OIL PUMP ASSEMBLY

(1) Assemble pump, using new parts as required.

(2) Tighten cover screws to 12 N·m (105 in. lbs.).

(3) Prime oil pump before installation by filling

rotor cavity with engine oil.

(4) If oil pressure is low and pump is within spec-

ifications, inspect for worn engine bearings or other

reasons for oil pressure loss.

CYLINDER BLOCK AND BORE

CLEANING AND INSPECTION

(1) Clean cylinder block thoroughly and check all

core hole plugs for evidence of leaking.

(2) If new core plugs are installed, refer to Service

Procedures, Engine Core Plugs.

(3) Examine block for cracks or fractures.

(4) Inspect for damaged bolt threads. Repair

threads as needed. Refer to Service Procedures,

Repair of Damaged or Worn Threads.

NOTE: Refer to Honing Cylinder Bores in the Stan-

dard Service Procedures for specification and pro-

cedures.

(5) After a cylinder honing or deglazing procedure:

(a) Clean bores with soap and water solution.

(b) Thoroughly rinse cylinder bores with clean

water to remove soap/water solution and wipe

bores dry with a clean lint-free cloth.

(c) Oil the bores after cleaning to prevent rust-

ing.

CYLINDER BORE INSPECTION

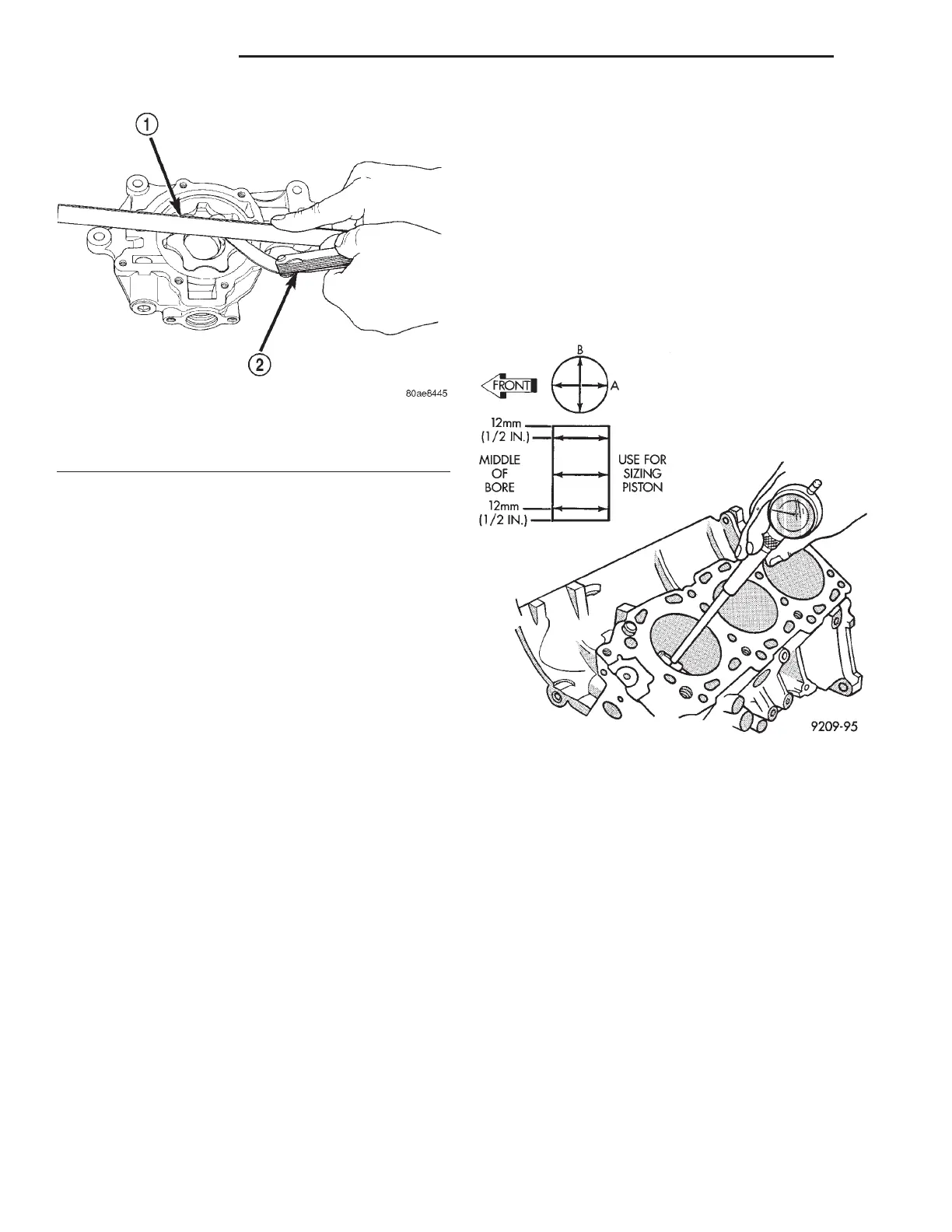

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 as shown in (Fig.

117).

Measure the cylinder bore at three levels in direc-

tions A and B (Fig. 117). Top measurement should be

12 mm (0.50 inch.) down and bottom measurement

should be 12 mm (0.50 inch.) up from bottom of bore.

Refer to Engine Specifications.

NOTE: There are no service procedures to bore the

cylinder bores for installation of oversized pistons.

ENGINE HYDRO-MOUNT ISOLATOR

Engine hydro-mounts may show surface cracks.

This will not effect performance and mount should

not be replaced. Only replace the engine hydro-

mounts when leaking fluid:

• Driveshaft diagnosis. Refer to DIFFERENTIAL

AND DRIVELINE.

• Any front end structural damage (after repair).

• Isolator replacement.

TIMING DRIVE SYSTEM

INSPECTION

For checking timing drive system wear limits, use

the following procedure.

(1) Remove right cylinder head cover.

(2) Viewing through the cylinder head timing drive

cavity, inspect the primary chain tensioner plunger.

Rotate the engine clockwise to remove any chain

slack and to achieve the maximum tensioner exten-

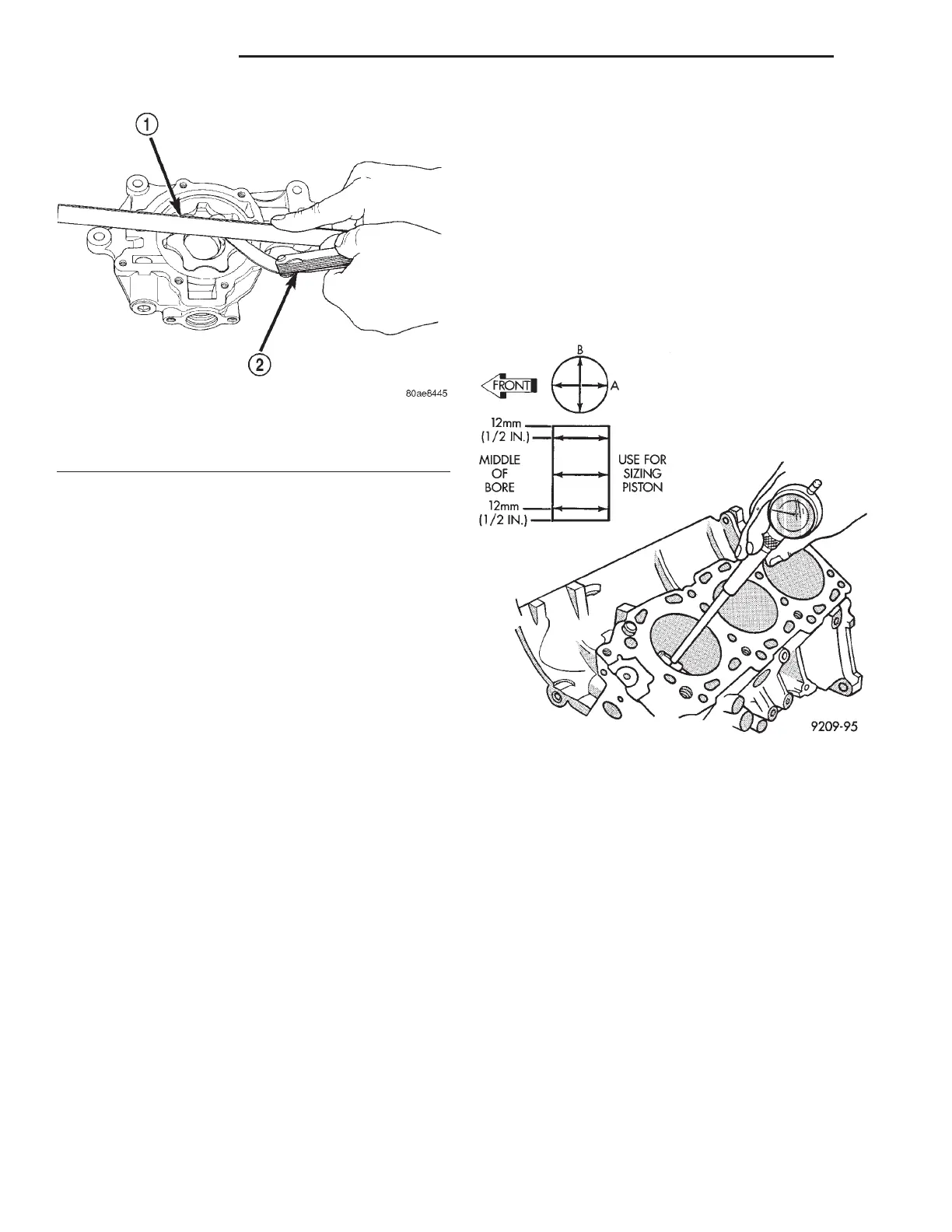

Fig. 116 Measuring Clearance Over Rotors

1 – STRAIGHT EDGE

2 – FEELER GAUGE

Fig. 117 Cylinder Bore Size Checking

9 - 66 2.7L ENGINE LH

CLEANING AND INSPECTION (Continued)

Loading...

Loading...