edges from crankshaft oil holes and clean out all pas-

sages.

CAUTION: With a forged steel crankshaft it is

important that the final paper or cloth polish after

any journal regrind be in the same direction as nor-

mal rotation in the engine.

The crankshaft thrust is controlled with thrust

washers located at the upper No. 2 main bearing

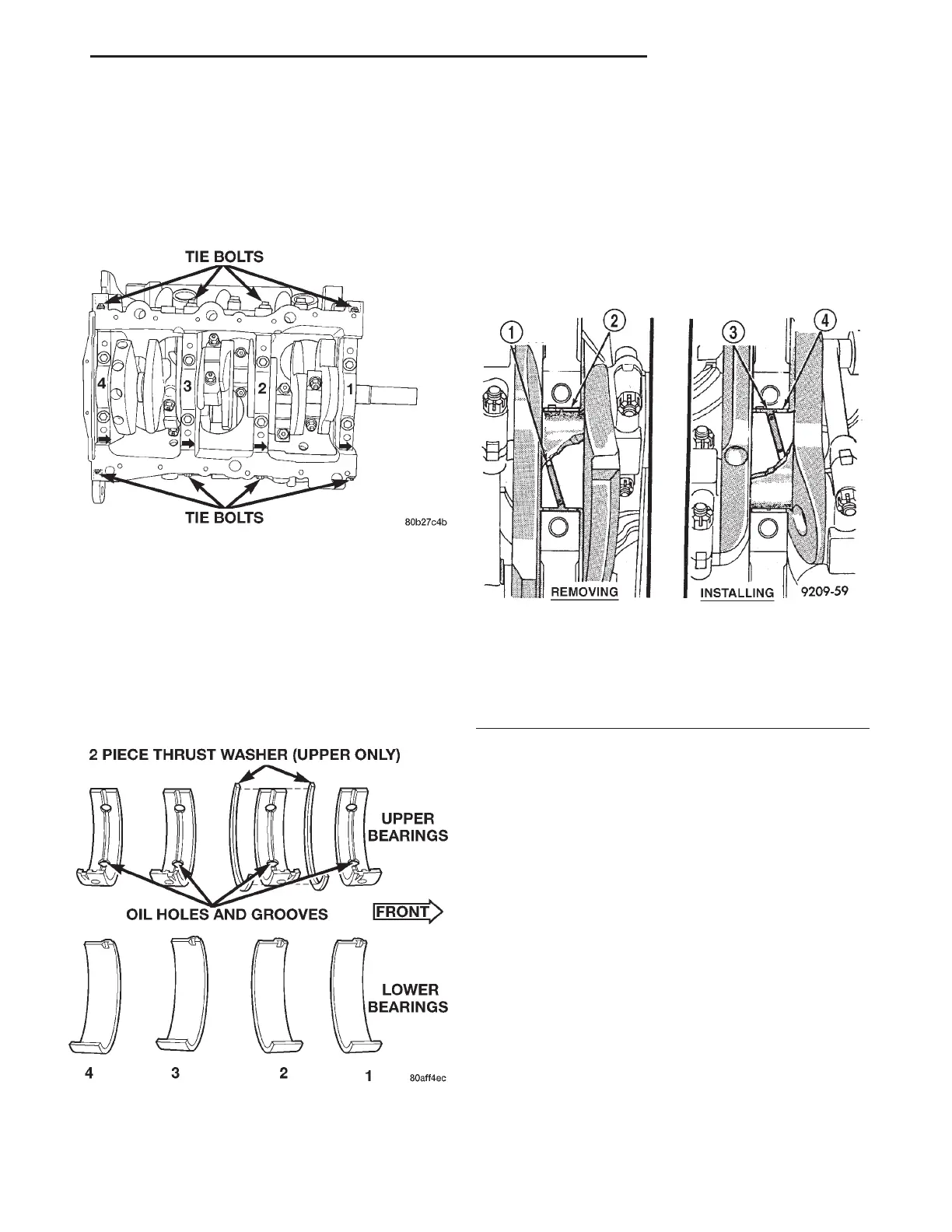

bulk head (Fig. 114). All bearing cap bolts removed

during service procedures are to be cleaned and oiled

before installation. Bearing shells are available in

standard and the following undersize: 0.025 mm

(0.001 in.) and 0.254 mm (0.010 in.). Never install an

undersize bearing that will reduce clearance below

specifications.

REMOVAL

(1) Remove oil pan, pick-up tube, and windage

tray. Refer to procedures in this section. Identify

bearing caps before removal.

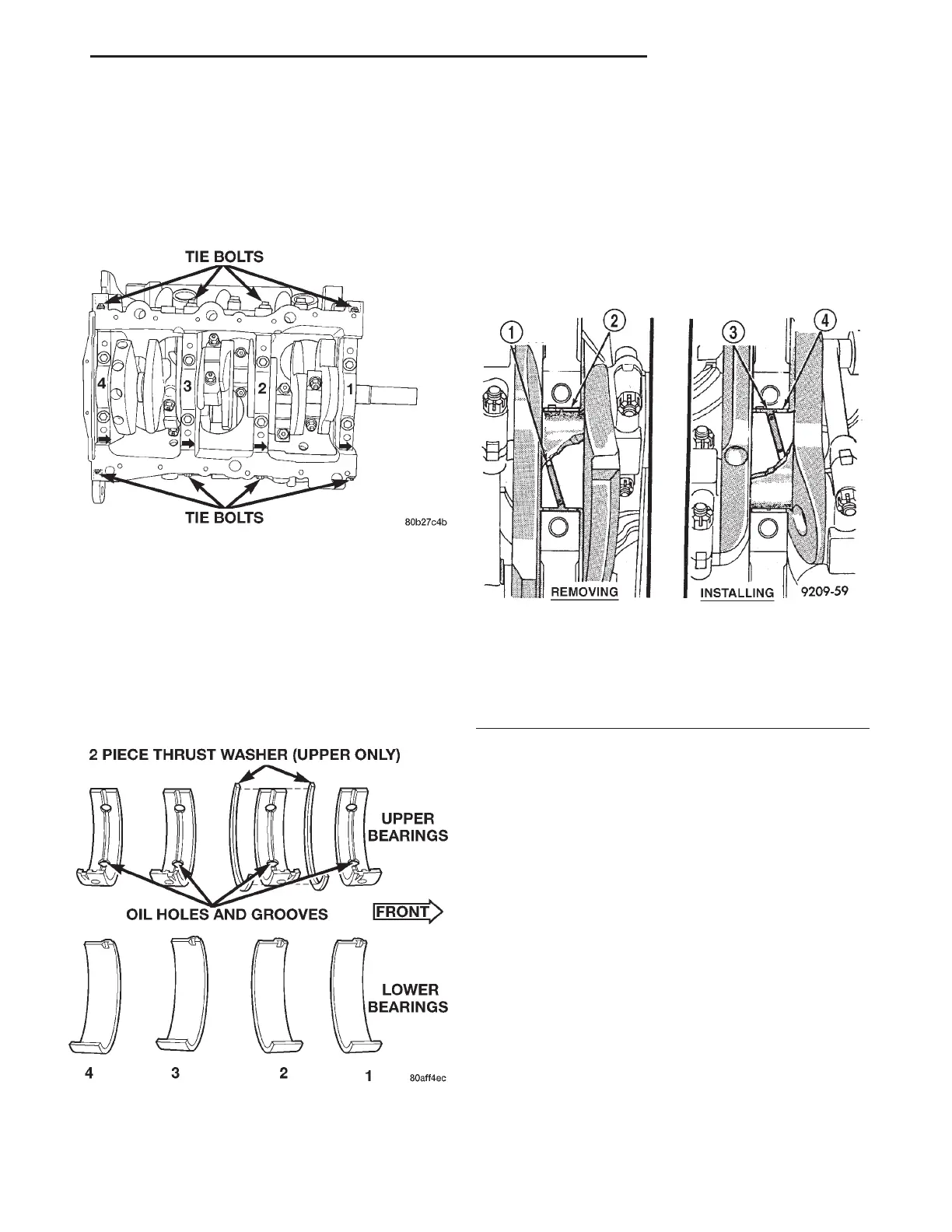

(2) Remove bearing caps one at a time. Remove

upper half of bearing by inserting Special Main Bear-

ing Tool C-3059 (Fig. 115) into the oil hole of crank-

shaft.

(3) Slowly rotate crankshaft clockwise, forcing out

upper half of bearing shell.

INSTALLATION

CAUTION: Main bearings are select fit. Refer to

Crankshaft Main Bearing Fitting in this section for

proper bearing selection.

NOTE: Only one main bearing should be selectively

fitted while all other main bearing caps are properly

tightened.

When installing a new upper bearing shell, slightly

chamfer the sharp edges from the plain side.

(1) Lubricate main bearing with clean engine oil.

(2) Start bearing in place, and insert Main Bearing

Tool C-3059 into oil hole of crankshaft (Fig. 115).

(3) Slowly rotate crankshaft counterclockwise slid-

ing the bearing into position. Remove Special Main

Bearing Tool C-3059.

NOTE: Lubricate main bearing cap bolts with

engine oil before installation.

Fig. 113 Main Bearing Cap Identification

Fig. 114 Main Bearing Identification

Fig. 115 Removing and Installing Upper Main

Bearing With Special Tool C- 3059

1 – SPECIAL TOOL C-3059

2 – BEARING

3 – SPECIAL TOOL C-3059

4 – BEARING

LH 3.2/3.5L ENGINE 9 - 131

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...