(8) Install upper side rail first and then the lower

side rail.

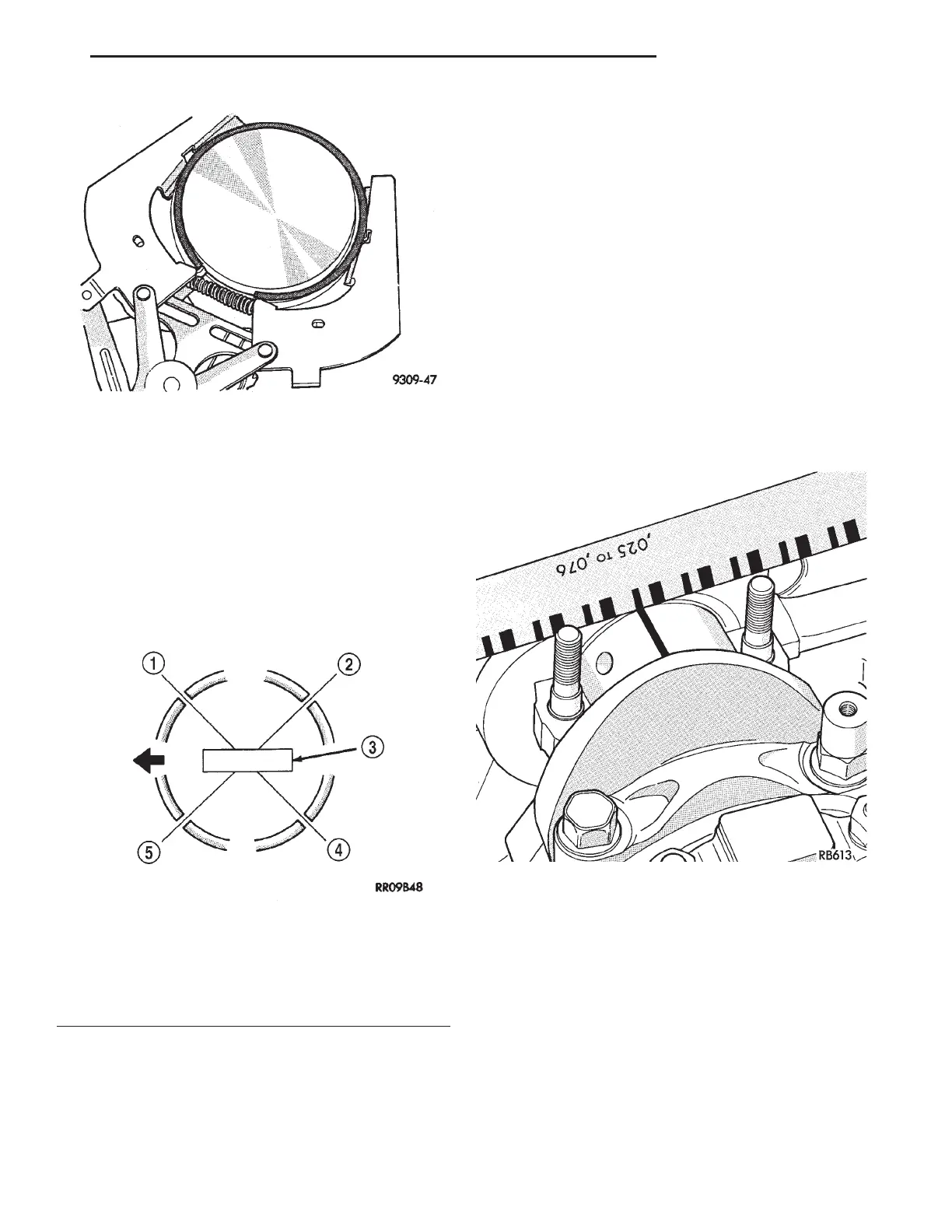

(9) Install No. 2 piston ring and then No. 1 piston

ring (Fig. 26).

(10) Position piston ring end gaps as shown in

(Fig. 27).

(11) Position oil ring expander gap at least 45°

from the side rail gaps but not on the piston pin cen-

ter or on the thrust direction. Staggering ring gap is

important for oil control.

CONNECTING ROD BEARING—INSTALLATION

Fit all rods on one bank until complete.

The bearing caps are not interchangeable and

should be marked at removal to insure correct

assembly.

The bearing shells must be installed with the

tangs inserted into the machined grooves in the rods

and caps. Install cap with the tangs on the same side

as the rod.

Limits of taper or out-of-round on any crankshaft

journals should be held to 0.015 mm (0.0006 in.).

Bearings are available in 0.025 mm (0.001 in.) and

0.254 mm (0.010 in.) undersize. Install the bear-

ings in pairs. Do not use a new bearing half

with an old bearing half. Do not file the rods or

bearing caps.

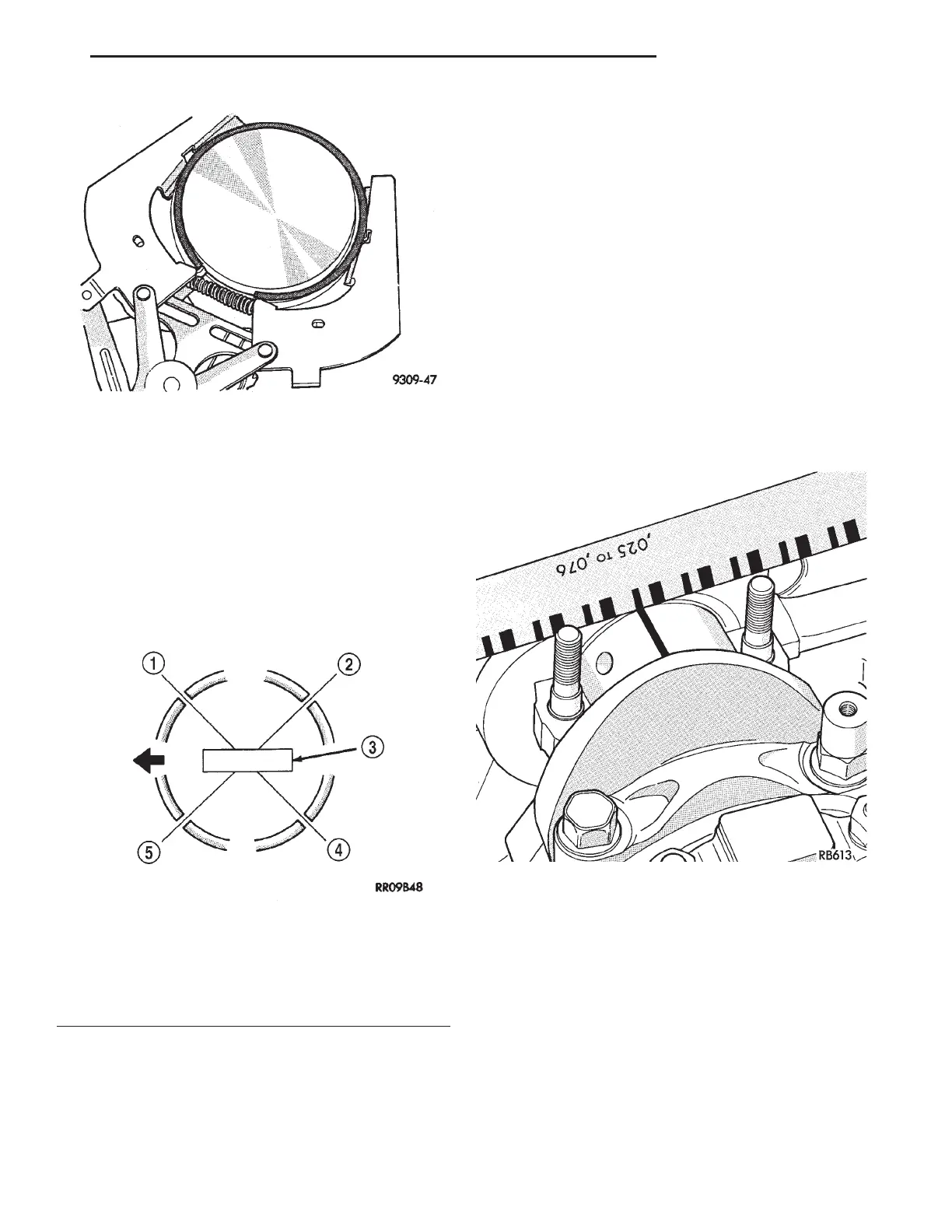

(1) Follow procedure specified in the Standard Ser-

vice Procedure Section for Measuring Main Bearing

Clearance and Connecting Rod Bearing Clearance

(Fig. 28). Refer to Engine Specifications.

NOTE: The rod bearing bolts should be examined

before reuse. If the threads are necked down the

bolts should be replaced (Fig. 29).

(2) Necking can be checked by holding a scale or

straight edge against the threads. If all the threads

do not contact the scale the bolt should be replaced.

(3) Before installing the nuts the threads should

be oiled with engine oil.

(4) Install nuts on each bolt finger tight then alter-

nately torque each nut to assemble the cap properly.

(5) Tighten the nuts to 54 N·m PLUS 1/4 turn (40

ft. lbs. PLUS 1/4 turn).

(6) Using a feeler gauge, check connecting rod side

clearance (Fig. 30). Refer to Engine Specifications.

Fig. 26 Upper and Intermediate Rings—Installation

Fig. 27 Piston Ring End Gap Position

1 – SIDE RAIL UPPER

2 – NO. 1 RING GAP

3 – PISTON PIN

4 – SIDE RAIL LOWER

5 – NO. 2 RING GAP AND SPACER EXPANDER GAP

Fig. 28 Checking Connecting Rod Bearing

Clearance—Typical

LH 3.2/3.5L ENGINE 9 - 97

SERVICE PROCEDURES (Continued)

Loading...

Loading...