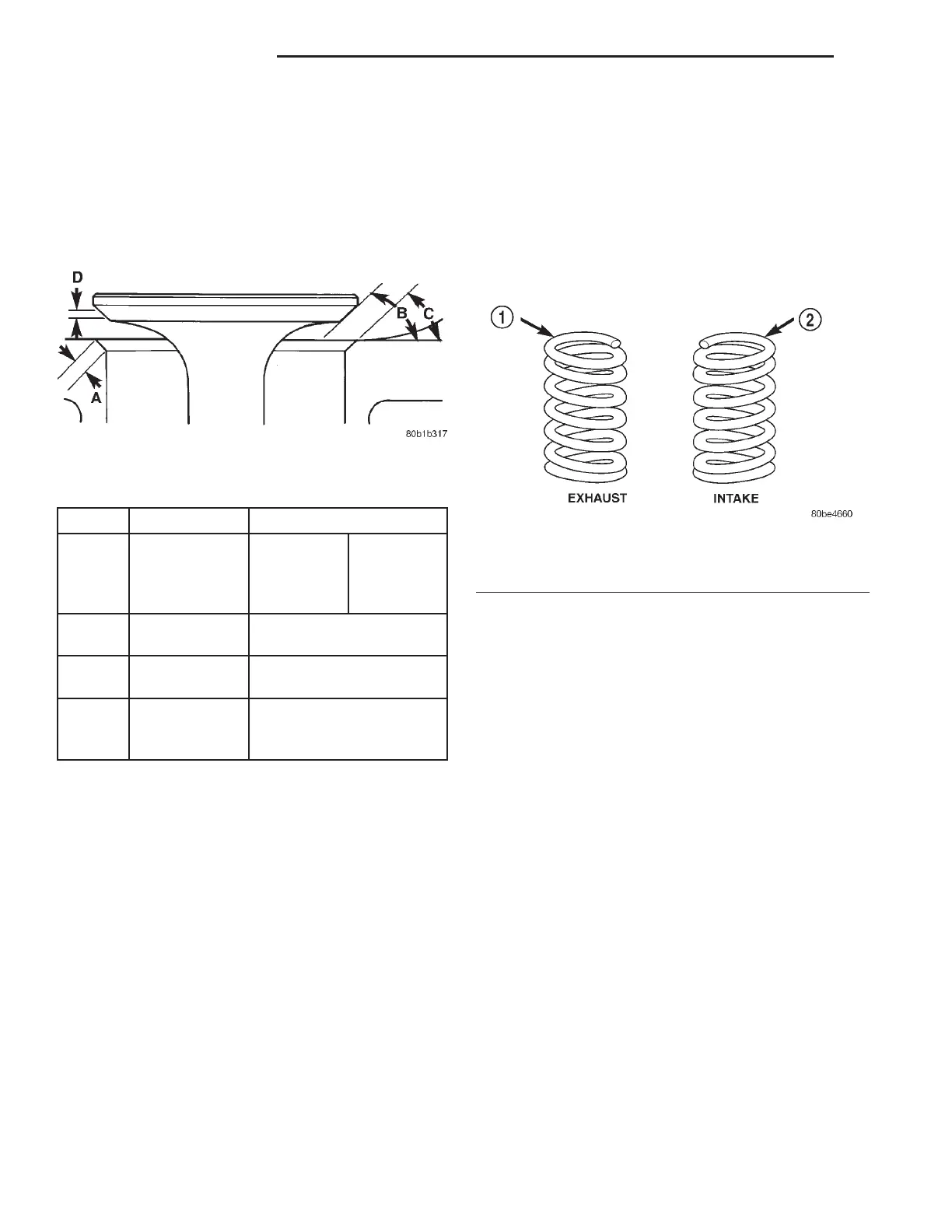

VALVE SEATS

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.

(2) Measure the concentricity of valve seat using

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch.) total indicator reading.

(3) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seat LIGHTLY with Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of valve face, then lower valve seat

with a 15 degree stone. If the blue is transferred to

the bottom edge of valve face, then raise valve seat

with a 65 degree stone.

NOTE: Valve seats which are worn or burned can

be reworked, provided that correct angle and seat

width are maintained. Otherwise cylinder head must

be replaced.

(4) When seat is properly positioned the width of

the intake seats should be 0.75 to 1.25 mm (0.0296 to

0.0493 in.) and exhaust seats should be 1.25 to 1.75

mm (0.049 to 0.069 in.) (Fig. 36).

(5) Check the valve spring installed height after

refacing the valve and seat (Fig. 38).

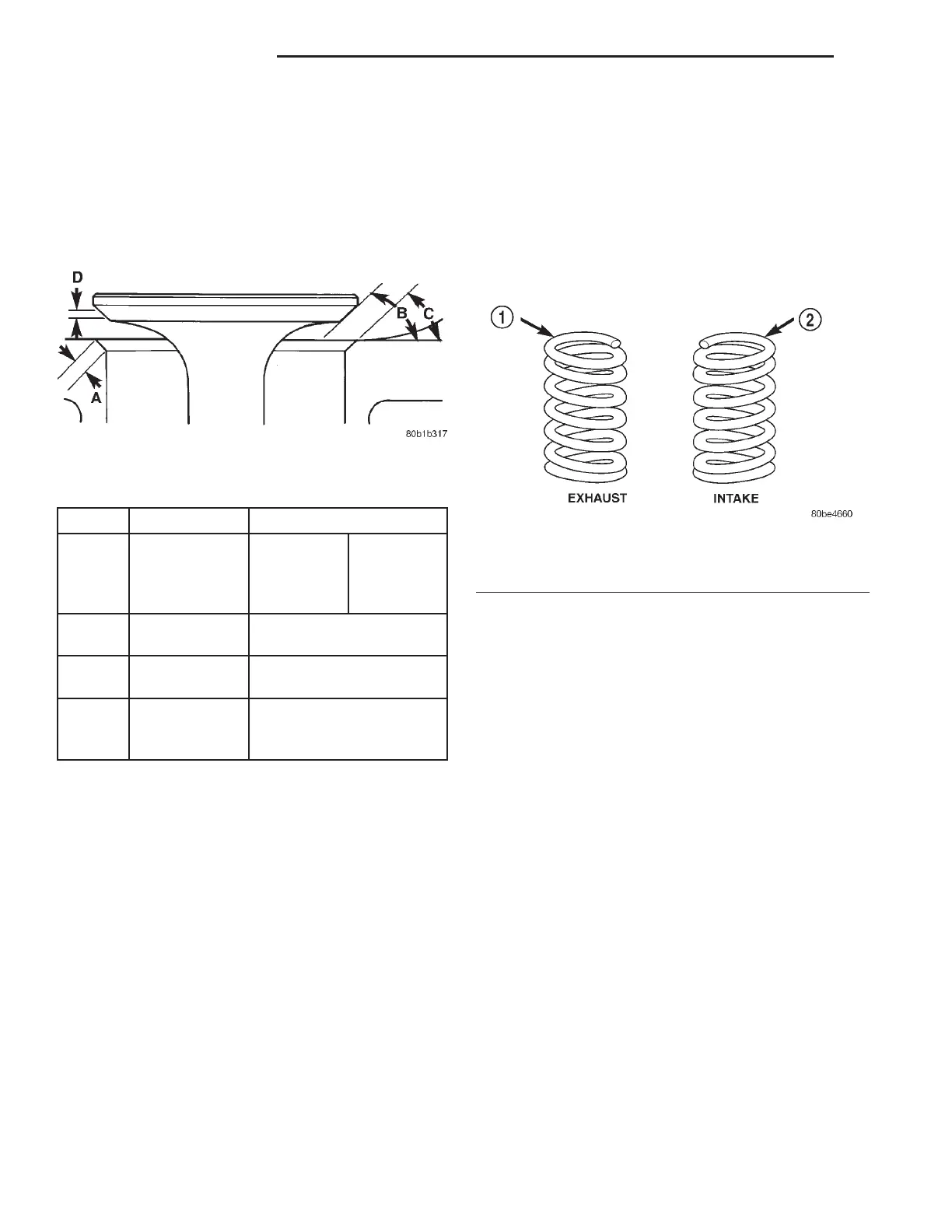

VALVE SPRING IDENTIFICATION

The valve springs are of two different lengths and

are wound in different directions. The valve springs

are color coded, intake spring is right hand coil direc-

tion with orange dye on the top coils and the exhaust

spring is left hand coil direction with a yellow dye on

the top coils (Fig. 37).

VALVE INSTALLATION

(1) Coat valve stems with clean engine oil and

insert them in cylinder head.

(2) If valves or seats have been reground, check

valve tip height (A) (Fig. 38). If valve tip height is

greater than 43.65 mm (1.7185 in.) intake or 45.98

mm (1.8102 in.) exhaust, grind valve tip until within

specifications. Make sure measurement is taken from

cylinder head surface to the top of valve stem.

(3) Install valve seal/spring seat assembly over

valve guides on all valve stems (Fig. 39). Ensure that

the garter spring is intact around the top of the rub-

ber seal. Place valve springs (color-coded end facing

up) and valve retainers into position.

(4) Compress valve springs with a valve spring

compressor, install locks and release tool. If valves

and/or seats are reground, measure the

installed height of springs (B) (Fig. 38), make

sure measurements are taken from top of

spring seat to the bottom surface of spring

retainer. If height is greater than 38.75 mm (1.5256

in.), install a 0.762 mm (0.030 in.) spacer in head

counterbore under the valve spring seat to bring

spring height back within specification.

Fig. 36 Valve Seats

ITEM DESCRIPTION SPECIFICATION

A Seat Width Intake:

0.75 – 1.25

mm (0.030

– 0.049 in.)

Exhaust:

1.25 – 1.75

mm (0.049

– 0.069 in.)

B Face Angle Intake & Exhaust: 44.5 –

45°

C Seat Angle Intake & Exhaust: 45 –

45.5°

D Seat Contact

Area

Valve to seat contact

must be at center of valve

face.

Fig. 37 Valve Spring Identification

1 – YELLOW DYE

2 – ORANGE DYE

9 - 100 3.2/3.5L ENGINE LH

SERVICE PROCEDURES (Continued)

Loading...

Loading...