Preventive maintenance 6-1

5062

6. Preventive maintenance

This chapter describes procedures for printer preventive maintenance. Follow these recommendations to help

prevent problems and maintain optimum performance.

Safety inspection guide

The purpose of this inspection guide is to aid you in identifying unsafe conditions.

If any unsafe conditions exist, find out how serious the hazard could be and if you can continue before you

correct the hazard.

Check the following items:

• Damaged, missing, or altered parts, especially in the area of the On/Off switch and the power supply

• Damaged, missing, or altered covers, especially in the area of the top cover and the power supply cover

• Possible safety exposure from any non-Lexmark attachments

Individual maintenance part expected life

Lubrication specifications

Lubricate only when parts are replaced or as needed, not on a scheduled basis. Use of lubricants other than

those specified can cause premature failure. Some unauthorized lubricants may chemically attack

polycarbonate parts.

The motor drive FRUs contain the proper lubricant in the FRU. Use only the lubricant included.

Lubrication for replacement motors

When you install a motor drive assembly, you must grease the posts and gears to ensure proper performance

from the printer.

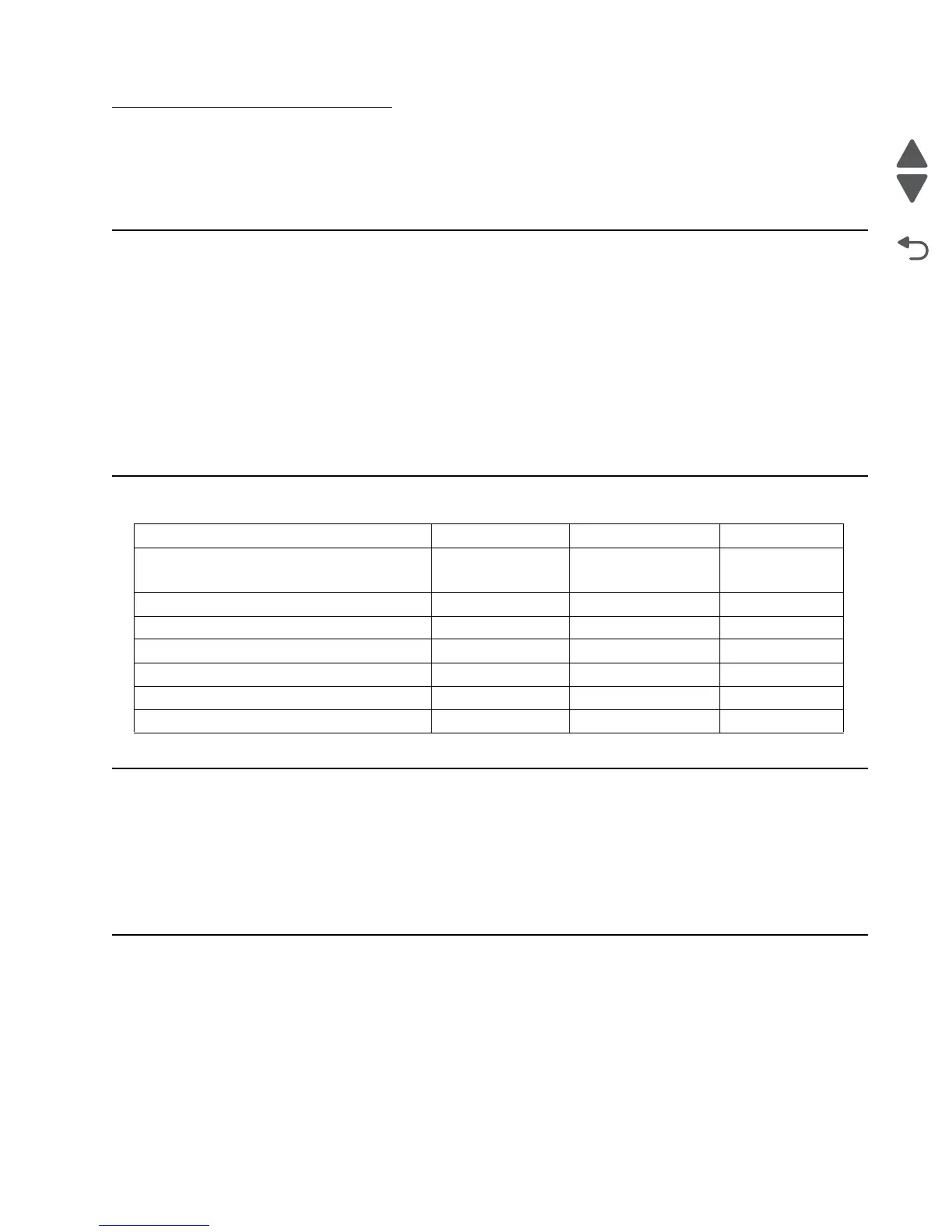

Description Part number Expected part life CRU/FRU

2000-sheet high-capacity feeder pick

roll assembly

40X6275 250K CRU

Fuser assembly, 115V 40X7100 150K CRU

Fuser assembly, 220V 40X7101 150K CRU

Fuser assembly, 100V 40X7102 150K CRU

ITU assembly 40X7103 200K CRU

MPF pick tires and wear parts 40X7178 15K FRU

Pick roll assembly 40X6104 250K FRU

Loading...

Loading...