electronics system to send information to the 6 printheads though each of the interconnects, and it receives

information from the sensors. Some parts aid the ink to arrive at the printheads. It also holds in position the

cutter, used to cut some types of substrate.

Carriage components

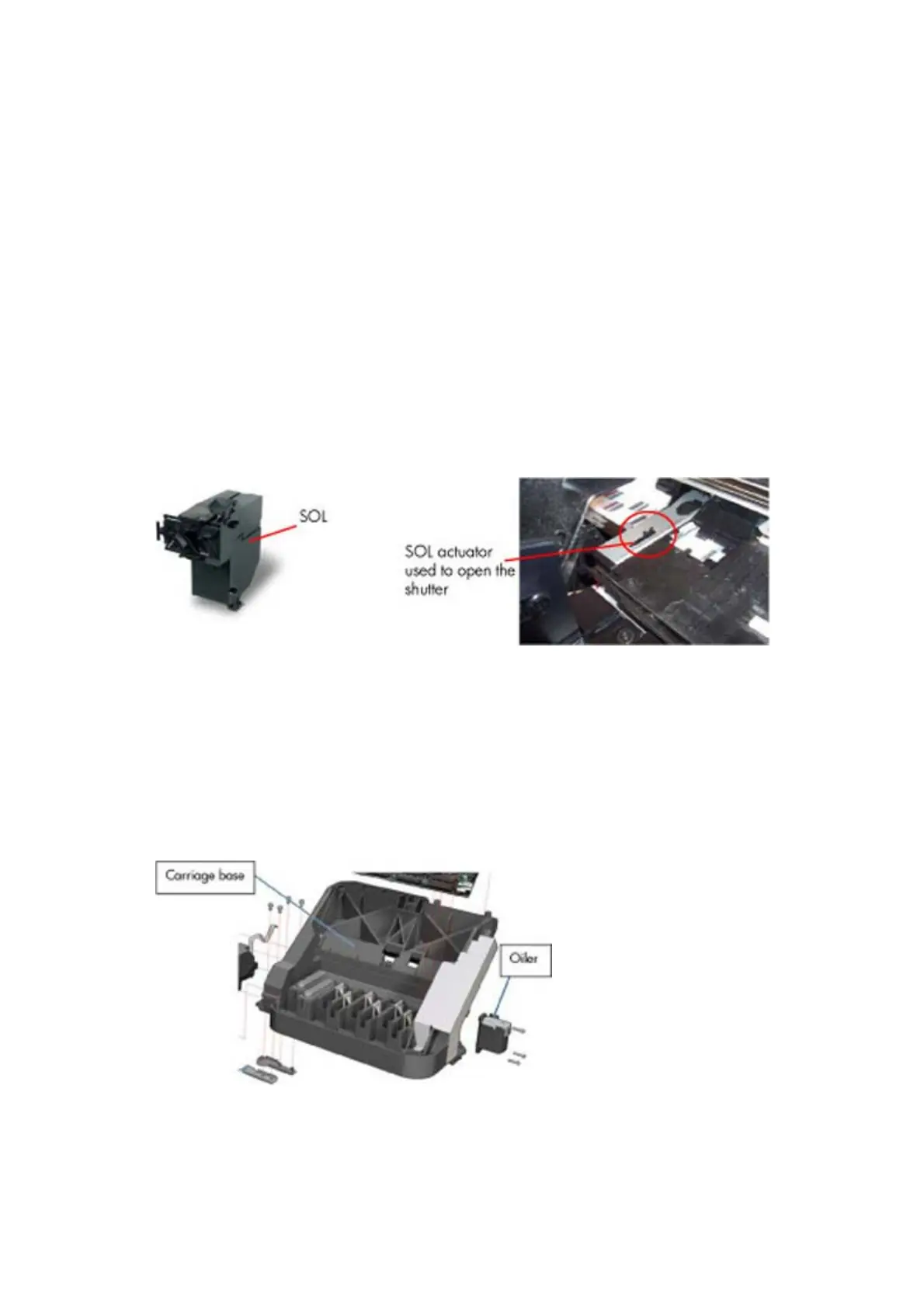

SOL Spectrophotometer (360 only)

SOL is a color sensor and it is placed in the left side of the carriage, covered by a metal sheet that protects it

from the heater’s high temperatures. The main function of SOL is to measure color samples that have been

printed on the loaded substrate and are placed on the print platen zone.

Before taking any color measurement, SOL must be initialized. The SOL initialization process lasts for about

7min. This process consists on 3 steps: sensor switch on, sensor warm up, and sensor calibration. When the

initialization has been completed, the shutter is opened automatically and the carriage is moved along the

scan axis to place SOL on top of each sample to take a color measurement. After the measurements, the

shutter is closed again and the sensor is switched off.

SOL is used to make the linearization from the RIP.

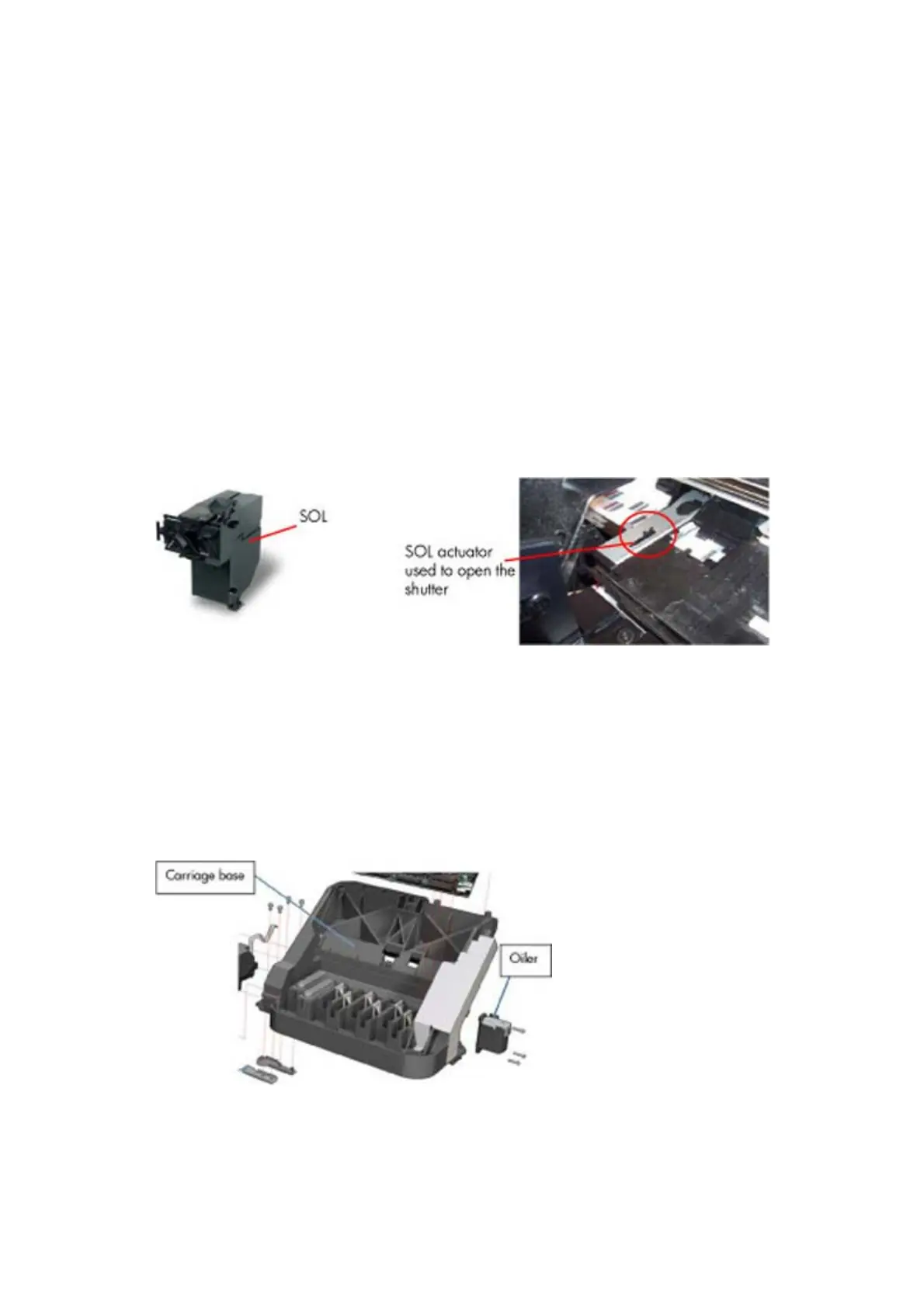

Carriage base

The main function of this plastic part is to located the printheads. Its position is enforced by the two rods and

the belt. It serves as a base where other parts are attached and it has some features to located other

components (capping station and all the next parts).

Oiler

The Oiler is a small system at the right-hand side of the carriage base that provides continuous lubrication to

the Slider Rod.

Latch assembly

This assembly holds down the printheads and helps to ensure that they do not move during operation. Once

the handle is opened it can rotate to allow the user to remove the printheads. It has some features (holes) to

ENWW Scan axis and carriage 33

Loading...

Loading...