CLEANING AND INSPECTION

INTAKE MANIFOLD

Check for:

• Damage and cracks of each section.

• Clogged water passages in end cross over and

clogged gas passages.

EXHAUST MANIFOLD

Inspect exhaust manifolds for damage or cracks

and check distortion of the cylinder head mounting

surface with a straightedge and thickness gauge.

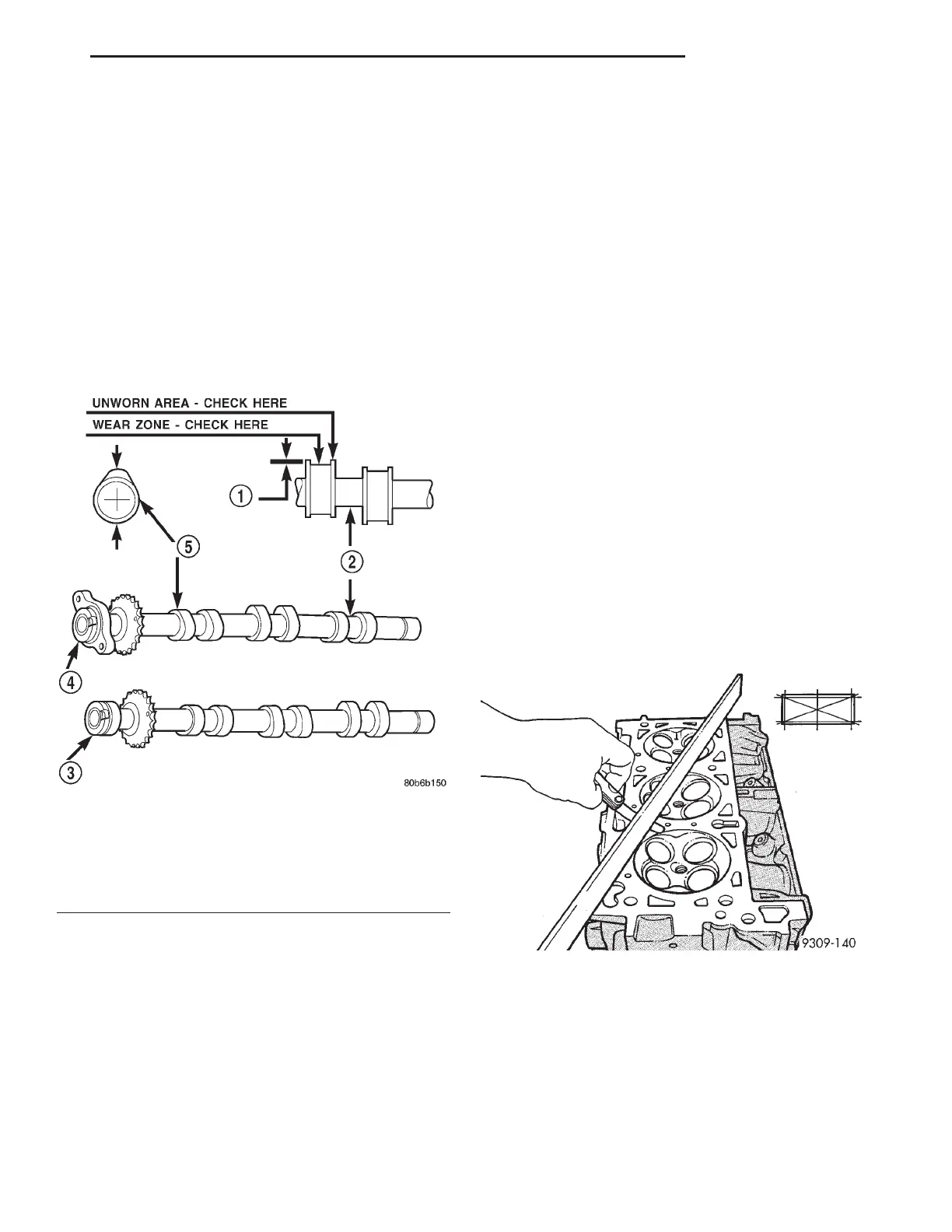

CAMSHAFT

(1) Inspect camshaft bearing journals for damage

and binding (Fig. 106). If journals are binding, check

the cylinder head for damage. Also check cylinder

head oil holes for clogging.

(2) Inspect camshaft sprockets for excessive wear.

Replace camshafts if necessary.

(3) Check the cam lobe surfaces for abnormal wear

and damage. Replace camshaft if defective. Measure

the actual wear (Fig. 106) and replace, if out of lim-

its—standard value is 0.0254 mm (0.001 in.); wear

limit is 0.254 mm (0.010 in.).

CYLINDER HEAD

CLEANING

(1) Use a gasket removal compound to soften the

old gasket material.

CAUTION: When cleaning the cylinder head and

block mating surfaces, do not use a metal scraper

because the sealing surfaces could be cut or

ground. Instead, use a wooden or plastic scraper.

(2) Make sure the gasket and/or foreign material

does not enter the oil feed hole or the oil return

holes.

INSPECTION

(1) Before cleaning, check for leaks, damage and

cracks.

(2) Clean cylinder head and oil passages.

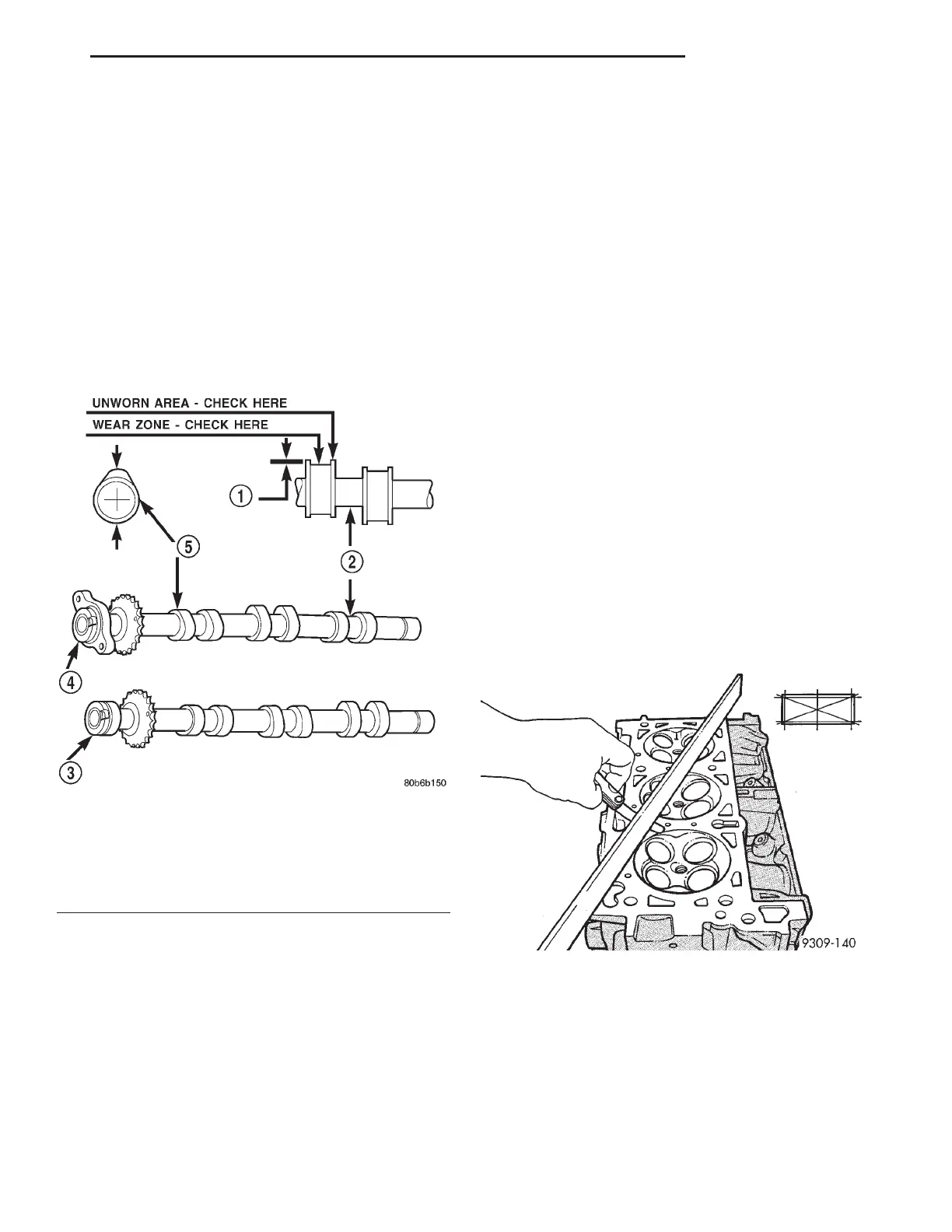

(3) Check cylinder head for flatness (Fig. 107).

(4) Cylinder head must be flat within:

• Standard dimension = less than 0.05 mm (0.002

inch.)

• Service Limit = 0.2 mm (0.008 inch.)

• Grinding Limit = Maximum of 0.2 mm (0.008

inch.) is permitted.

CAUTION: 0.20 mm (0.008 in.) MAX is a combined

total dimension of the stock removal limit from cyl-

inder head and block top surface (Deck) together.

CAMSHAFT FOLLOWER

Inspect the cam follower assembly for wear or

damage (Fig. 108). Replace as necessary.

VALVE INSPECTION

(1) Clean valves thoroughly and replace burned,

warped and cracked valves.

(2) Measure valve stems for wear (Fig. 109). Refer

to Engine Specifications.

Fig. 106 Camshaft Inspection

1 – ACTUAL WEAR

2 – BEARING JOURNAL

3 – EXHAUST CAMSHAFT

4 – INTAKE CAMSHAFT

5 – LOBE

Fig. 107 Checking Cylinder Head Flatness—Typical

LH 2.7L ENGINE 9 - 63

Loading...

Loading...