CRANKSHAFT OIL SEAL—FRONT

REMOVAL

(1) Remove timing belt. Refer to procedure in this

section.

(2) Remove crankshaft sprocket using Special Tool

L-4407-A (Fig. 104).

(3) Tap the dowel pin out of the crankshaft (Fig.

105).

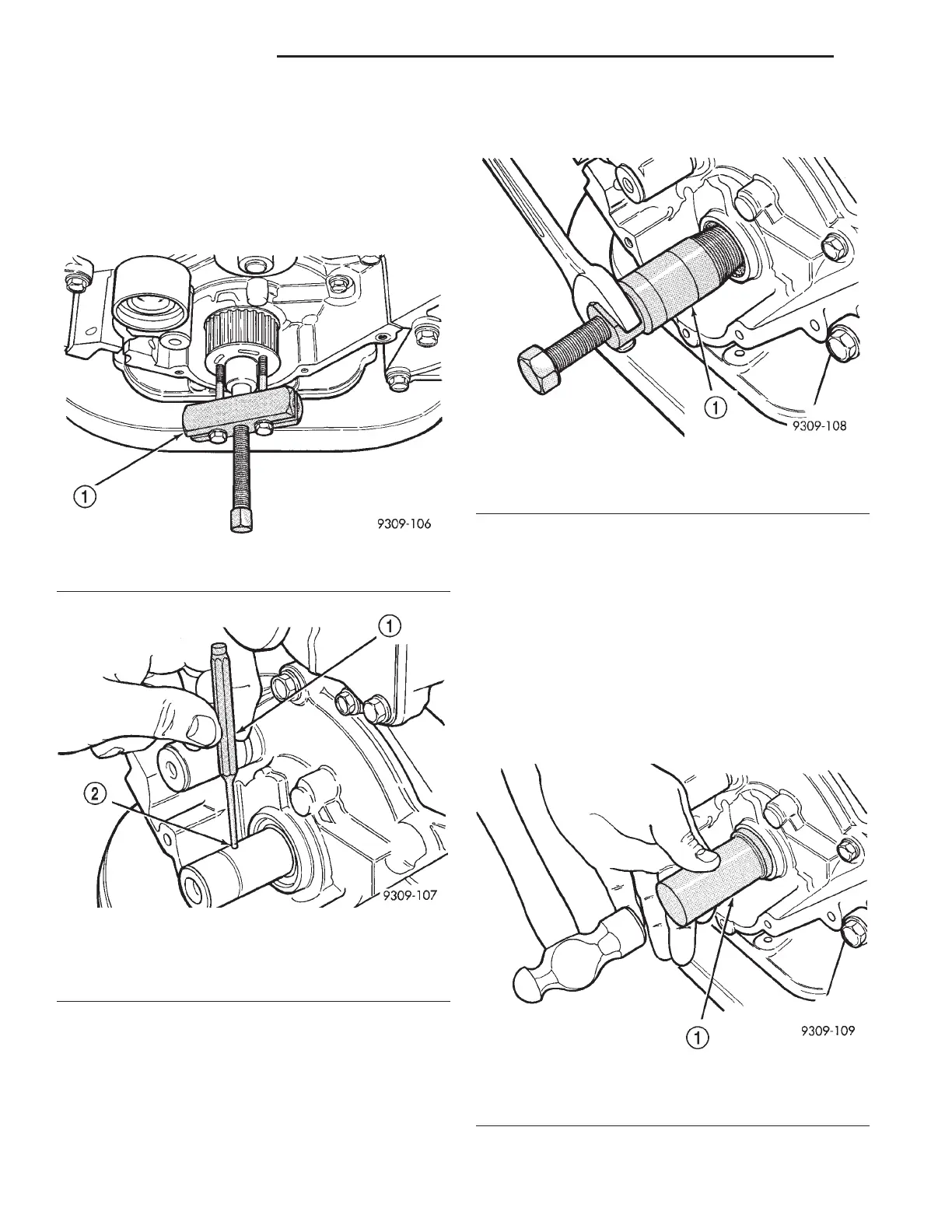

(4) Remove crankshaft seal using Special Tool

6341A (Fig. 106).

CAUTION: Do not nick shaft seal surface or seal

bore.

(5) Shaft seal lip surface must be free of varnish,

dirt or nicks. Polish with 400 grit paper if necessary.

INSTALLATION

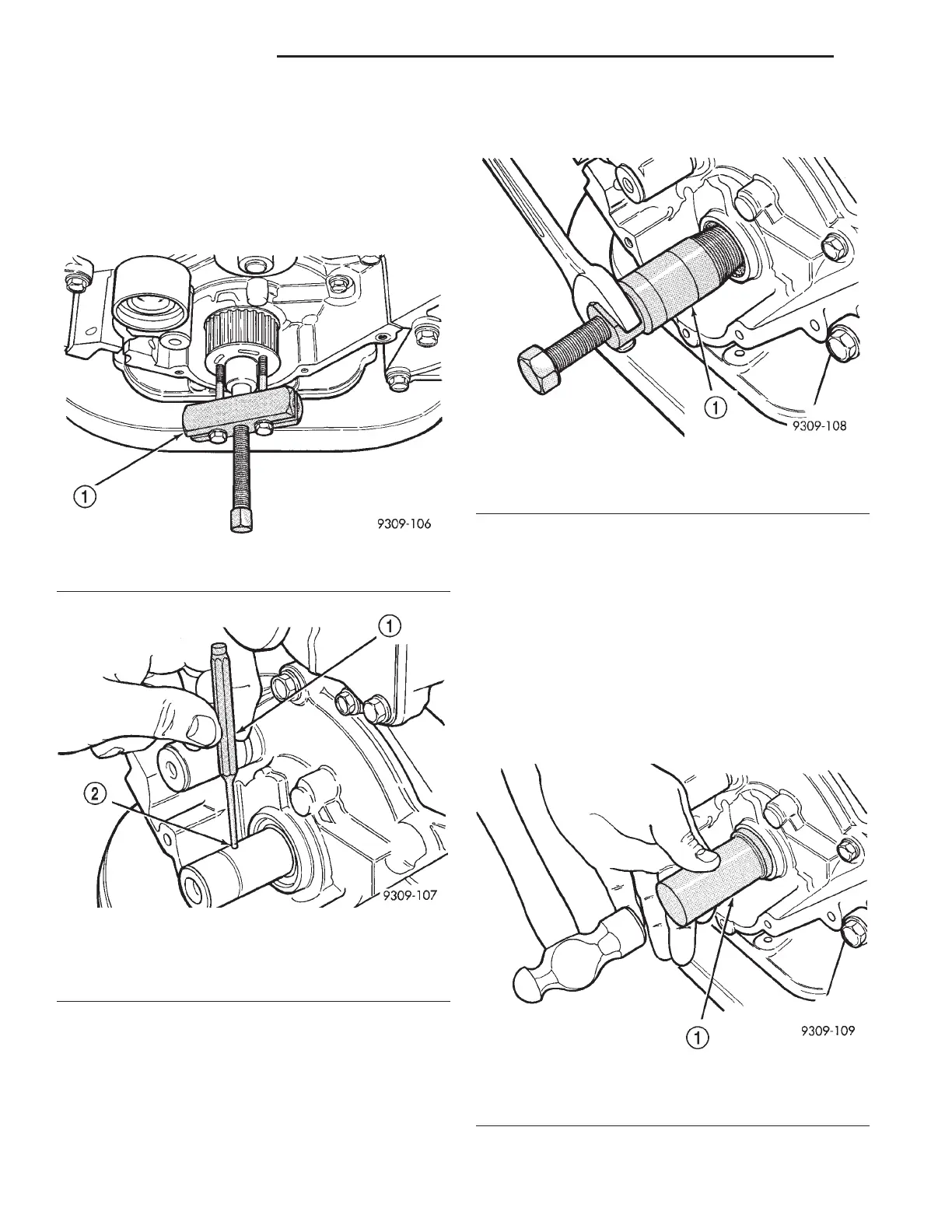

(1) Install crankshaft seal using Special Tool 6342

(Fig. 107).

(2) Install the dowel pin into the crankshaft to 1.2

mm (0.047 in.) protrusion (Fig. 105).

NOTE: To assure proper installation depth of crank-

shaft sprocket, Special Tool 6641 must be used.

(3) Install crankshaft sprocket using Special Tools

6641 and C-4685-C1 (Fig. 108).

(4) Install timing belt.

Fig. 104 Crankshaft Sprocket—Removal

1 – SPECIAL TOOL L-4407–A

Fig. 105 Crankshaft Sprocket Dowel Pin—Removal/

Installation

1 – PIN PUNCH

2 – DOWEL

Fig. 106 Crankshaft Oil Seal with Special Tool

6341A—Removal

1 – SPECIAL TOOL 6341A

Fig. 107 Crankshaft Oil Seal with Special Tool

6342—Installation

1 – SPECIAL TOOL 6342

9 - 128 3.2/3.5L ENGINE LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...