INSTALLATION

(1) Install the lower control arm and tension strut

on the cradle using the following sequence. Install

tension strut and isolator bushing into cradle first,

then install lower control arm pivot bushing into

bracket on cradle (Fig. 41).

(2) Install the lower control arm to cradle bracket

attaching pivot bolt and nut (Fig. 40). Do not

tighten the lower control arm to cradle bracket

attaching bolt at this time.

(3) Install washer on end of tension strut (Fig. 39).

Install a NEW tension strut to cradle bracket nut, on

tension strut (Fig. 39). Tighten the tension strut to

cradle bracket retaining nut to a torque of 130 N·m

(95 ft. lbs.). When torquing tension strut nut, keep

tension strut from turning by holding tension strut

at flat using an open end wrench (Fig. 39).

CAUTION: Pulling steering knuckle out from vehi-

cle after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

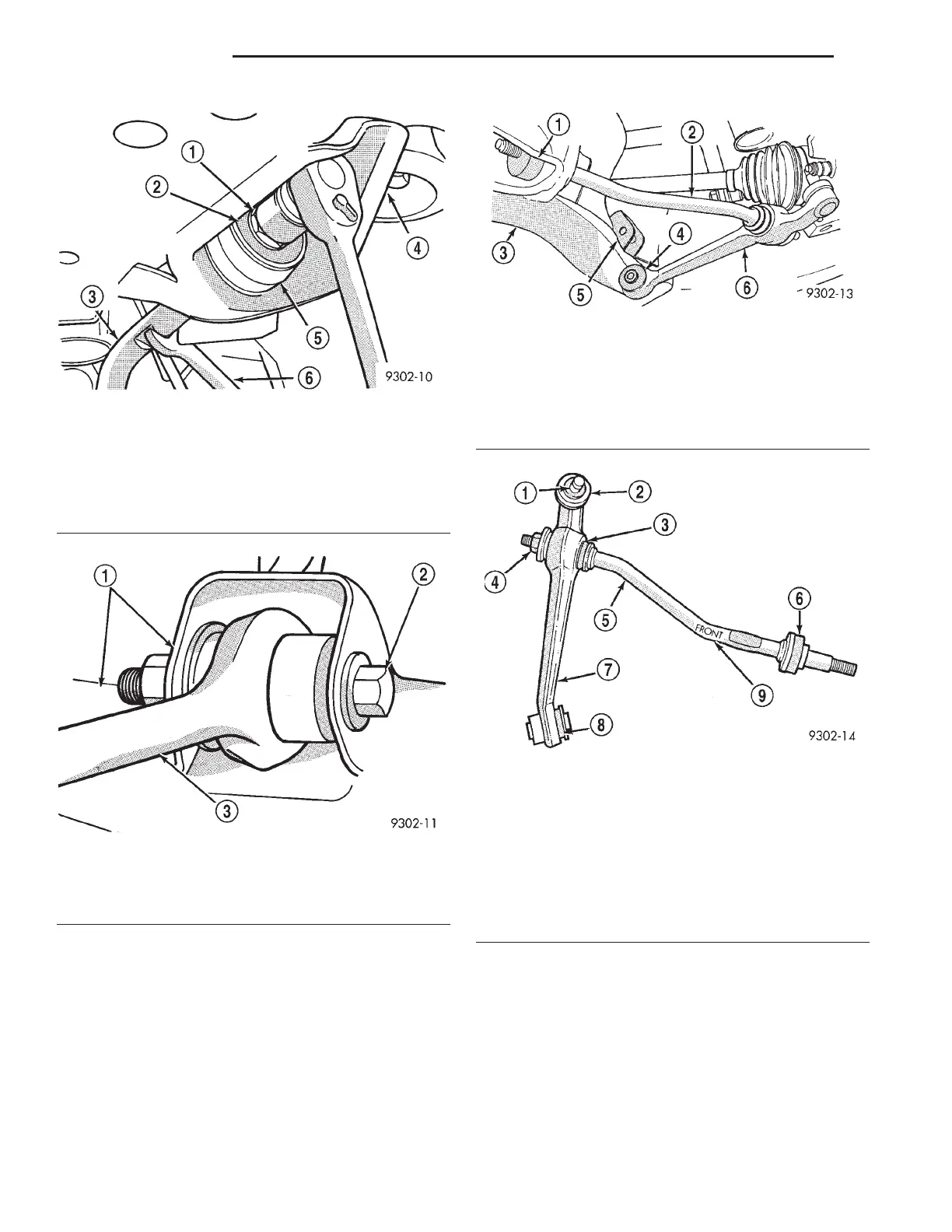

Fig. 39 Tension Strut To Cradle Mounting

1 – NUT

2 – WASHER

3 – TENSION STRUT

4 – CRADLE ASSEMBLY

5 – ISOLATOR BUSHING

6 – FLAT

Fig. 40 Lower Control Arm Pivot Bolt

1 – CRADLE ASSEMBLY

2 – PIVOT BOLT

3 – LOWER CONTROL ARM

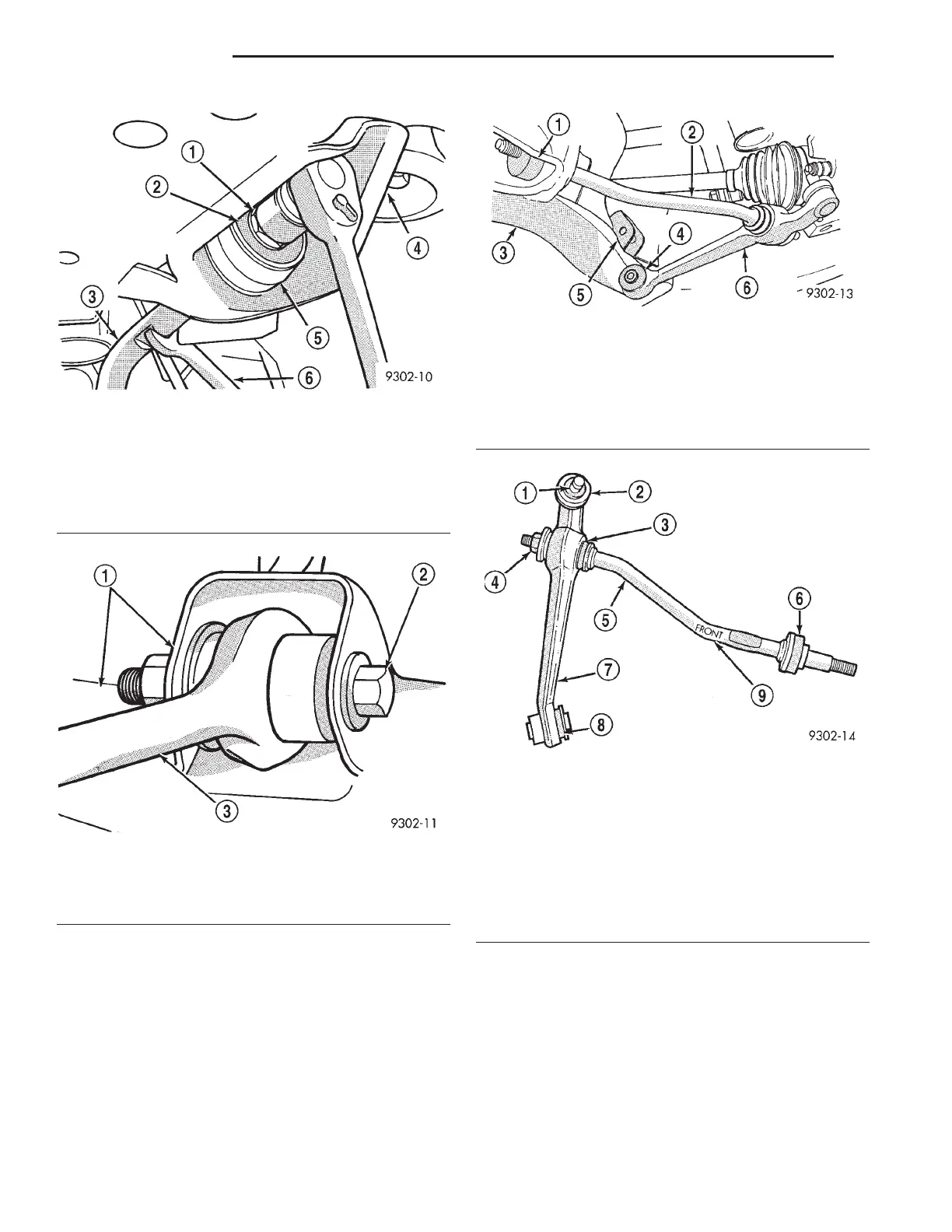

Fig. 41 Lower Control Arm Remove/Install

1 – ISOLATOR BUSHING

2 – TENSION STRUT

3 – CRADLE

4 – PIVOT BUSHING

5 – LOWER CONTROL ARM BRACKET

6 – LOWER CONTROL ARM

Fig. 42 Lower Control Arm And Tension Strut

1 – BALL JOINT STUD

2 – BALL JOINT SEAL

3 – LOWER CONTROL ARM TENSION STRUT BUSHING

4 – NUT

5 – TENSION STRUT

6 – TENSION STRUT TO CRADLE ISOLATOR BUSHING

7 – LOWER CONTROL ARM

8 – LOWER CONTROL ARM PIVOT BUSHING

9 – WORD “FRONT” STAMPED IN CONTROL ARM HERE

2 - 26 SUSPENSION LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...