Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 499

Appendix C Use Add-On Instructions

For example, to inhibit write commands from the device faceplate or other

external sources write a 1 to the ModuleName_AOI_CtlrSet.InhibitCmd

program tag from your application program. This write prevents a jog

command from the device faceplate.

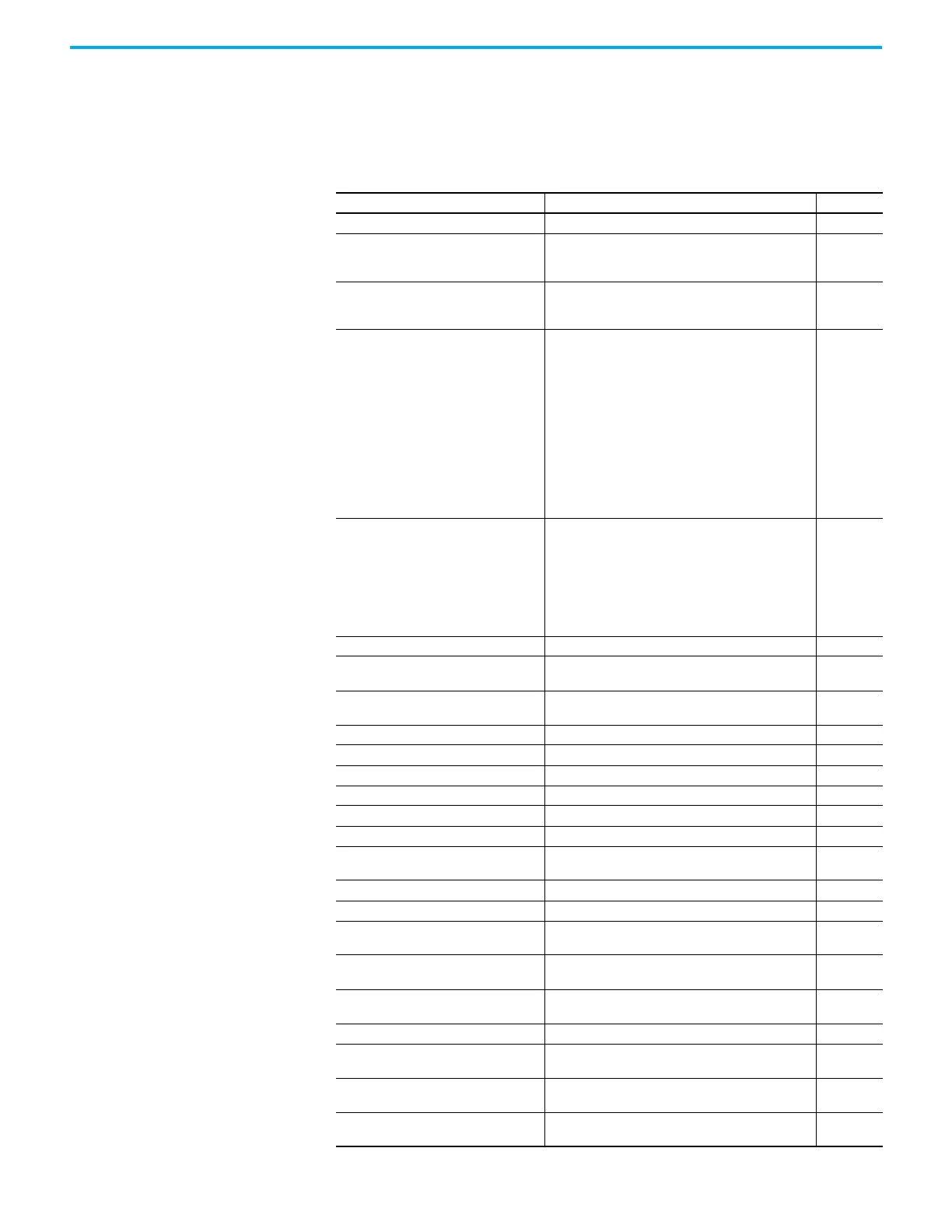

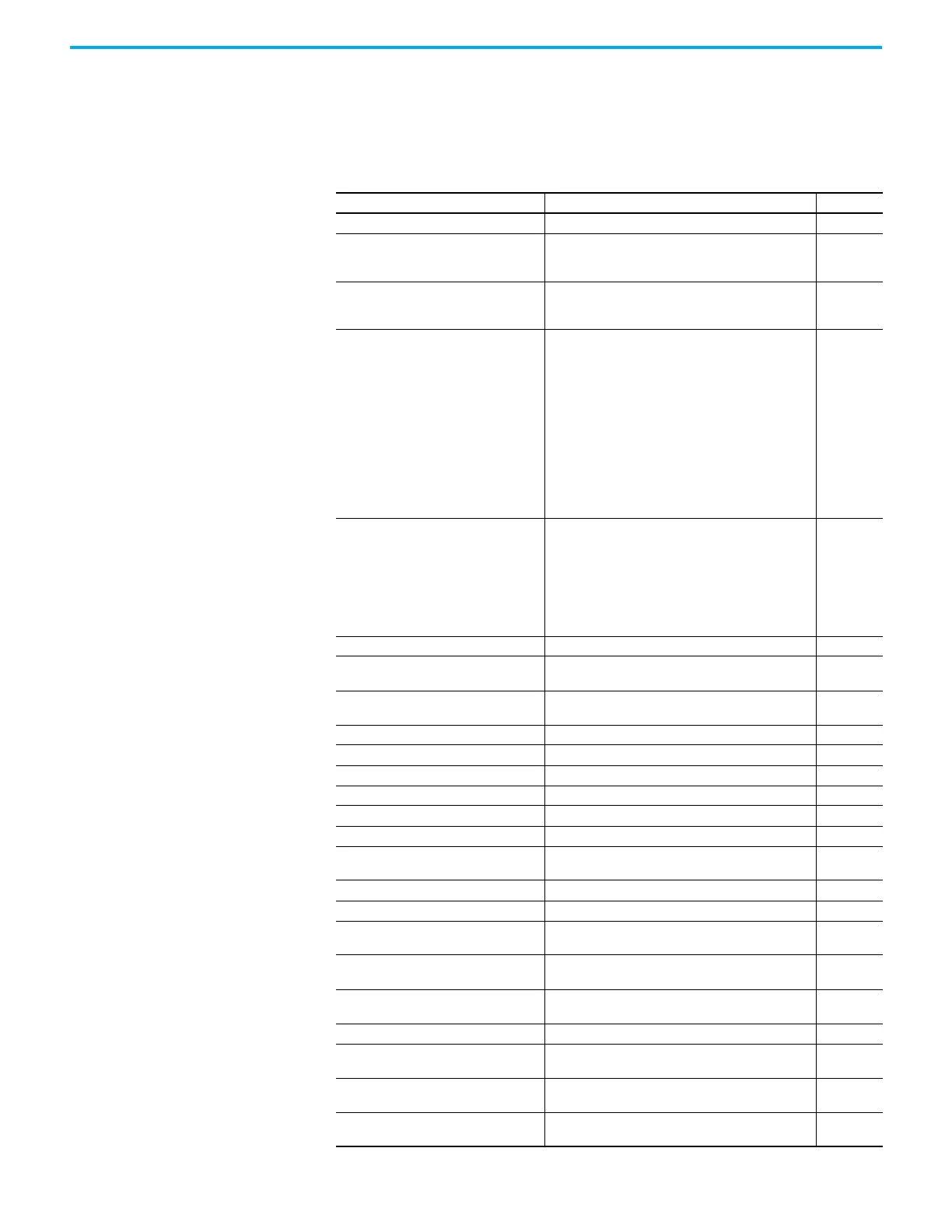

Table 153 - raC_UDT_Itf_K5100_Set Data Types

Member Description DataType

bInhibit Bit overlay for external access restriction DINT

InhibitCmd

1 = Inhibit user Commands from external sources; 0 =

Allow Control. This is only used with the optional device

faceplate.

BOOL

InhibitSet

1 = Inhibit user Settings from external sources; 0 = Allow

This member is only used with the optional device

faceplate.

BOOL

OperatingMode

Determines the drive operating mode when ‘Start

Motion’ has a zero-to-one transition.

1 - Position mode

2 - Speed mode

3 - Home mode

4 - Torque mode

5 - Gear mode (Fixed Ratio, based on present E-Gear

ratio)

6 - Index mode

7 - Reserved

8 - Gear Mode (Variable Ratio, based on Master/Slave

tag values)

9 - Enhanced MAT mode

DINT

MoveType

Specify the type of move.

0 = Absolute

1 = Incremental

2 = Rotary Shortest Path

3 = Rotary Positive

4 = Rotary Negative

7 = Relative

8 = Capture

DINT

PositionCommandOverlap Allows overlapping of successive movements. BOOL

PositionCommandOverride

Allows interruption of current movement, replacing it

with a new movement.

BOOL

CapturedPositionSelect

Capture position selection (First capture or second

capture).

BOOL

Position Determines the command position. REAL

Velocity Determines the command speed. REAL

Accel Determines the command acceleration. REAL

Decel Determines the command deceleration. REAL

Torque Determines the command torque. DINT

TorqueRampTime Determines the command torque ramp time. DINT

StartingIndex

This entry is the PR (Position Register) the drive should

execute.

DINT

HomingMethod Homing Method. DINT

HomeReturnSpeed Determines the command home return speed. REAL

CamMasterReference

Future: Determines the master position reference of

CAM.

DINT

CamExecutionSchedule

Future: Determines the method used to execute the CAM

profile.

DINT

CamExecutionMode

Future: Determines if the cam profile is executed only

one time or repeatedly.

DINT

CamStopMode Future: Determines the stop mode of CAM. BOOL

CamSlaveScaling

Future: Scales the total distance covered by the slave

axis through the cam profile.

DINT

CamLockPosition

Future: Determines the starting location in the cam

profile

DINT

CamMasterLockPosition

Future: Determines the master location where the slave

axis locks to the mater axis.

DINT

Loading...

Loading...