522 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Appendix C Use Add-On Instructions

raC_xxx_K5100_MAT

(1)

The Motion Axis Torque (raC_xxx_K5100_MAT) instruction lets you use torque

limiting while a pre-defined speed is used to move the motor. The first time the

pre-defined torque limit is reached, the Sts_TorqueReached bit is set. While

the Sts_TorqueReached bit is set, the MAT operation remains active until it is

terminated by an raC_xxx_K5100_MAS (Motion Axis Stop)/MSF (Motion Servo

Off), or a drive fault. The torque and speed entries are bi-directional.

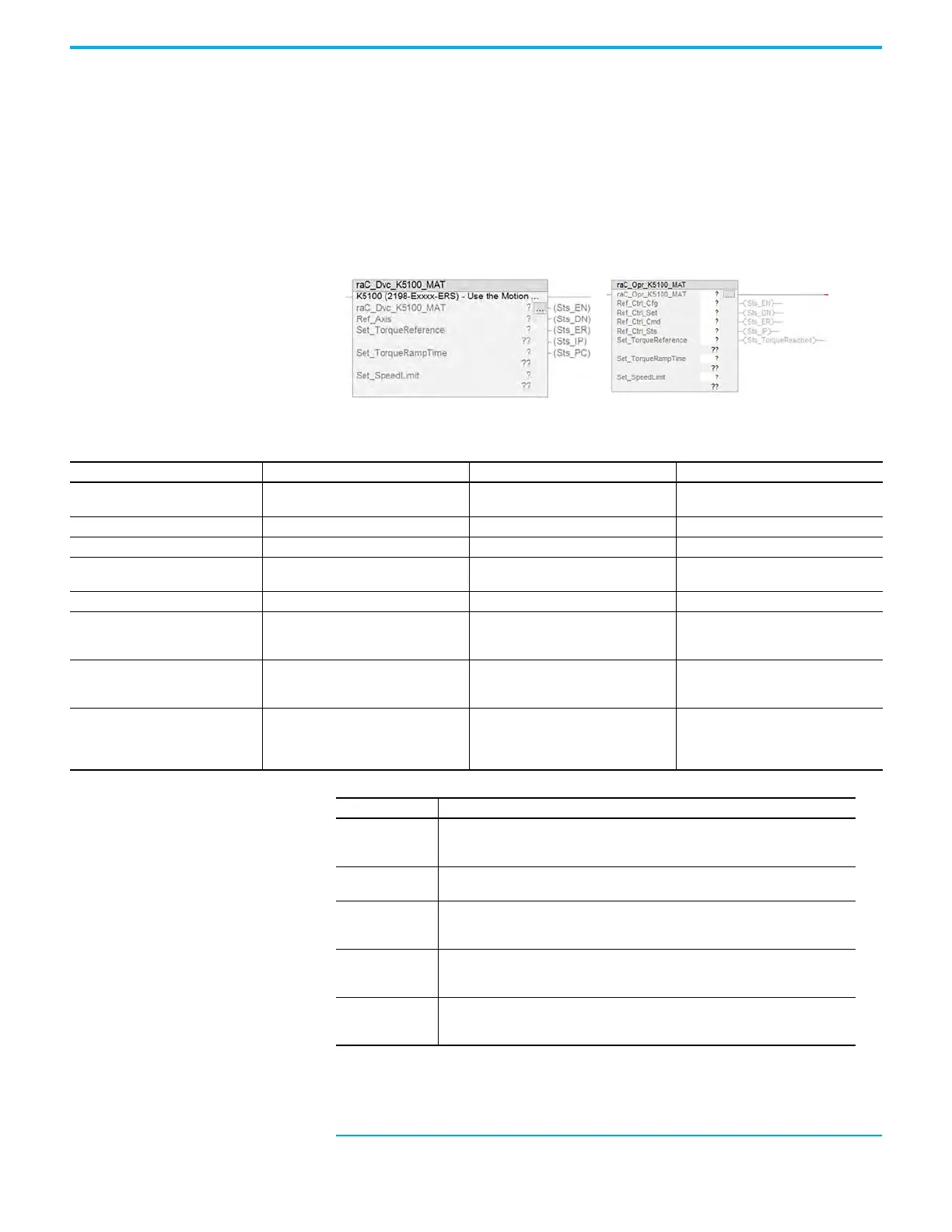

Figure 272 - MAT Ladder Diagram

Operands

(1) The xxx in the name can be Dvc (legacy applications) or Opr (new applications).

Operand Type Format Description

Instance raC_xxx_K5100_MAT Tag

Unique instance of the MAT Add-On

Instruction

Ref_Ctrl_Cfg raC_UDT_Itf_PowerMotionSA_Cfg Tag Interface for Ctrl_Cfg of the Device Object

Ref_Ctrl_Set raC_UDT_Itf_PowerMotionSA_Set Tag Interface for Ctrl_Set of the Device Object

Ref_Ctrl_Cmd raC_UDT_Itf_PowerMotionSA_Cmd Tag

Interface for Ctrl_Cmd of the Device

Object

Ref_Ctrl_Sts raC_UDT_Itf_PowerMotionSA_Sts Tag Interface for Ctrl_Sts of the Device Object

Set_TorqueReference DINT Immediate or Tag

The limited value of motor torque, in the

unit of 0.1% of the motor rated torque.

Range: -4000…+4000

Set_TorqueRampTime DINT Immediate or Tag

Torque Ramp Time, the time (ms) it takes

to ramp up from 0 to the

TorqueReference. Range: 1…65500

Set_Speedlimit REAL Immediate or Tag

Speed limit that is used during the

constant torque operation: unit is 0.1 rpm

for rotary motor. Range: -

80,000…+80,000

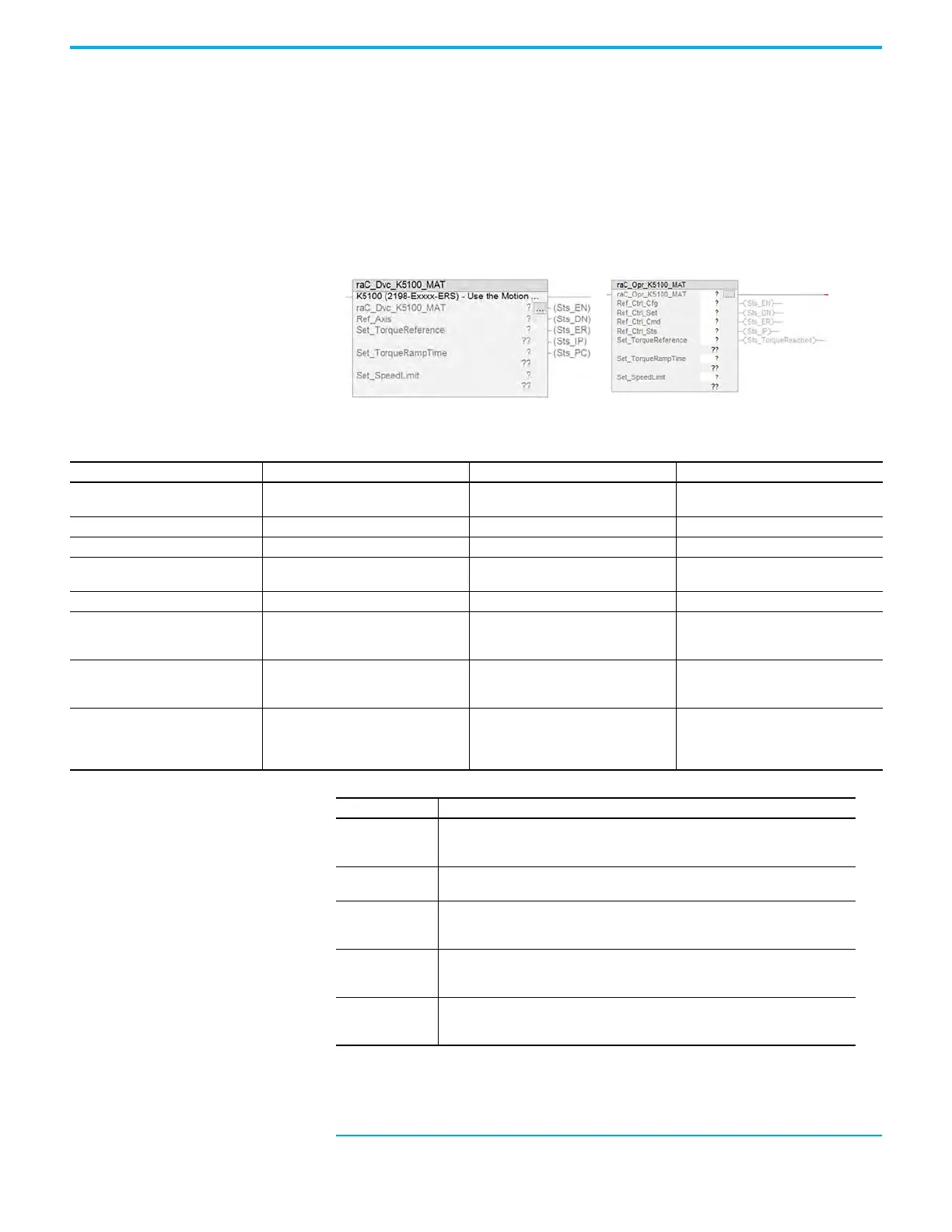

Mnemonic Description

Sts_EN (Enable)

This bit is set when the rung makes a false-to-true transition and remains set as the

message transaction to execute the MAT is initiated and in process. It remains high

until the rung-in condition is false and no faults are active.

Sts_DN (Done)

This bit is set when the rung makes a false-to-true transition and the message

transaction to the drive (Sts_EN) is complete.

Sts_ER (Error)

This bit is set when the rung makes a false-to-true transition and there is an error that

has occurred with the instruction. (This instruction error can be a result of a fault on

the drive itself). See Sts_ERR for details on the cause of the error.

Sts_IP (In Progress)

This bit is set when the rung makes a false-to-true transition, the MAT message

transaction is successful, and the motor begins to move. This bit remains set while the

MAT operation is active.

Sts_PC (Process

Completed)/

Sts.TorqueReached

This bit is set when the rung makes a false-to-true transition, the Sts_IP is set, and the

Set_TorqueReference value is reached. This bit is set (and remains set) on the first

occurrence of this condition.

Loading...

Loading...