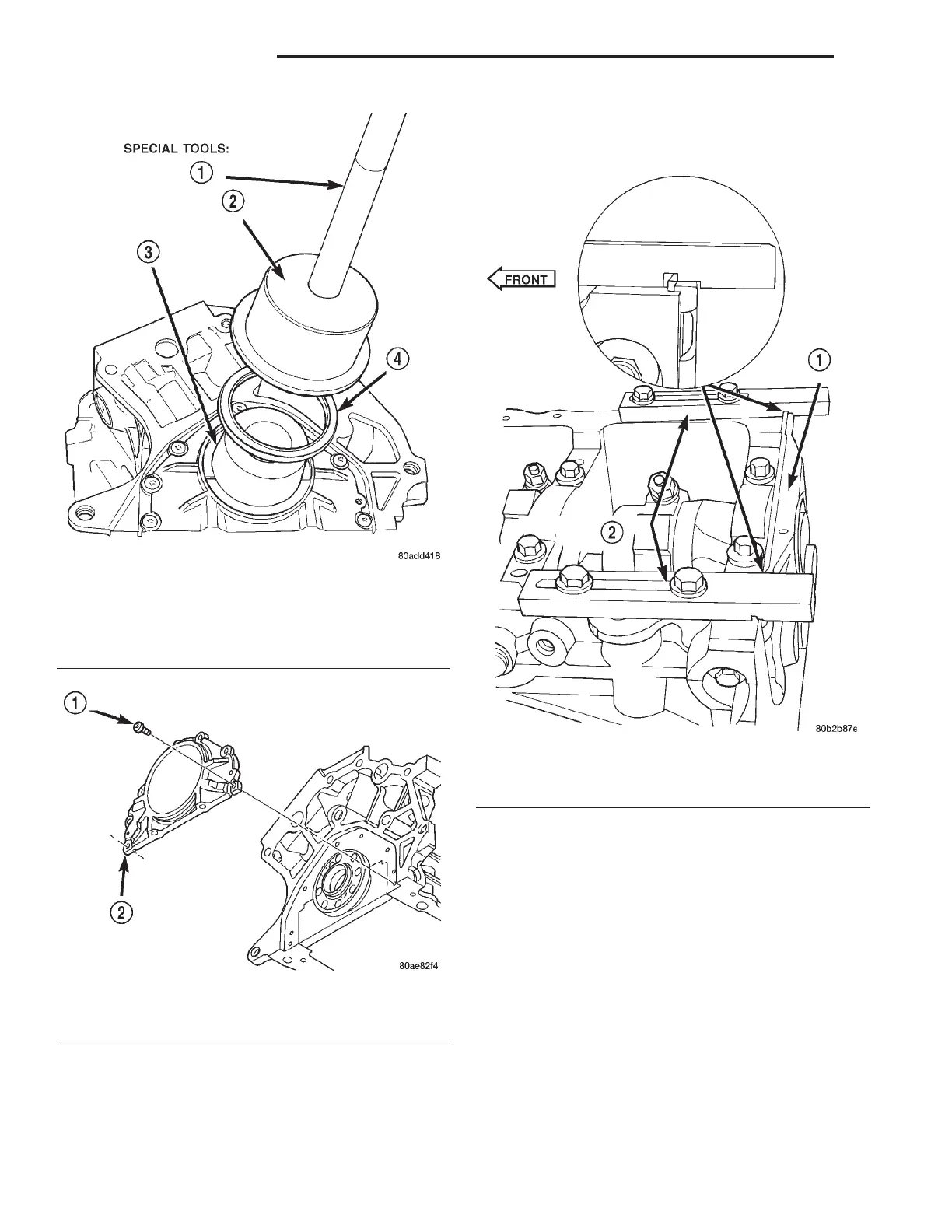

NOTE: Make sure the marking “3.2/3.5L” on Special

Tools 8225, is facing towards the cylinder block pan

rail surface (notch on tool is towards the seal

retainer).

(4) While applying firm pressure to the seal

retainer against Special Tools 8225 (Fig. 112), tighten

seal retainer screws to 12 N·m (105 in. lbs.).

(5) Install crankshaft rear oil seal and oil pan.

Refer to procedures in this section.

CRANKSHAFT MAIN BEARINGS

Bearing caps are not interchangeable and are

marked to insure correct assembly (Fig. 113). Upper

and lower bearing halves are NOT interchangeable.

CRANKSHAFT MAIN JOURNALS

The crankshaft journals should be checked for

excessive wear, taper and scoring. Limits of taper or

out-of-round on any crankshaft journals should be

held to 0.015 mm (0.0006 in.). Journal grinding

should not exceed 0.305 mm (0.012 inch.) under the

standard journal diameter. DO NOT grind thrust

faces of Number 2 main bearing. DO NOT nick crank

pin or bearing fillets. After grinding, remove rough

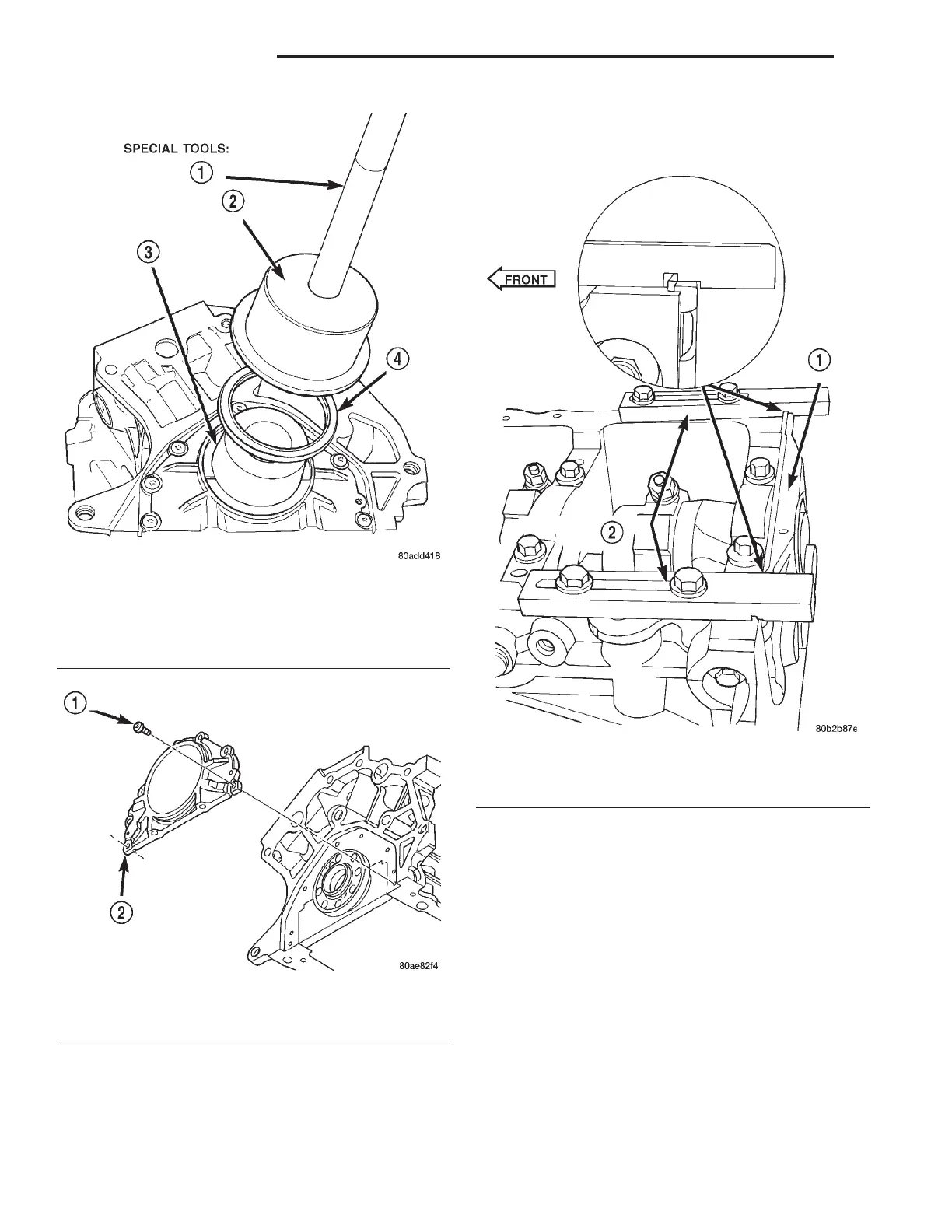

Fig. 110 Crankshaft Rear Seal—Installation

1 – C-4171 HANDLE

2 – 6926–2 INSTALLER

3 – 6926–1 GUIDE

4 – SEAL

Fig. 111 Oil Seal Retainer

1 – SCREWS (7)

2 – SEAL RETAINER

Fig. 112 Rear Crankshaft Seal Retainer Alignment

1 – SEAL RETAINER

2 – SPECIAL TOOLS 8225

9 - 130 3.2/3.5L ENGINE LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...