HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

LASH ADJUSTER—BLEEDING

Use this procedure to manually bleed aerated oil

from the lash adjuster and remove sponginess.

(1) Run the engine, bringing it to operating tem-

perature in order to freshly pressurize and warm the

valvetrain system oil supply.

(2) Remove cylinder head cover(s).

(3) Ensure the rocker arm is positioned on the

base circle of the cam (Fig. 19). Rotate engine as nec-

essary.

(4) For intake rocker arm positions:

(a) Adjust Special Tool 8351 Release Probe’s

gauge pin to extend approximately 20 mm (0.787

in.). Then, carefully insert the release probe gauge

pin into the lash adjuster service access hole (Fig.

20).

CAUTION: If probe tip breaks off within the lash

adjuster, replace the affected rocker arm.

(b) Gently unseat lash adjuster’s internal check

ball.

(c) While the internal check ball is held

unseated, press the rocker arm into the valve tip,

allowing the lash adjuster to fully collapse. Hold

this fully collapsed position for about one second,

or longer.

(d) Slowly release the rocker arm, thereby

allowing the lash adjuster to extend, which in turn

refills the high pressure chamber with non-aerated

oil.

(e) Remove probe to allow check ball to seat.

(f) Recheck for sponginess. If the lash adjuster

sponginess is not completely or nearly eliminated,

then repeat procedure.

(g) If the spongy condition cannot be removed,

replace effected rocker arm(s).

(5) For exhaust rocker arm positions:

(a) Adjust Special Tool 8351 Release Probe’s

gauge pin to extend approximately 20 mm (0.787

in.). Then, using two release probes, carefully

insert gauge pins into the lash adjuster service

access holes (Fig. 20).

CAUTION: If probe tip breaks off within the lash

adjuster, replace the affected rocker arm.

(b) Gently unseat BOTH lash adjuster’s internal

check ball at the same time.

(c) While the internal check ball is held

unseated, press the rocker arm into the valve tip,

allowing the lash adjuster to fully collapse. Hold

this fully collapsed position for about one second,

or longer.

(d) Slowly release the rocker arm, thereby allow-

ing the lash adjuster to extend, which in turn

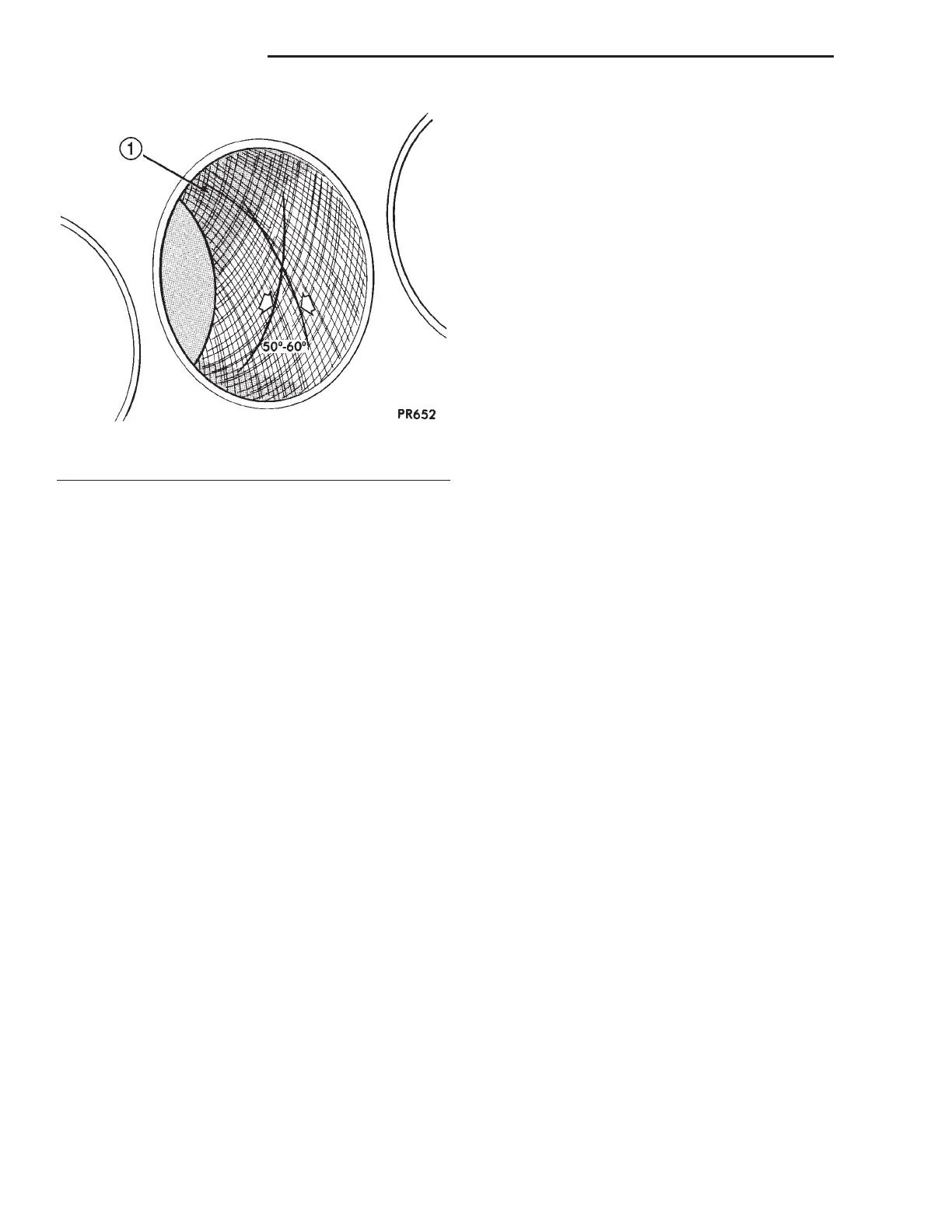

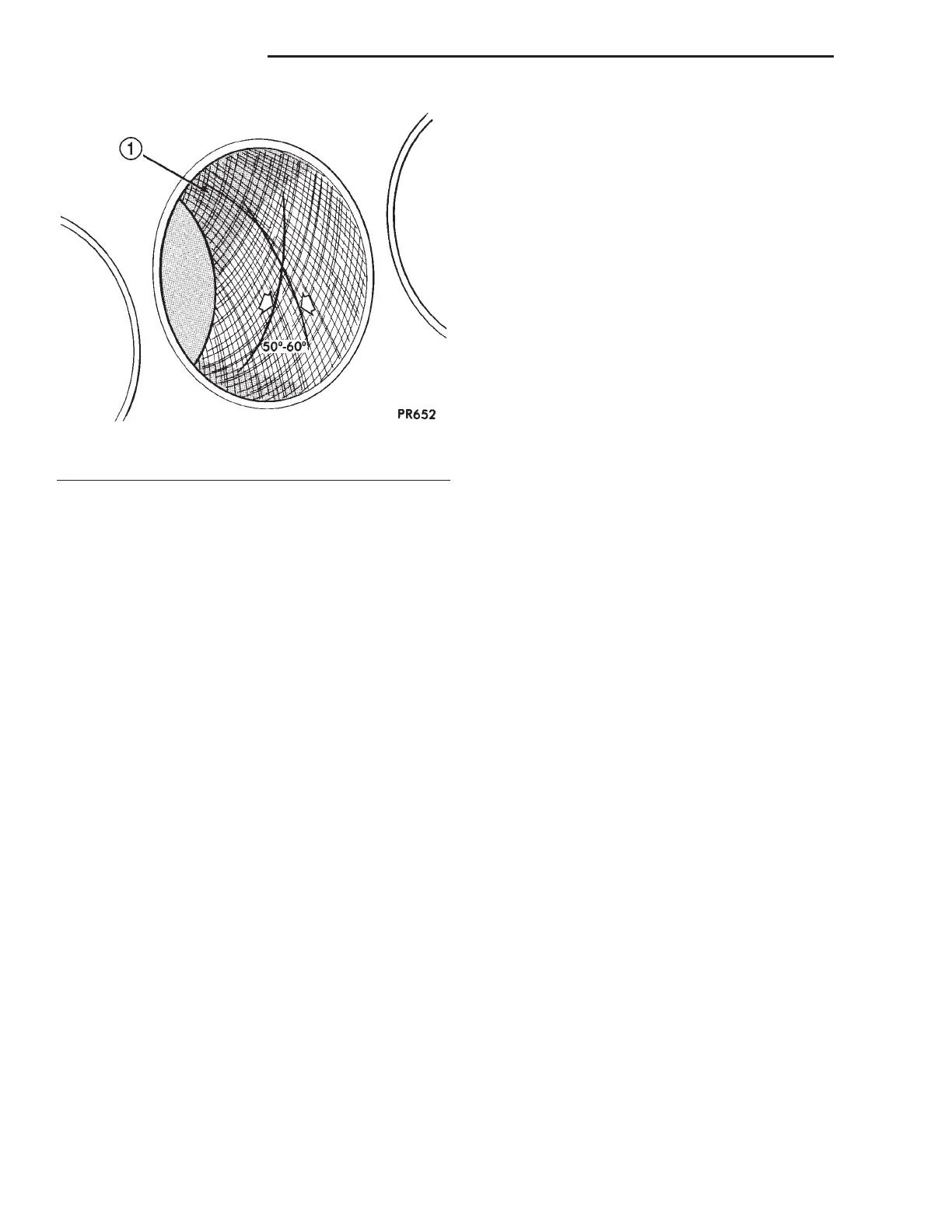

Fig. 18 Cylinder Bore Cross-Hatch Pattern

1 – CROSS-HATCH PATTERN

9 - 94 3.2/3.5L ENGINE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...