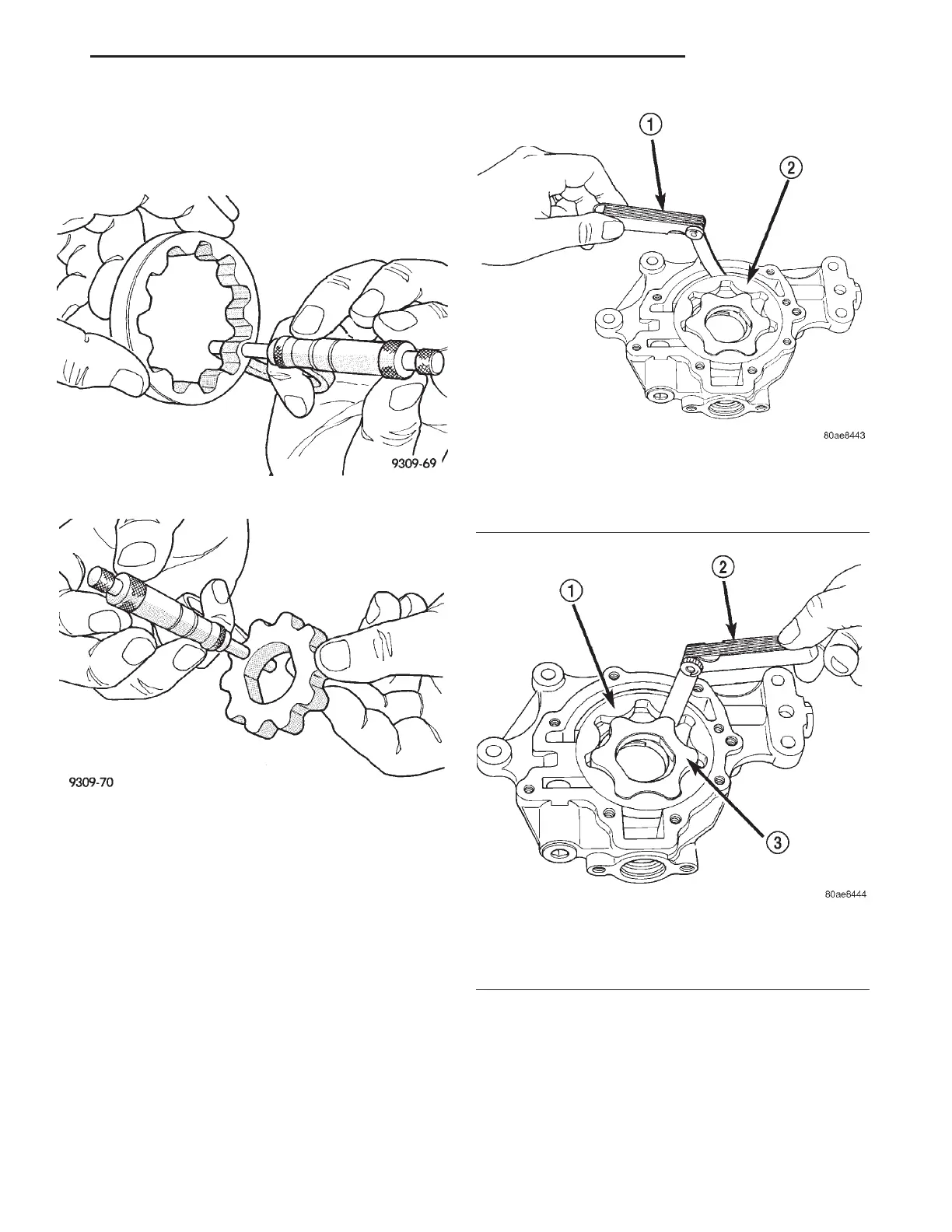

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 9.474 mm (0.373

in.) or less (Fig. 112), or if the diameter is 89.174 mm

(3.5108 inches.) or less, replace outer rotor.

(4) If inner rotor measures 9.474 mm (0.373 inch.)

or less replace inner rotor (Fig. 113).

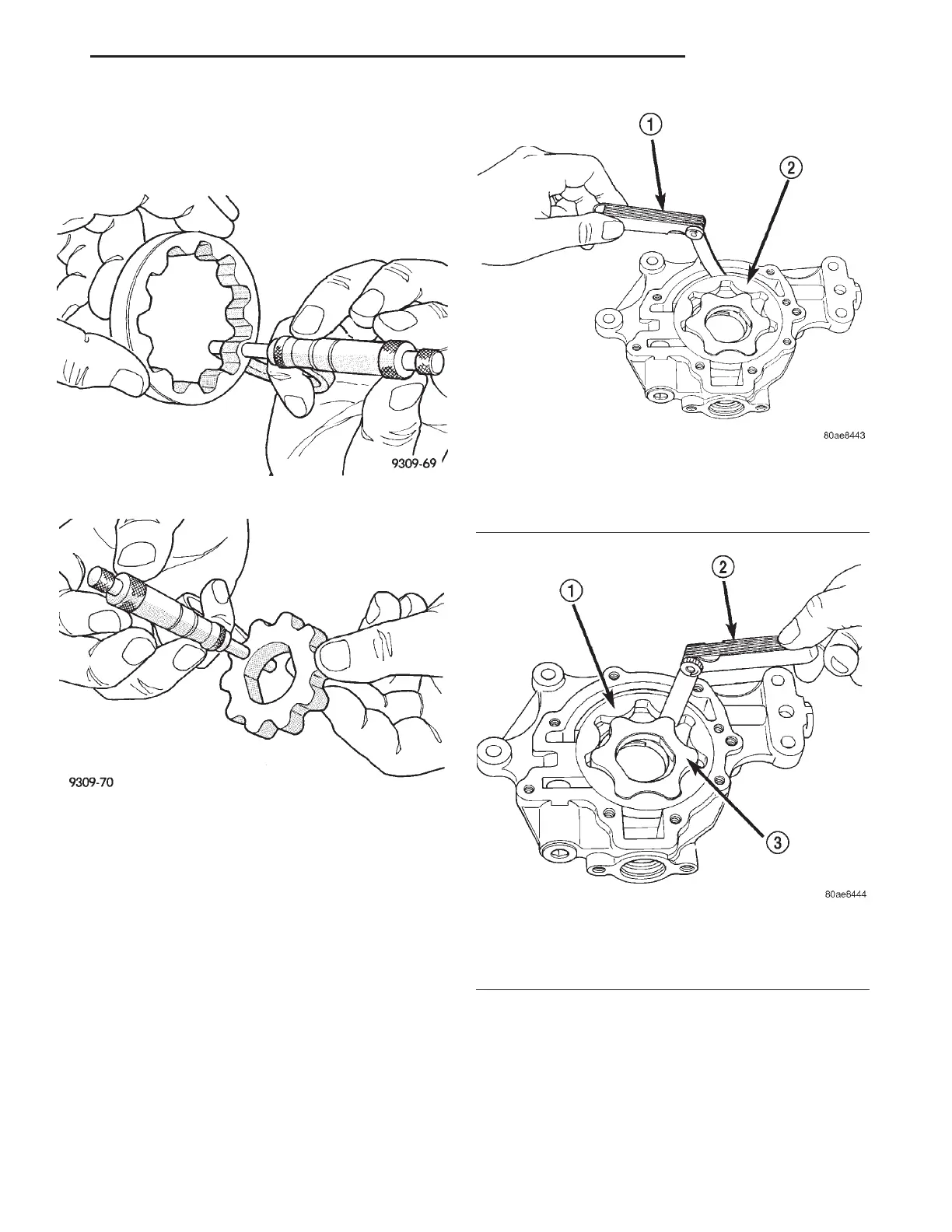

(5) Slide outer rotor into body, press to one side

with fingers and measure clearance between rotor

and body (Fig. 114). If measurement is 0.39 mm

(0.015 inch.) or more, replace body only if outer rotor

is in specifications.

(6) Install inner rotor into body. If clearance

between inner and outer rotors (Fig. 115) is 0.20 mm

(0.008 inch.) or more, replace both rotors.

(7) Place a straightedge across the face of the body,

between bolt holes. If a feeler gauge of 0.077 mm

(0.003 inch.) or more can be inserted between rotors

and the straightedge, replace pump assembly (Fig.

116) ONLY if rotors are in specs.

(8) Inspect oil pressure relief valve plunger for

scoring and free operation in its bore. Small marks

may be removed with 400-grit wet or dry sandpaper.

(9) The relief valve spring has a free length of

approximately 49.5 mm (1.95 inches) it should test

between 23 – 25 pounds when compressed to 34 mm

(1.34 in.). Replace spring that fails to meet specifica-

tions.

Fig. 112 Measuring Outer Rotor Thickness

Fig. 113 Measuring Inner Rotor Thickness

Fig. 114 Measuring Outer Rotor Clearance in

Housing

1 – FEELER GAUGE

2 – OUTER ROTOR

Fig. 115 Measuring Clearance Between Rotors

1 – OUTER ROTOR

2 – FEELER GAUGE

3 – INNER ROTOR

LH 2.7L ENGINE 9 - 65

CLEANING AND INSPECTION (Continued)

Loading...

Loading...