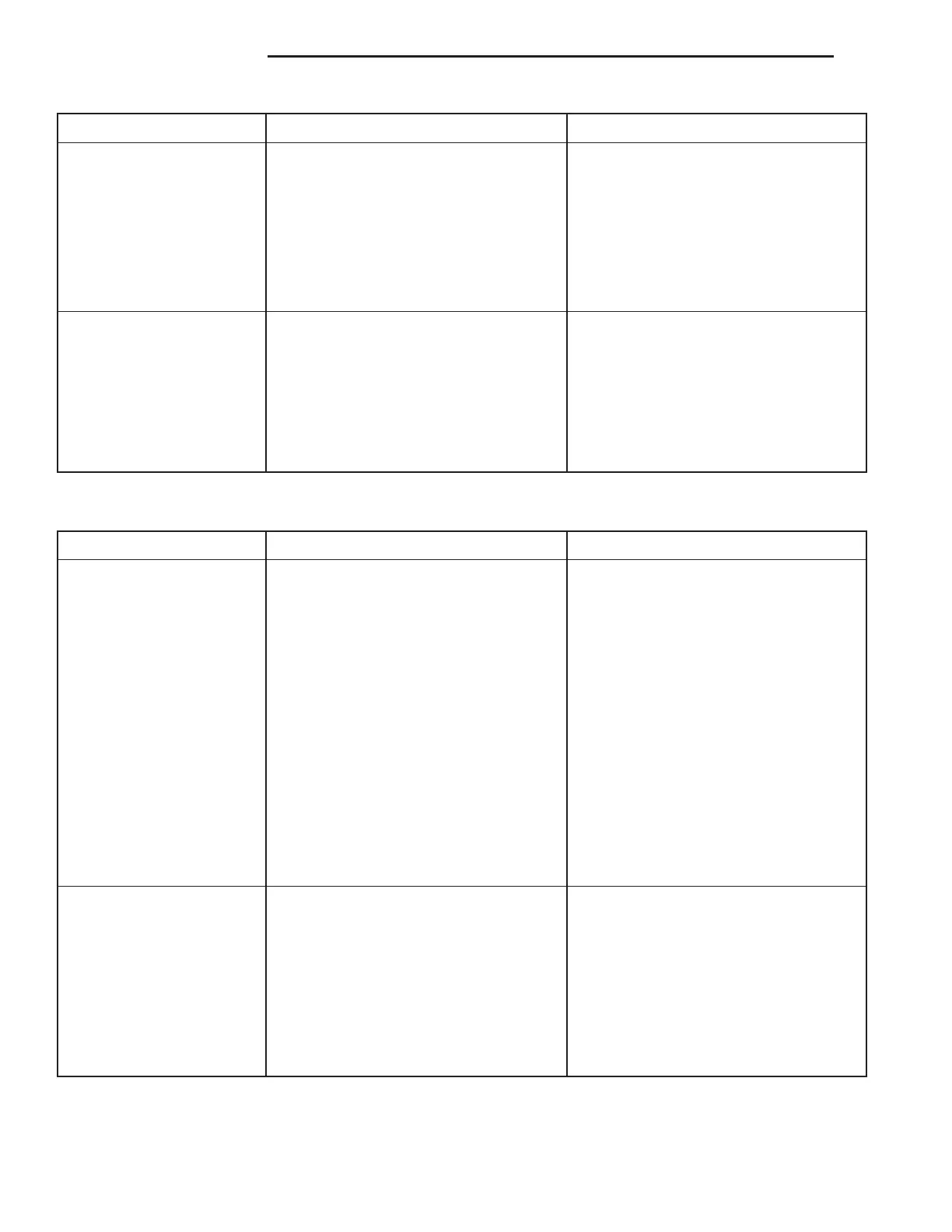

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE MISSES ON

ACCELERATION

1. Dirty or incorrectly gapped spark

plugs.

1. Clean spark plugs and set gap. Refer

to IGNITION SYSTEM.

2. Contamination in Fuel System. 2. Clean fuel system and replace fuel

filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty coil(s). 4. Test and replace as necessary. Refer

to IGNITION SYSTEM.

ENGINE MISSES AT HIGH

SPEED

1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap. Refer

to IGNITION SYSTEM.

2. Faulty coil(s). 2. Test and replace as necessary. Refer

to IGNITION SYSTEM.

3. Dirty fuel injector(s). Test and replace as necessary. Refer to

FUEL SYSTEM.

4. Contamination in fuel system. 4. Clean system and replace fuel filter.

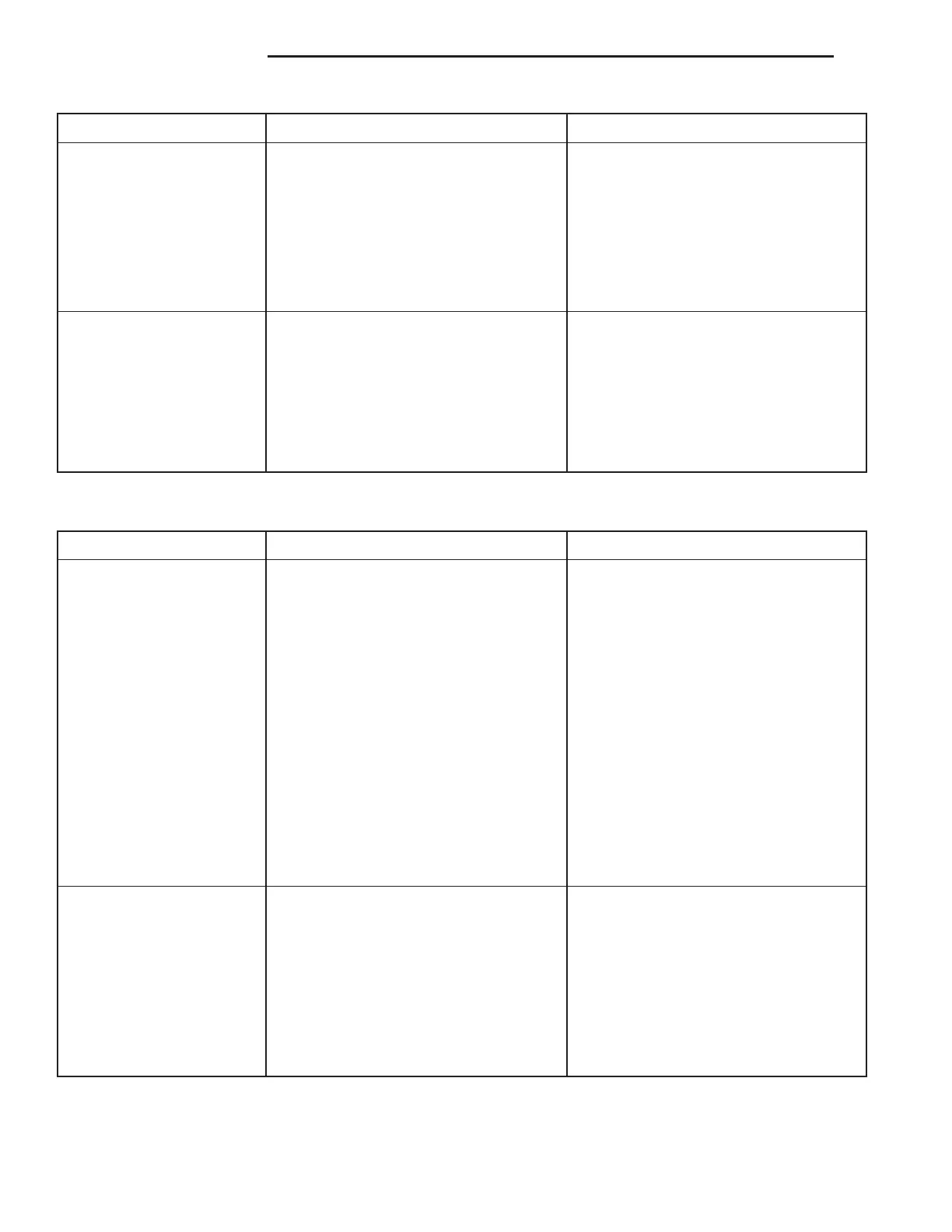

ENGINE DIAGNOSIS—MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in crankcase. 1. Check and correct engine oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check and correct engine oil level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic lash

adjuster assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic lash

adjuster assembly.

7. Worn valve guides. 7. Ream guides and install new valves

with oversize stems.

8. Excessive runout of valve seats on

valve faces.

8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic lash

adjuster assembly.

CONNECTING ROD

NOISE

1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Connecting rod journal out-of-round. 5. Replace crankshaft or grind surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 84 3.2/3.5L ENGINE LH

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...