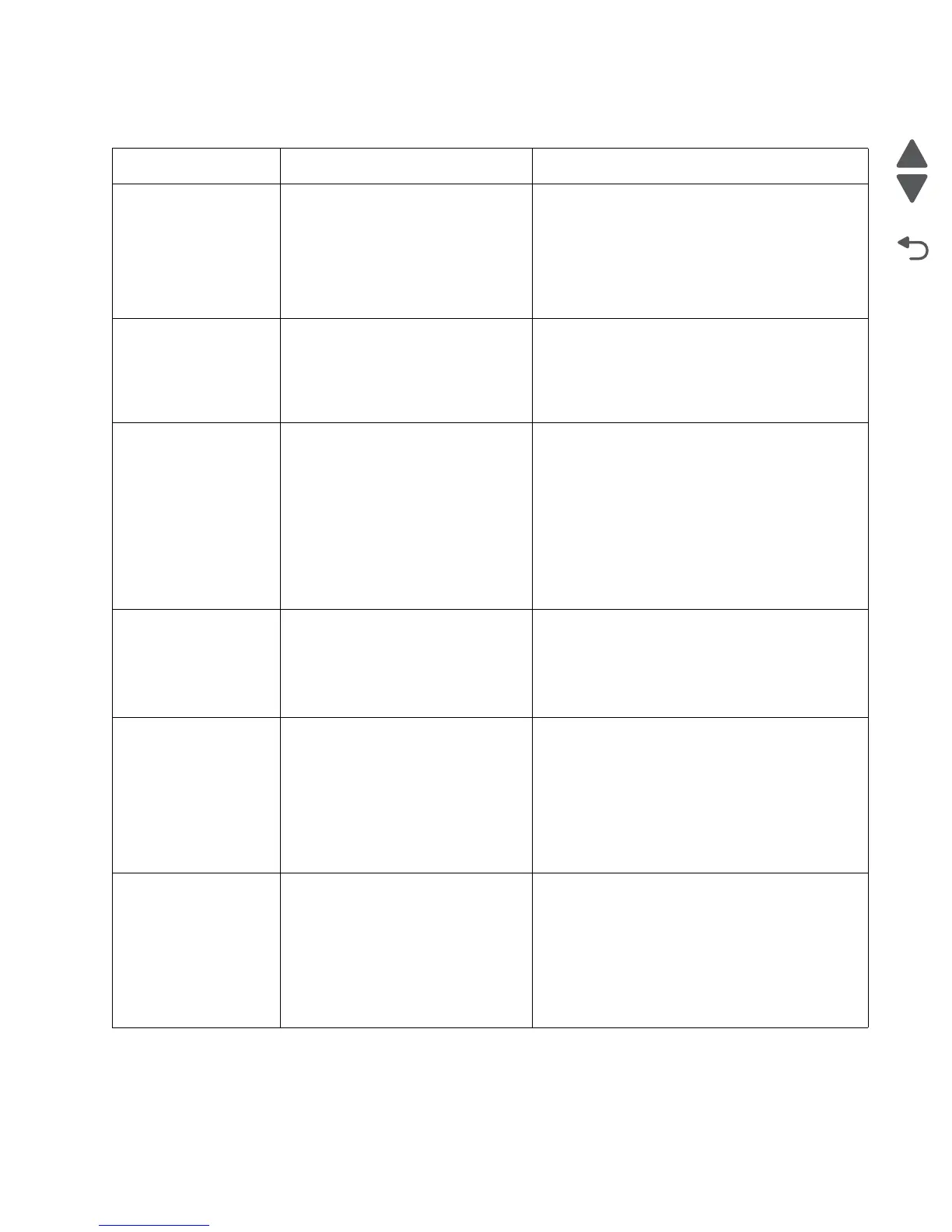

Diagnostic information 2-15

5062

Additional checks—24x paper jam

Error code Description Action

241.01 S1 sensor is made when printer

powers up or covers are closed.

Possible causes:

• Paper jam leaving page over

sensor

• Defective S1 sensor

• Faulty system card

1. Clear away anything in the paper path that might

cause the paper to jam.

2. If clearing a paper jam does not fix the problem,

go to “Input, S1, narrow media, and near

narrow media sensor service check” on

page 2-153.

241.02 Paper hit S1 sensor too soon.

Possible causes:

• Damaged S1 sensor flag or S1

sensor

• Loose input sensor

1. Clear away anything in the paper path that might

cause the paper to jam.

2. The input sensor may not be functioning

properly. Go to “241.02—Paper Jam error

service check” on page 2-108.

241.03 While feeding from tray 2, the paper

never reaches the next sensor.

Possible causes:

• Obstruction on the paper path

• Damaged media leading edge

• Incorrect paper loading

• Incorrect paper guide setting

• Jam clearance cover partially

open

• Drive assembly failure

1. Remove anything in the paper path.

2. Flex the media, and stack it flat in the tray.

3. Check if the jam clearance cover can close

properly.

4. If problem persists, go to “241.03, 242.03,

243.03, 244.03, 242.05, 243.05, 244.05,

245.05—Paper jam (550-sheet/2000-sheet

input option) service check” on page 2-110.

241.04 S1sensor flag broke early.

Possible cause:

• Incorrect paper settings

• Defective S1 sensor

• Faulty system board

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Go to “Input, S1, narrow media, and near

narrow media sensor service check” on

page 2-153.

241.05,

241.07

While feeding from tray 1, the S1 input

sensor is never made.

Possible causes:

• Incorrect paper loading

• Incorrect paper guide setting

• Pick rolls (tires) failure

• Paper pick mechanism failure

• System board failure

1. Remove all media present in the paper path.

2. Flex the media, and stack it flat in the tray or

multipurpose feeder.

3. Properly set paper guides in the paper tray.

4. Check the pick rolls (tires) and replace if worn.

5. If the problem persists, go to “Input, S1, narrow

media, and near narrow media sensor

service check” on page 2-153.

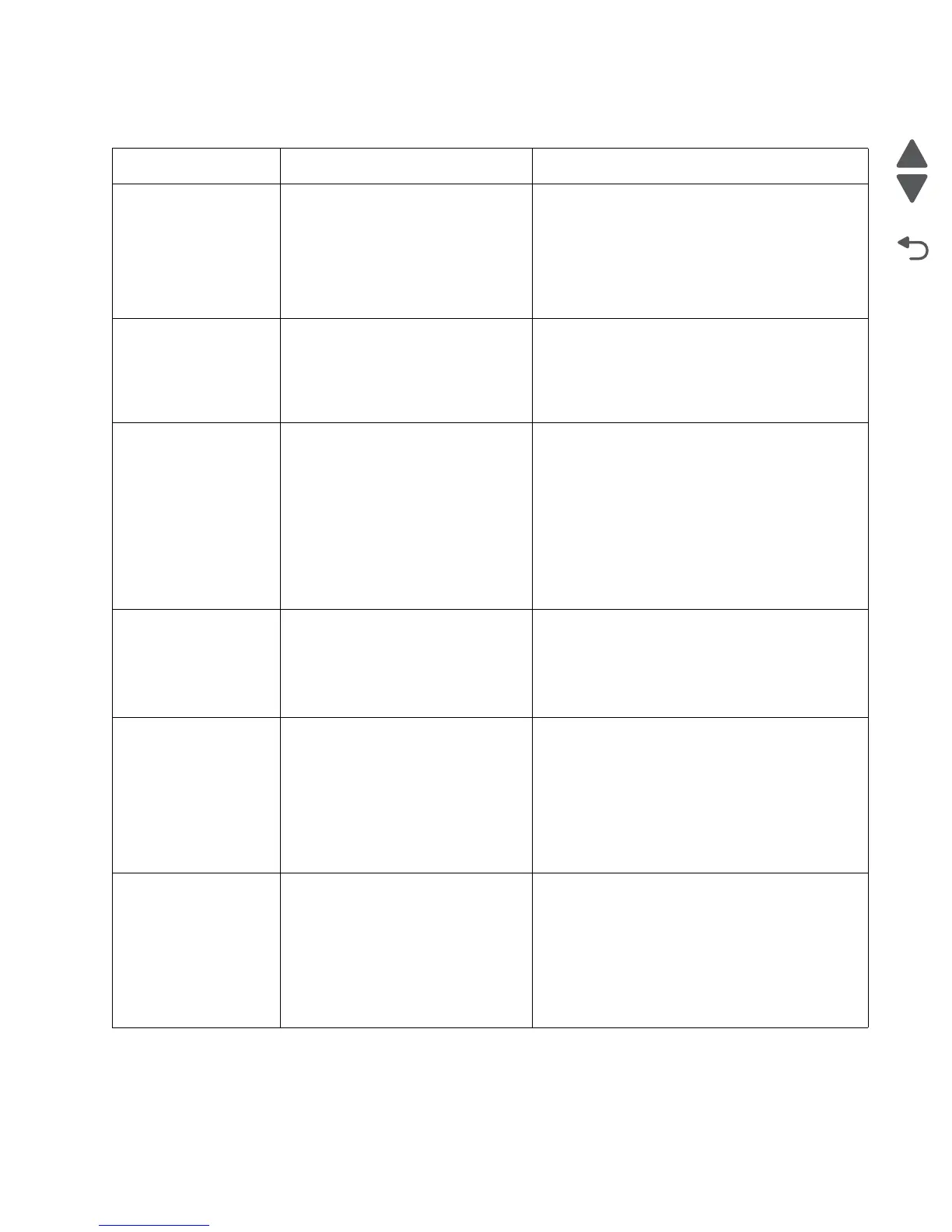

241.08 While feeding from tray 1, the S1

sensor does not break.

Possible causes:

• Incorrect media setting

• Incorrect paper loading

• Incorrect media restraint setting

• Paper pick mechanism failure

• Transport belt motor failure

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Flex the media, and stack it flat in the tray.

4. Properly set media restraints in the paper tray.

5. Check the pick arm rolls (tires) and replace if

worn.

Loading...

Loading...