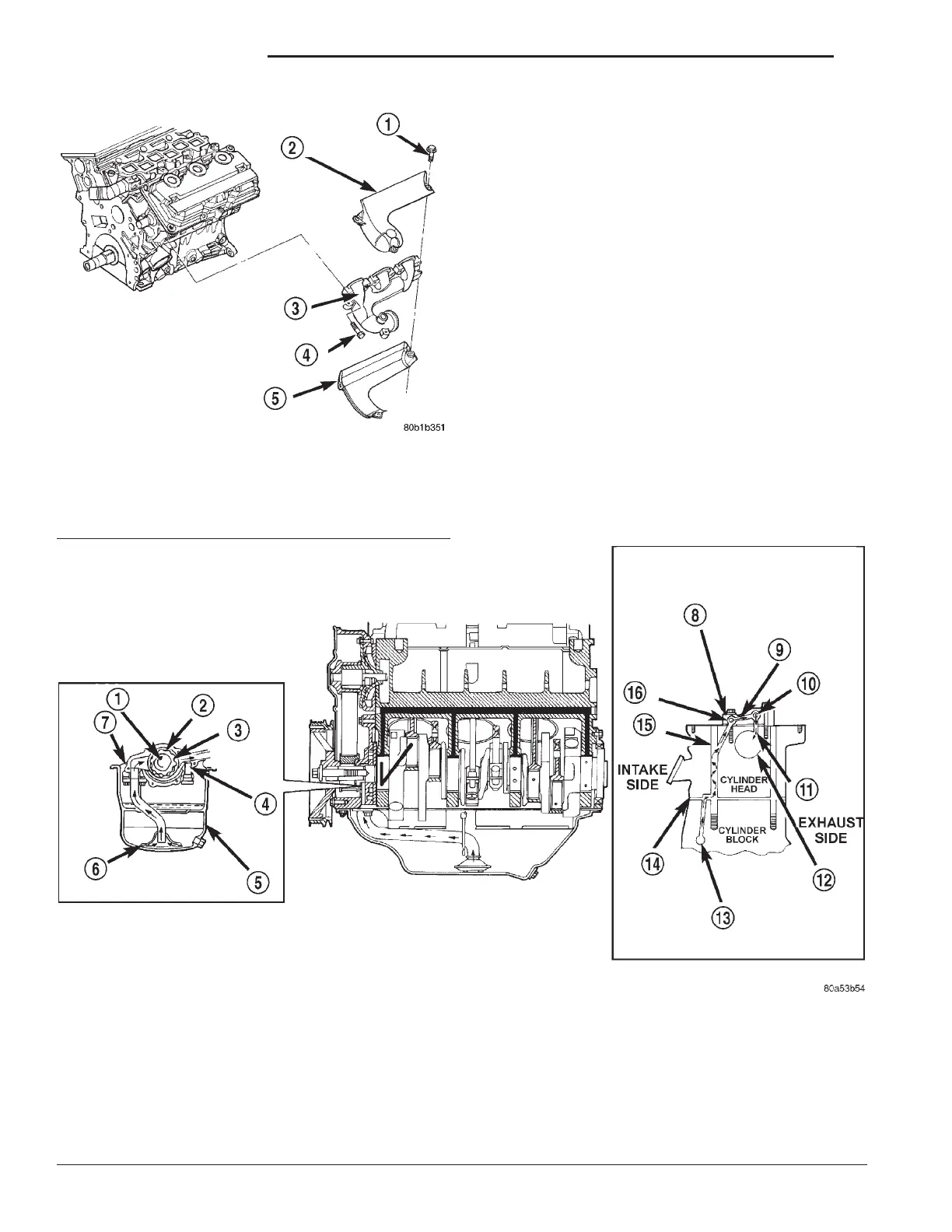

Fig. 10 Exhaust Manifold

1 – BOLT

2 – HEAT SHIELD

3 – EXHAUST MANIFOLD

4 – BOLT

5 – HEAT SHIELD

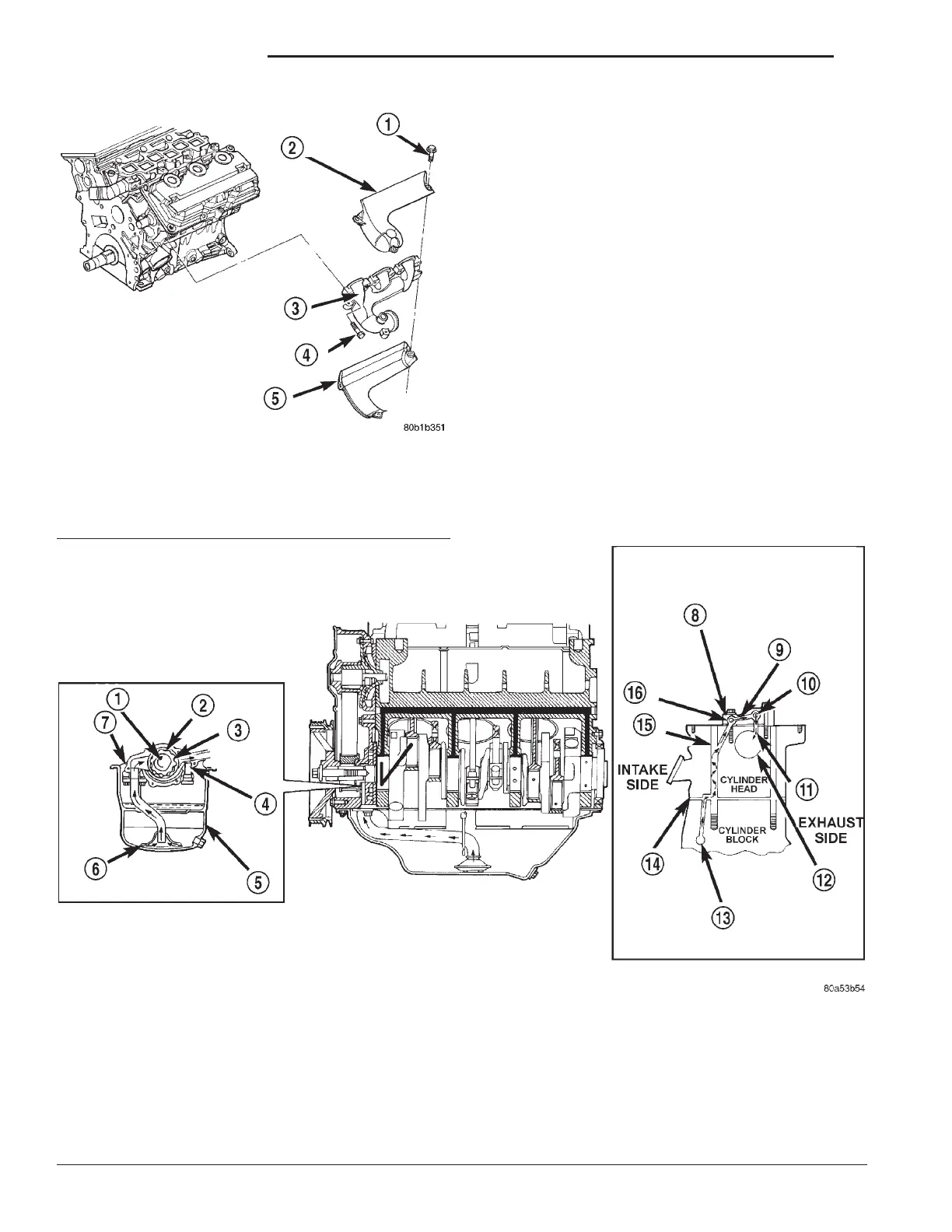

Fig. 11 Oil Lubrication System

1 – CRANKSHAFT

2 – OUTER ROTOR

3 – INNER ROTOR

4 – RELIEF VALVE

5 – OIL PAN

6 – OIL SCREEN

7 – OIL PUMP CASE

8 – OIL FLOWS TO ONLY ONE PEDESTAL AN EACH HEAD.

SECOND FROM REAR ON RIGHT HEAD AND SECOND

FROM FRONT ON LEFT HEAD.

9 – PEDESTAL DRILLED PASSAGE

10 – EXHAUST ROCKER SHAFT

11 – SHAFT/PEDESTAL DOWEL PASSAGE

12 – CAMSHAFT BEARING BORE

13 – CYLINDER BLOCK OIL GALLERY

14 – CYLINDER HEAD GASKET

15 – HEAD BOLT HOLE

16 – INTAKE ROCKER SHAFT

9 - 82 3.2/3.5L ENGINE LH

DESCRIPTION AND OPERATION (Continued)

Loading...

Loading...