CYLINDER BLOCK AND BORE

CLEANING AND INSPECTION

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, Refer to Engine

Core Plugs.

(3) Examine block for cracks or fractures.

(4) Inspect for damaged bolt threads. Repair

threads as needed. Refer to Service Procedures,

Repair of Damaged or Worn Threads.

NOTE: Refer to Honing Cylinder Bores outlined in

the Standard Service Procedures for specification

and procedures.

(5) After a cylinder bore honing or deglazing pro-

cedure:

(a) Clean bores with a soap and water solution.

(b) Thoroughly rinse cylinder bores with clean

water to remove soap/water solution and wipe

bores with a clean lint-free cloth.

(c) Oil the bores after cleaning to prevent rust.

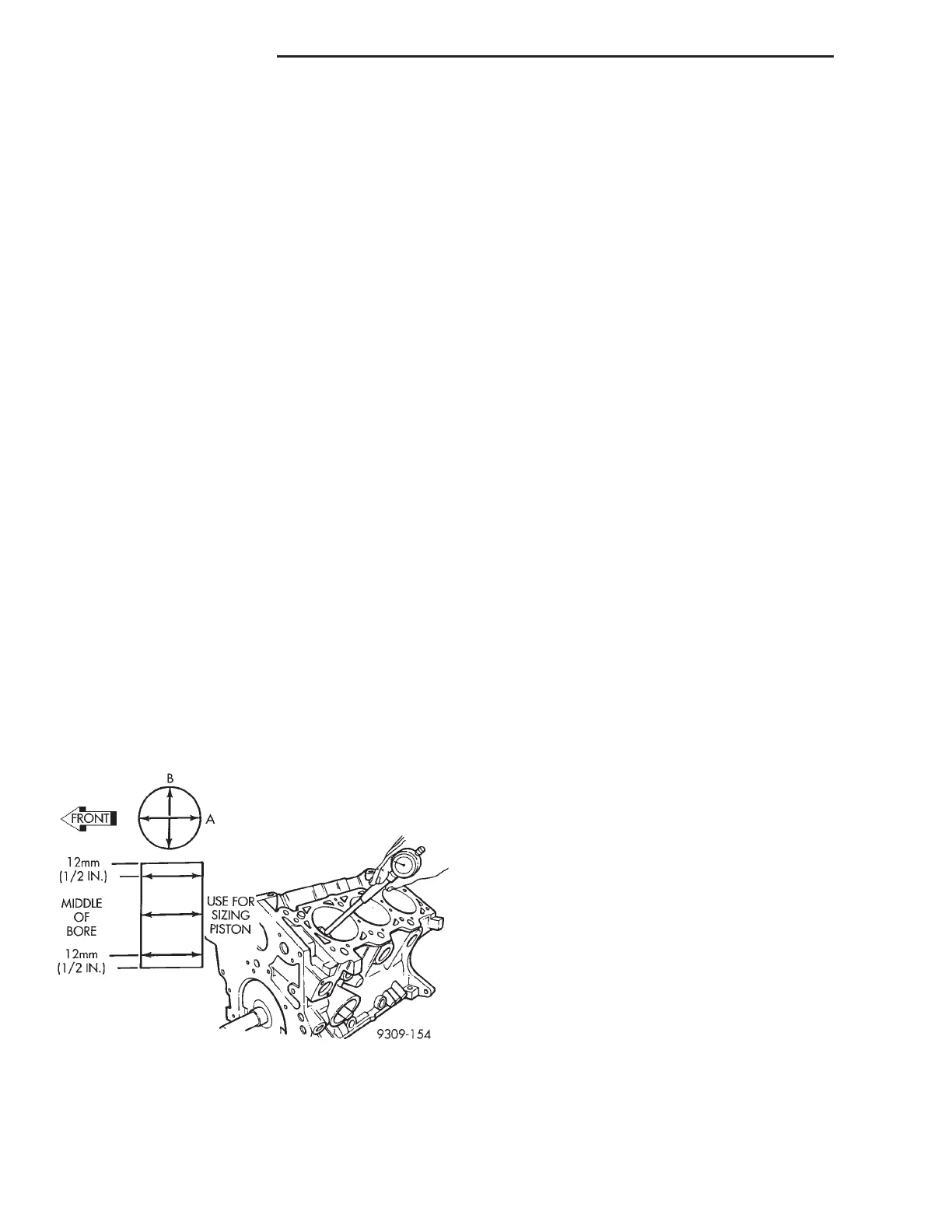

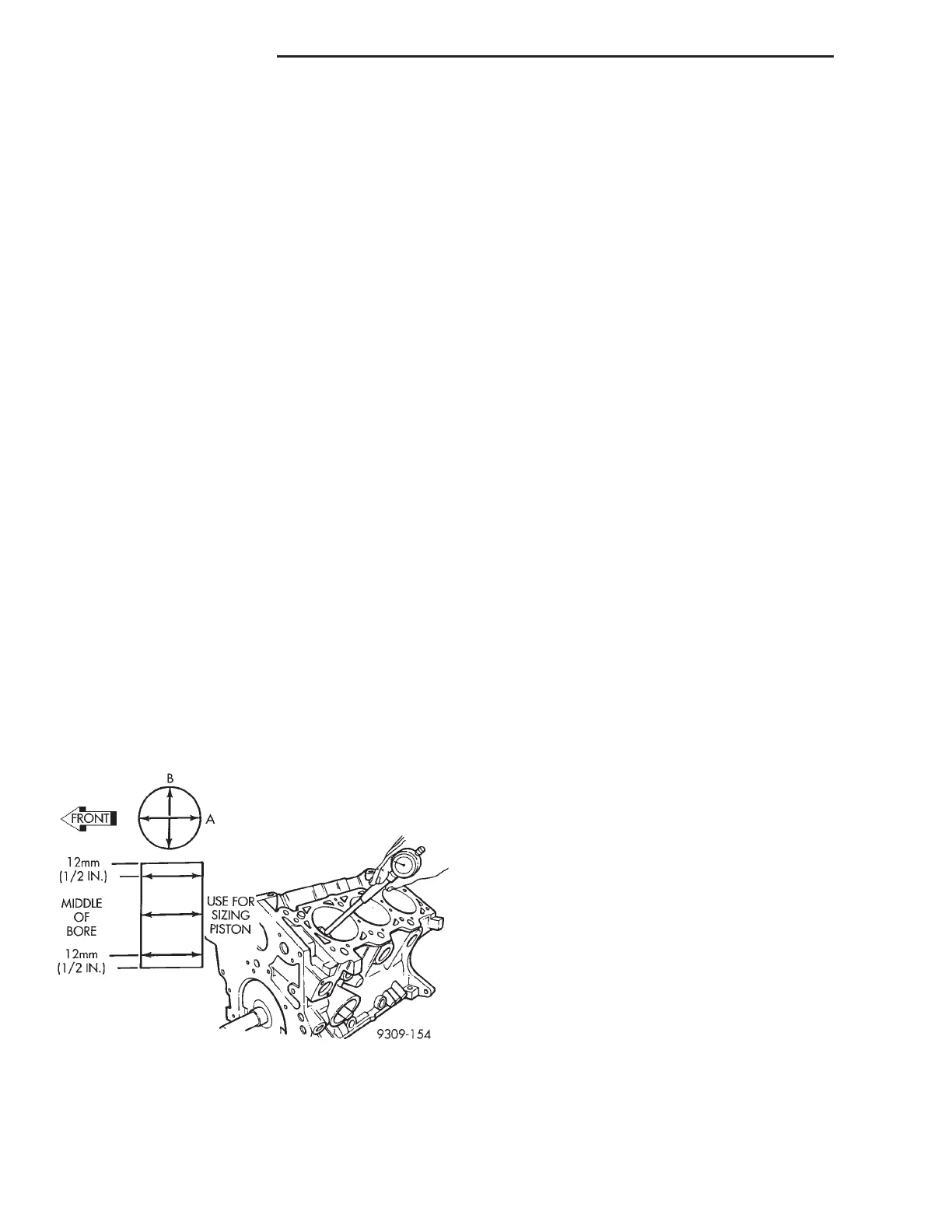

CYLINDER BORE INSPECTION

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 146).

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 146). Top measurement should be

12 mm (0.50 inch.) down and bottom measurement

should be 12 mm (0.50 inch.) up from bottom of bore.

Refer to Engine Specifications.

NOTE: There are no service procedures to bore the

cylinder bores for installation of oversized pistons.

ENGINE HYDRO-MOUNT INSULATORS

Engine hydro-mounts may show surface cracks this

will not effect performance and mount should not be

replaced. Only replace the engine hydro-mounts

when leaking fluid:

• Drive shaft distress: Refer to Driveshafts in Sus-

pension, Group 2.

• Any front end structural damage (after repair).

• Insulator replacement.

TIMING BELT INSPECTION—IN VEHICLE

(1) Remove the accessory drive belts. Refer to

COOLING SYSTEM for procedure.

(2) Remove timing belt covers. Refer to procedure

in this section.

(3) Inspect both sides of the timing belt. Replace

belt if any of the following conditions exist (Fig. 147):

(a) Hardening of back rubber back side is glossy

without resilience and leaves no indent when

pressed with fingernail.

(b) Cracks on rubber back.

(c) Cracks or peeling of canvas.

(d) Cracks on rib root.

(e) Cracks on belt sides.

(f) Missing teeth.

(g) Abnormal wear of belt sides. The sides are

normal if they are sharp as if cut by a knife.

(h) Vehicle mileage at component maintenance

requirement. Refer to LUBRICATION AND MAIN-

TENANCE.

(4) If none of the above conditions are seen on the

belt, the belt cover can be installed.

NOTE: If belt requires replacing, ensure the proper

length belt is used.

Fig. 146 Checking Cylinder Bore Size

9 - 142 3.2/3.5L ENGINE LH

CLEANING AND INSPECTION (Continued)

Loading...

Loading...