PISTON RING—FITTING

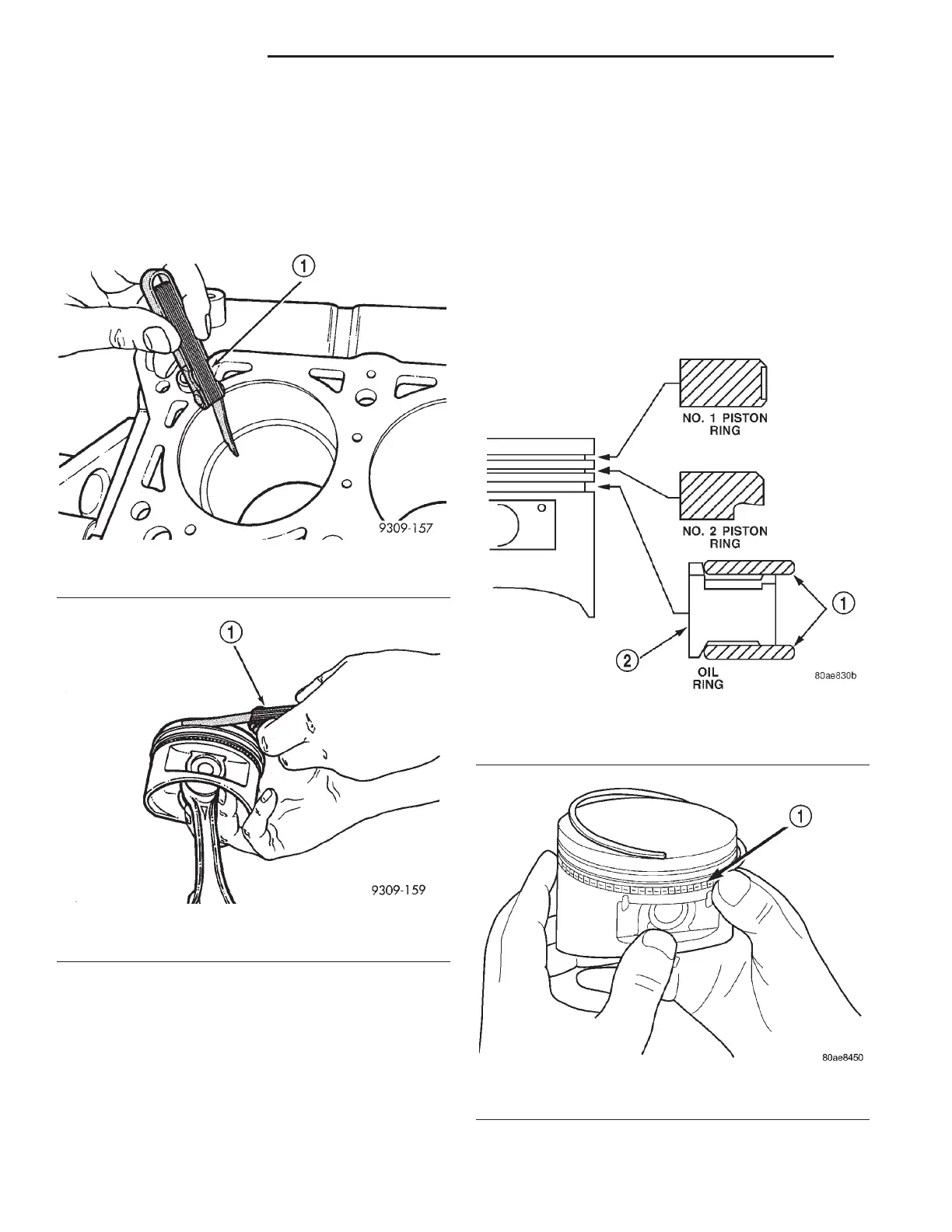

(1) Wipe cylinder bore clean. Insert ring and push

down with piston to ensure it is square in bore. The

ring gap measurement must be made with the ring

positioning at least 12 mm (0.50 inch.) from bottom

of cylinder bore. Check gap with feeler gauge (Fig.

22). Refer to Engine Specifications.

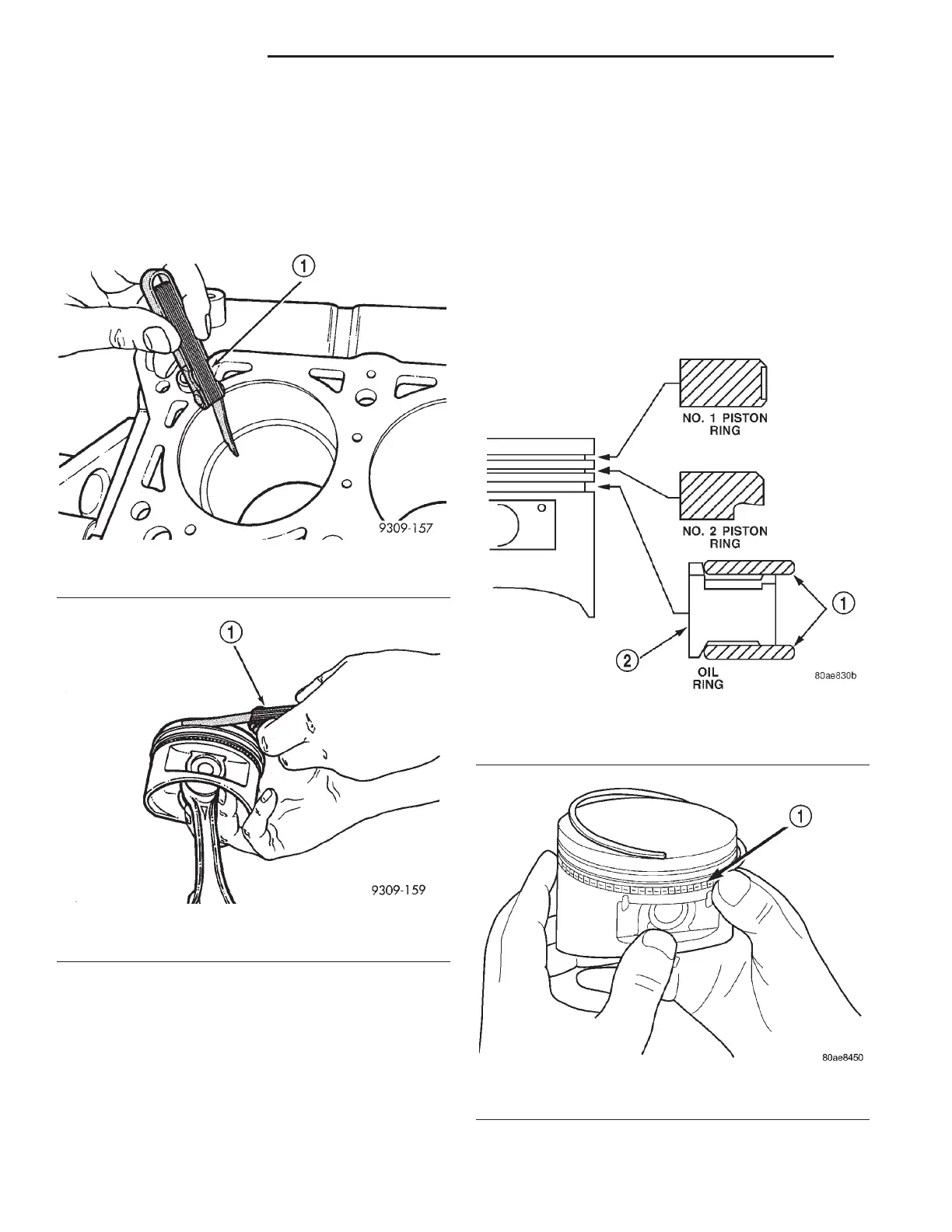

(2) Check piston ring to groove clearance: (Fig. 23).

Refer to Engine Specifications.

PISTON RINGS—INSTALLATION

(1) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Insure that the No. 2 ring is

installed with manufacturers I.D. mark (dot) facing

up, towards top of the piston (Fig. 24).

CAUTION: Install piston rings in the following

order:

(2) Oil ring expander.

(3) Upper oil ring side rail.

(4) Lower oil ring side rail.

(5) No. 2 Intermediate piston ring.

(6) No. 1 Upper piston ring.

(7) Install the side rail by placing one end between

the piston ring groove and the expander. Hold end

firmly and press down the portion to be installed

until side rail is in position. Do not use a piston

ring expander during this step (Fig. 25).

Fig. 22 Check Gap on Piston Rings

1 – FEELER GAUGE

Fig. 23 Measuring Piston Ring Side Clearance

1 – FEELER GAUGE

Fig. 24 Piston Ring—Installation

1 – SIDE RAIL

2 – SPACER EXPANDER

Fig. 25 Side Rail—Installation

1 – SIDE RAIL END

9 - 96 3.2/3.5L ENGINE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...