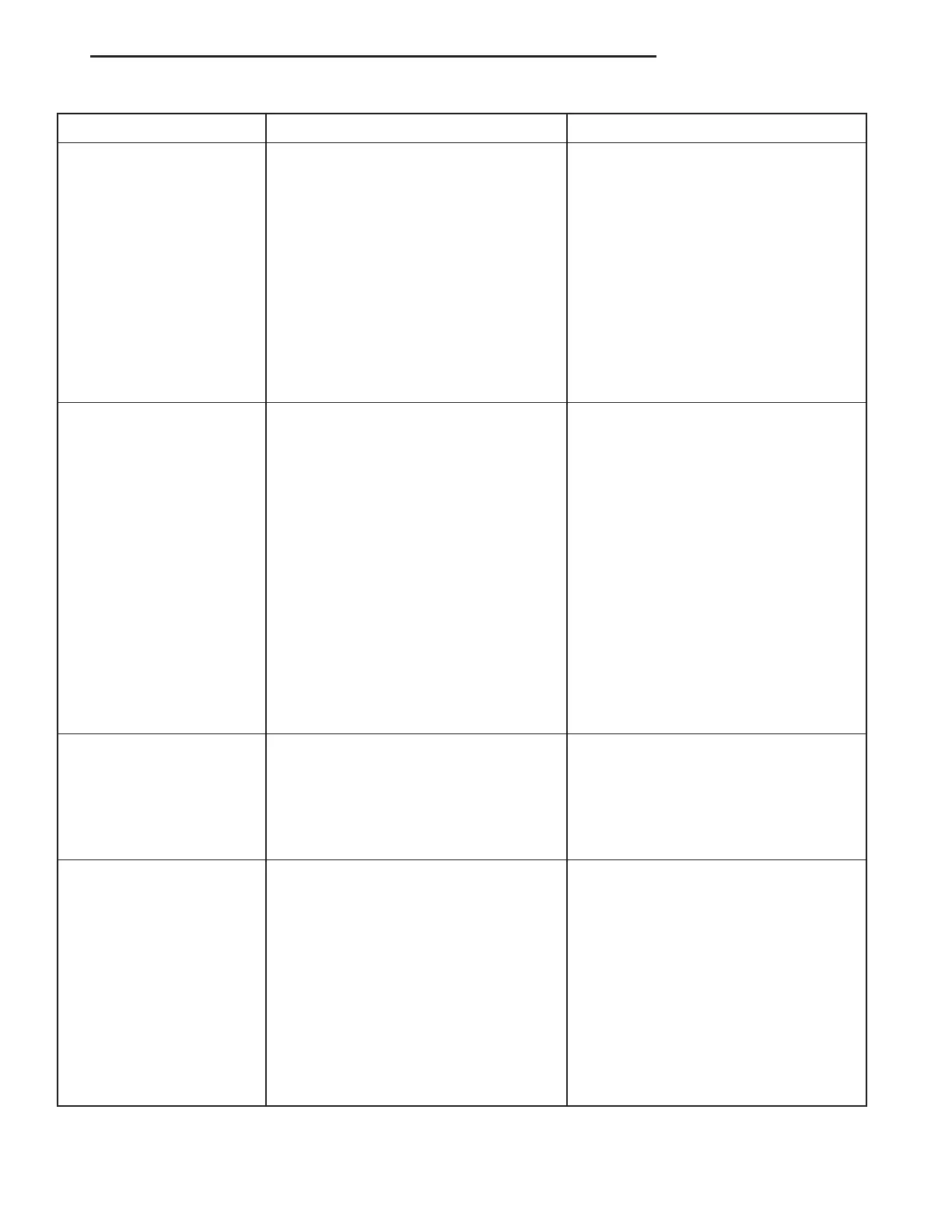

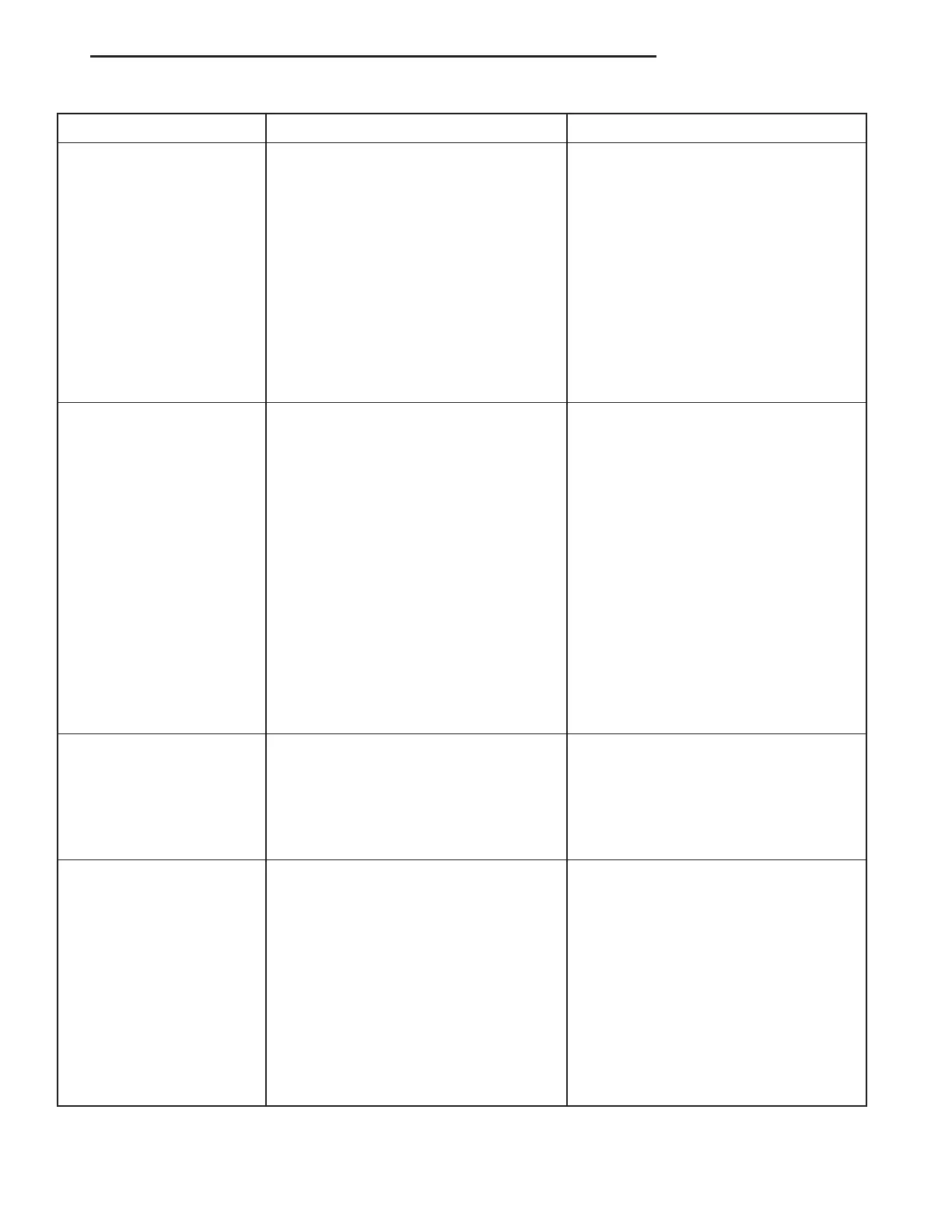

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct

clearance. Repair as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on

flanges.

6. Crankshaft journal out-of-round or

worn.

6. Replace crankshaft or grind journals.

7. Loose flywheel or torque converter. 7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main bearing

oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean, or

replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new tube

or clean, if necessary.

9. Oil pump cover warped or cracked. 9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated gaskets. 1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.

2. Tighten, repair or replace the part.

3. Misaligned or deteriorated cup or

threaded plug.

3. Replace as necessary.

OIL CONSUMPTION OR

SPARK PLUGS FOULED

1. PCV system malfunction. 1. Check system and repair as

necessary. Refer to EMISSION

CONTROL SYSTEMS.

2. Worn, scuffed or broken rings. 2. Hone cylinder bores. Install new rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check grooves. If

groove is not proper width, replace

piston.

5. Worn valve guide(s). 5. Ream guide(s) and replace valve(s)

with oversize valve(s) and seal(s).

6. Valve stem seal(s) worn or damaged. 6. Replace seal(s).

LH 3.2/3.5L ENGINE 9 - 85

DIAGNOSIS AND TESTING (Continued)

Loading...

Loading...