(4) Lubricate and install lower bearing half and

main cap Tighten bolts finger tight.

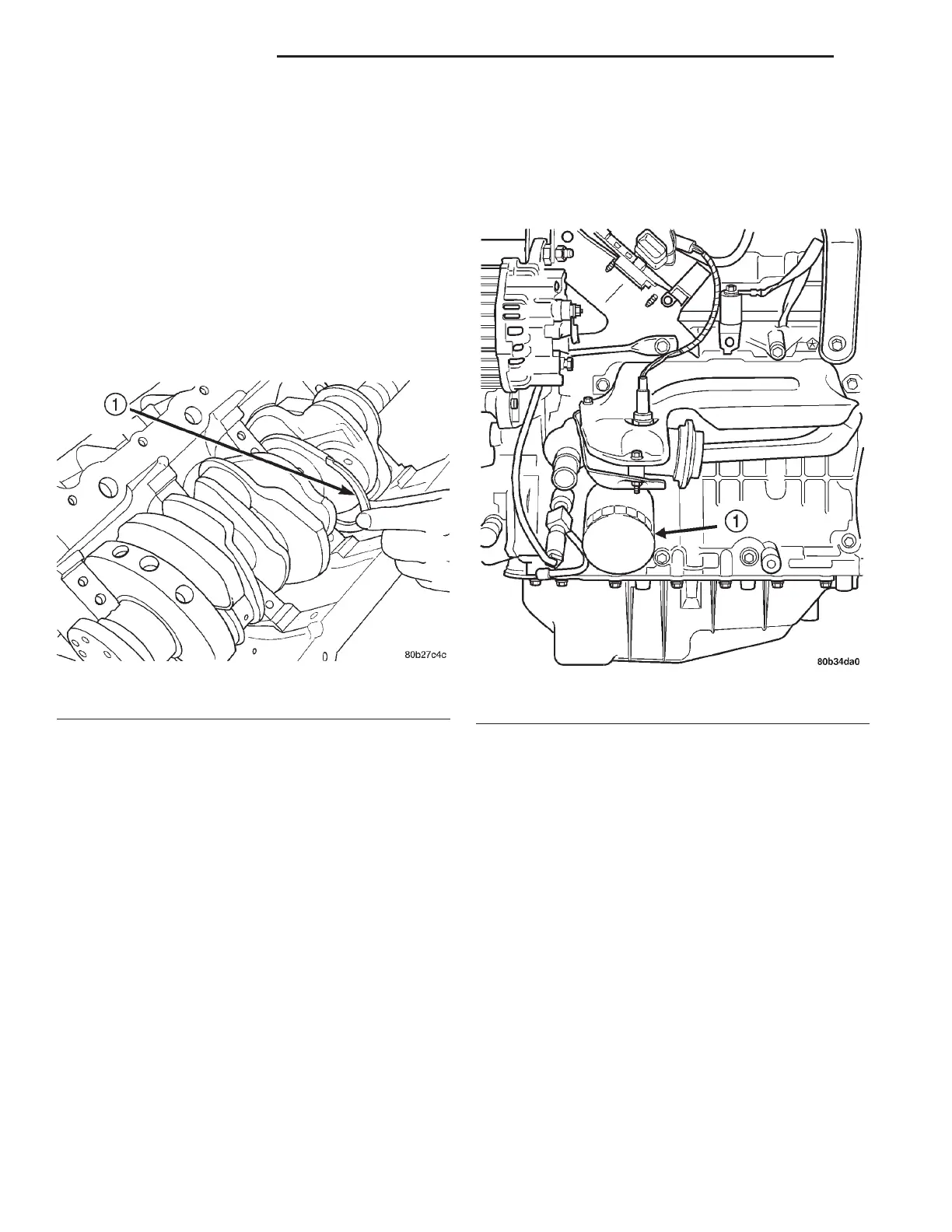

(5) For installing thrust washers at the No. 2 main

bearing location, use the following procedure:

(a) Move crankshaft forward to limit of travel.

Lubricate and install the front thrust washer by

rolling the washer onto the machined shelf

between the No. 2 upper main bulk head and

crankshaft thrust surface (Fig. 116).

(b) Move crankshaft rearward to limit of travel.

Lubricate and install the rear thrust washer by

rolling the washer onto the machined shelf

between the No. 2 upper main bulk head and

crankshaft thrust surface.

The main bearing cap bolts must be tightened in

the proper sequence. First the inner main cap bolts,

secondly the windage tray bolts, lastly the main cap

tie (horizontal) bolts.

(6) Install each main bearing cap and tighten

inner bolts finger tight.

(7) Tighten inner main bearing cap bolts to 20 N·m

+ 1/4 turn (15 ft. lbs. + 1/4 turn).

(8) Measure crankshaft end play. Refer to Service

Procedures in this section.

(9) Install windage tray. Lubricate bolts with

engine oil and tighten to 27 N·m + 1/4 turn (20 ft.

lbs. + 1/4 turn).

(10) Install the main cap tie (horizontal) bolts and

tighten to 28 N·m (250 in. lbs.).

(11) Install oil pump pick-up tube and oil pan.

(12) Fill engine crankcase with proper oil to cor-

rect level.

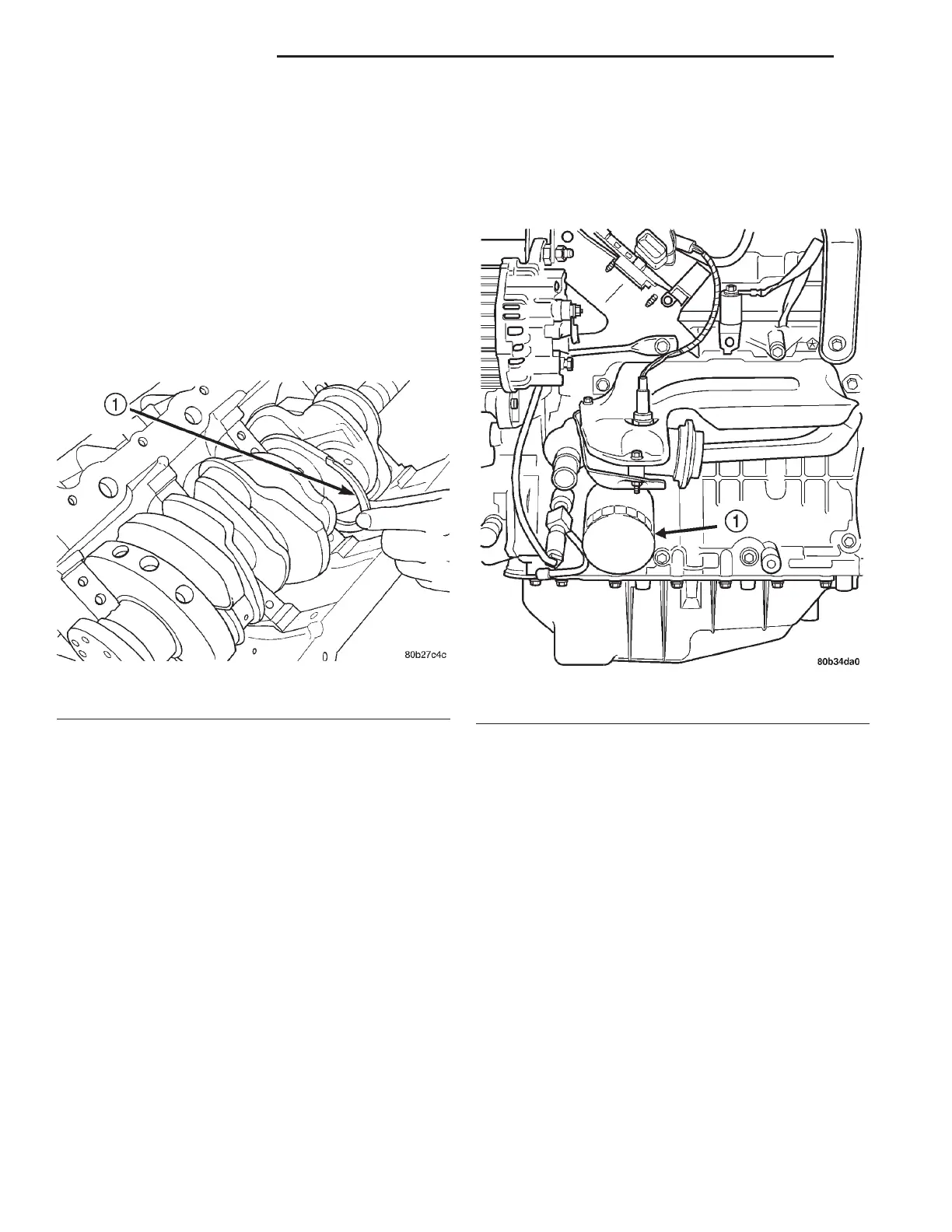

OIL FILTER

NOTE: When servicing the oil filter, avoid deform-

ing the filter can. Install the remove/install tool band

strap against the base lock seam. The lock seam

joining the can to the base is reinforced by the

base plate.

(1) Using a suitable oil filter wrench, unscrew fil-

ter from base and discard (Fig. 117).

(2) Wipe base clean, then inspect gasket contact

surface.

(3) Lubricate gasket of new filter with clean

engine oil.

(4) Install and tighten filter to 20 N·m (15 ft. lbs.)

of torque after gasket contacts base. Use filter

wrench if necessary.

(5) Start engine and check for leaks.

OIL PUMP

REMOVAL

It is necessary to remove the oil pan, oil pickup

and oil pump body to service the oil pump rotors. The

oil pump pressure relief valve can be serviced by

removing the oil pan.

(1) Drain cooling system and remove fan module.

Refer to COOLING SYSTEM for procedures.

(2) Remove the accessory drive belts. Refer to

COOLING SYSTEM for procedure.

(3) Remove the crankshaft damper and timing belt

covers. Refer to procedures in this section.

Fig. 116 Thrust Washer Installation

1 – FRONT THRUST WASHER

Fig. 117 Oil Filter

1 – OIL FILTER

9 - 132 3.2/3.5L ENGINE LH

REMOVAL AND INSTALLATION (Continued)

Loading...

Loading...