(7) Rotate crankshaft so that the connecting rod

journal is on the center of the cylinder bore. Insert

rod and piston into cylinder bore and guide rod over

the crankshaft journal (Fig. 101).

CAUTION: Do Not interchange piston assemblies

bank to bank, as engine damage may occur.

(8) Tap the piston down in cylinder bore, using a

hammer handle. At the same time, guide connecting

rod into position on connecting rod journal.

(9) Lubricate rod bolts and bearing surface with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 N·m (20 ft. lbs.) Plus 1/4 turn.

ENGINE CORE AND OIL PLUGS

REMOVAL

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 103).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

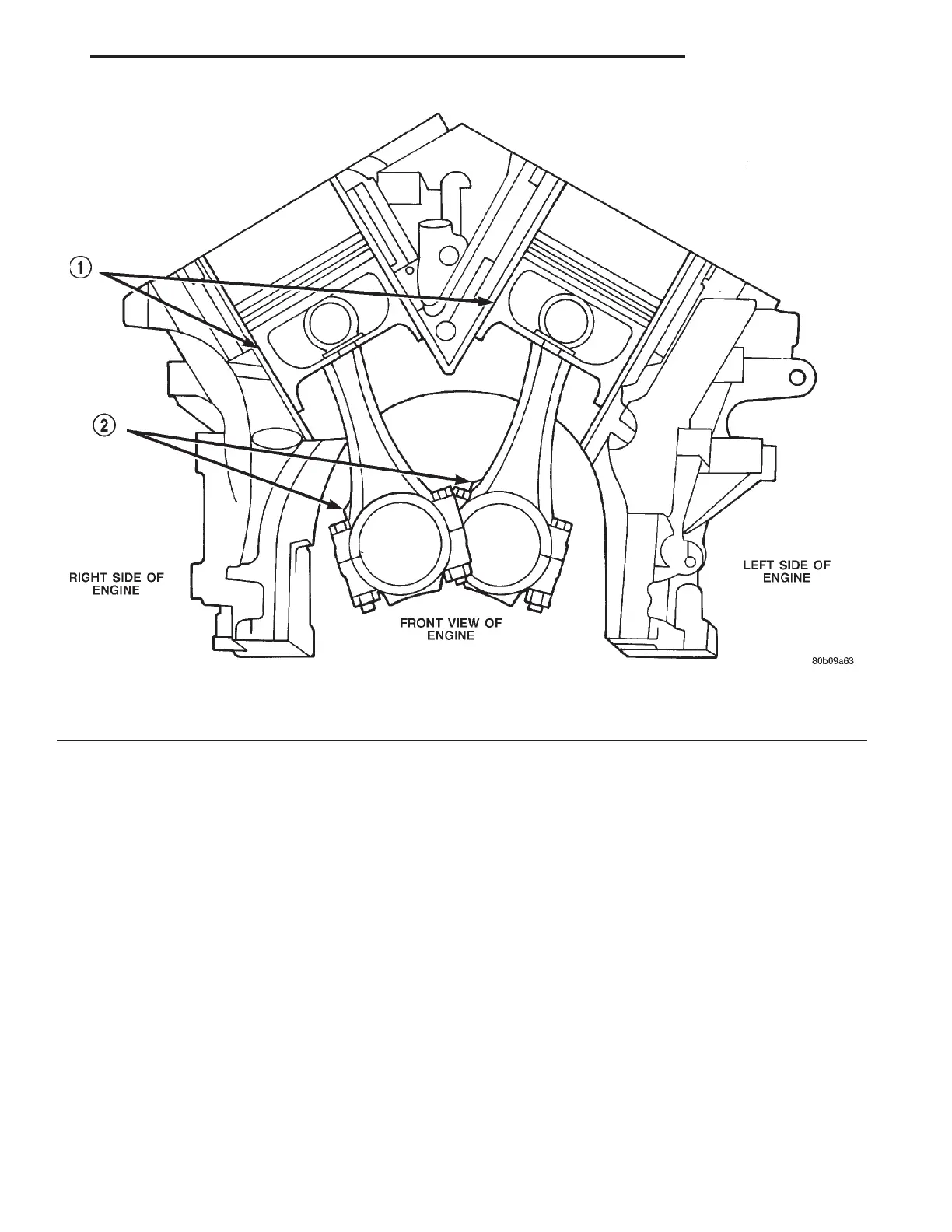

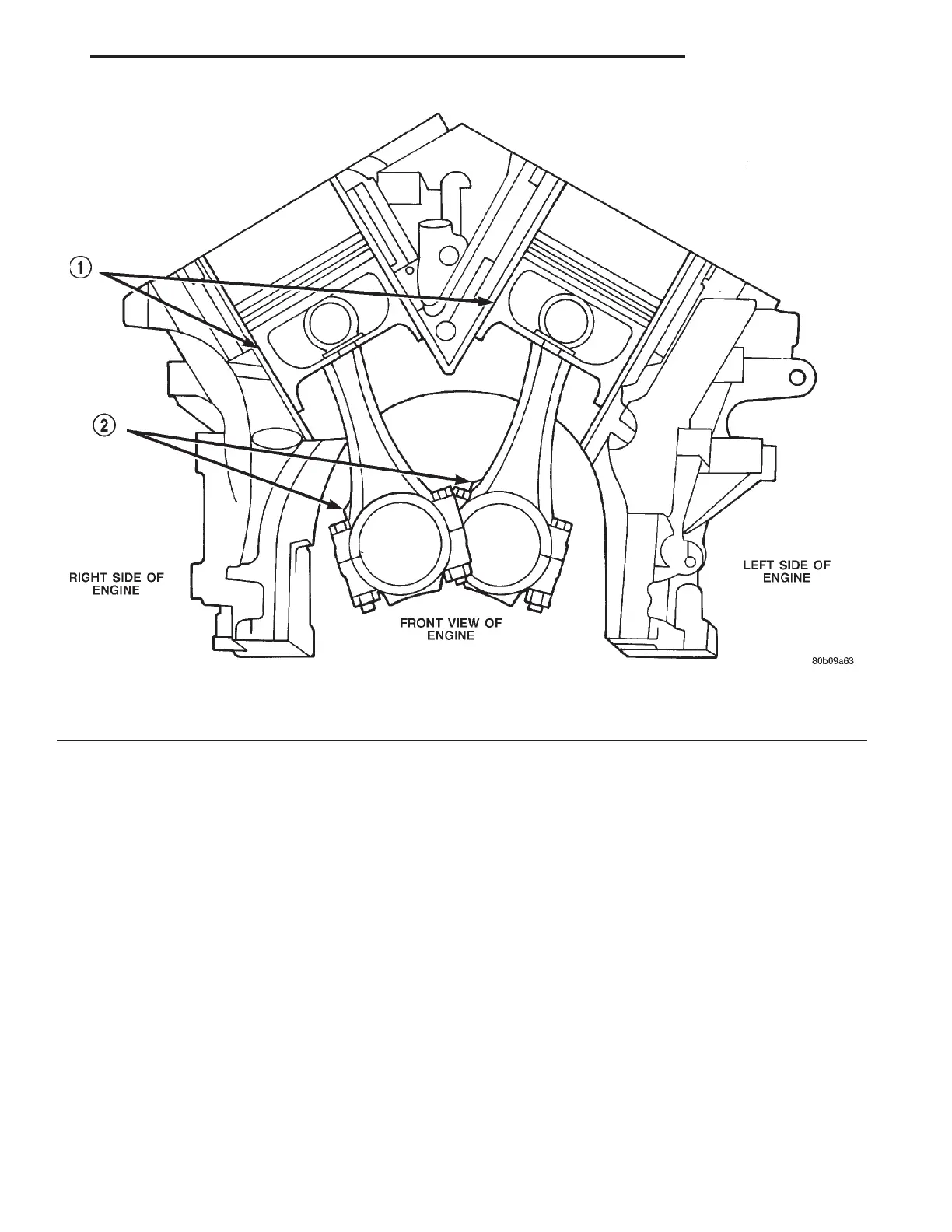

Fig. 102 Piston and Connecting Rod Positioning

1 – MAJOR THRUST SIDE OF PISTON

2 – OIL SQUIRT HOLE

LH 2.7L ENGINE 9 - 61

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...