384 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Chapter 12 Motion Control Applications

E-CAM The Kinetix 5100 drive has an electronic camming feature. Position cams, in

effect, provide the capability of implementing non-linear electronic gearing

relationships between the Kinetix 5100 motor (slave) and a master device

(another drive, encoder, or time). No maximum velocity, acceleration, or

deceleration limits are used.

The motion of the master device and the designated cam profile that is derived

from the associated cam table determine the speed, acceleration, and

deceleration of the slave axis.

The E-CAM feature executes a position cam that is created by a user-defined

profile in the KNX5100C software or directly from the user-defined data array.

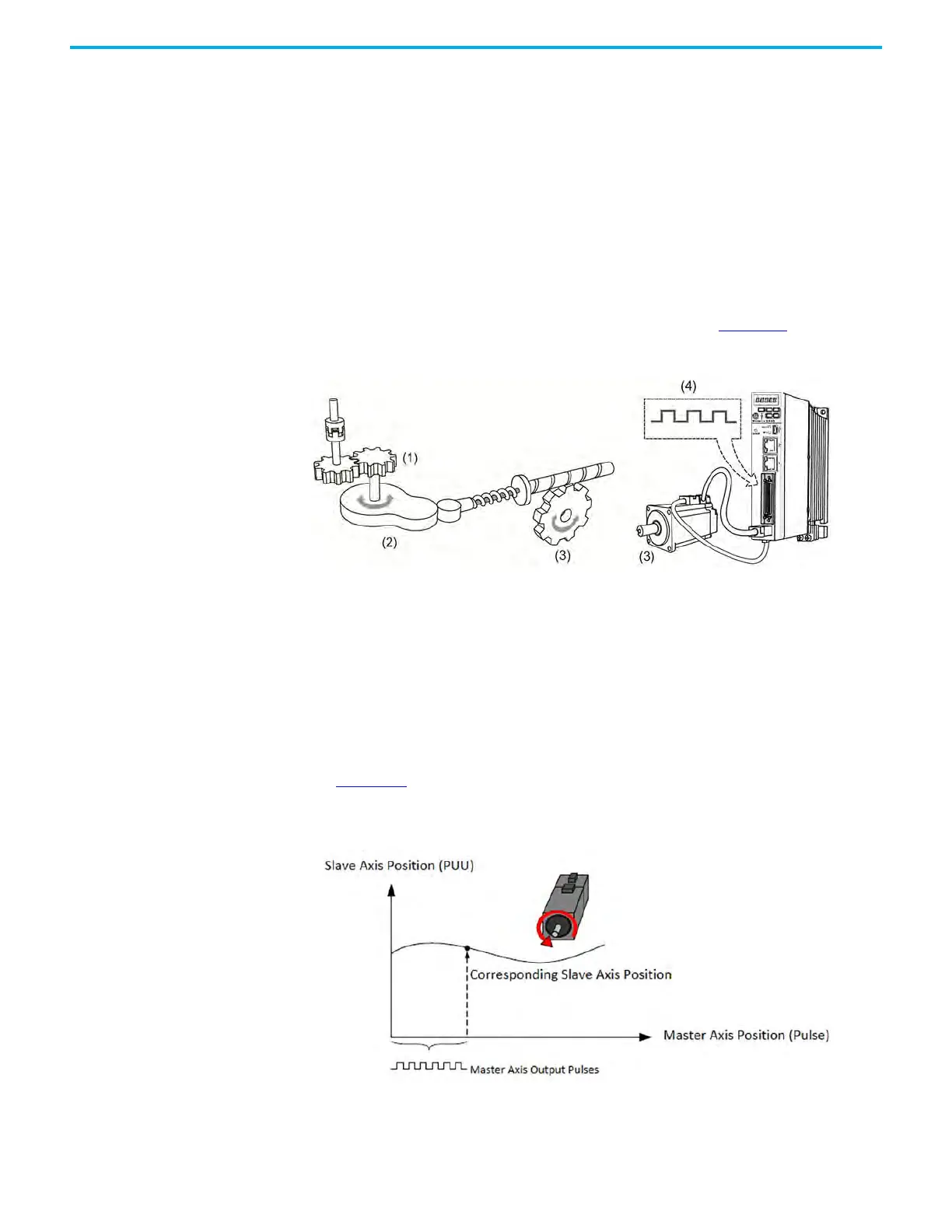

The mechanical cam and electric cam are illustrated in Figure 191

.

Figure 191 - Mechanical Cam and E-CAME-CAM

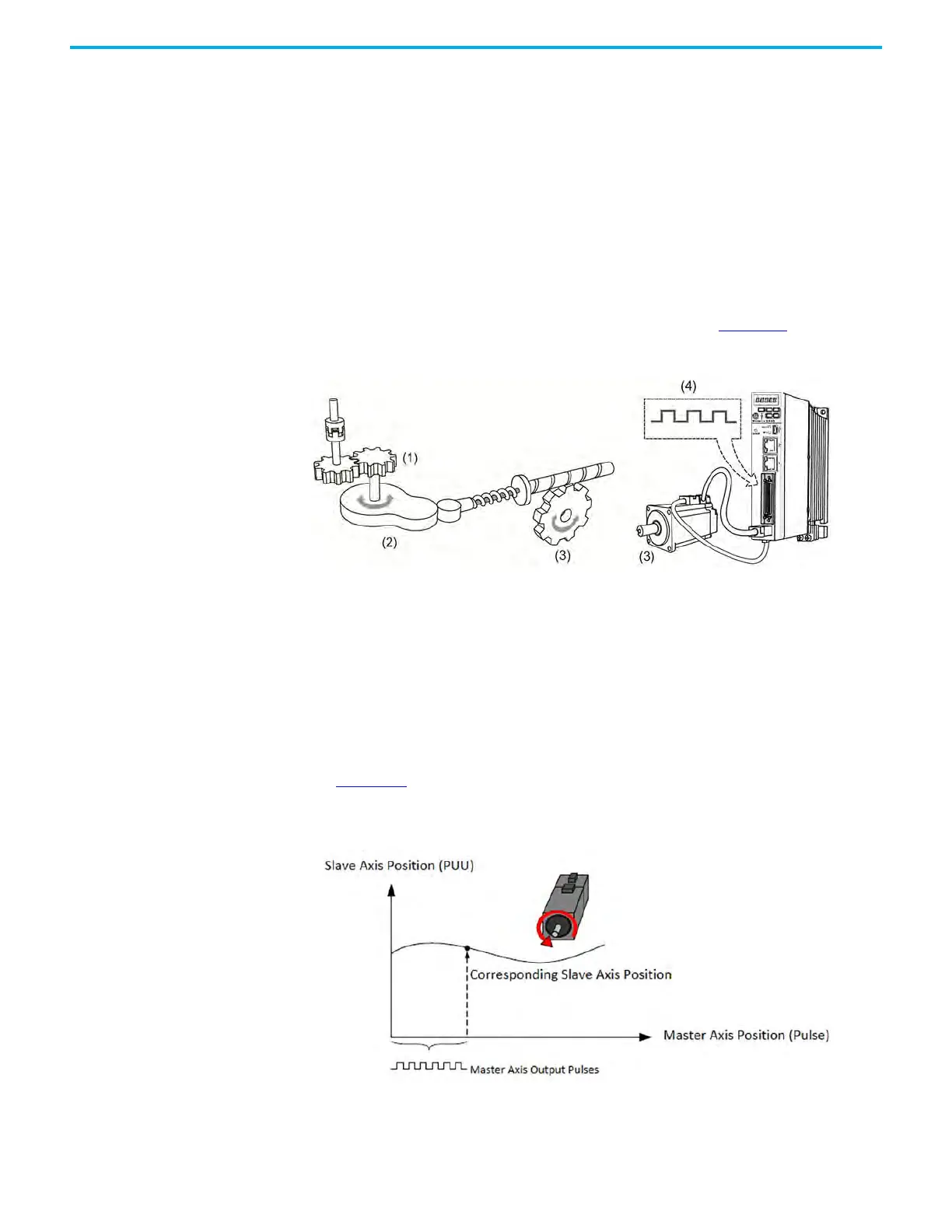

The E-CAM function can be used only in PR Operating mode. After the E-CAM

engagment conditions are met and the E-CAM is active, the slave axis follows

the pre-defined cam profile, and the position of the slave axis is a function of

the master position (or time). As a result of master movement, pulses are

created. Those master pulses are used as the reference for the slave to follow;

and the slave follows those pulses based on its pre-defined profile, shown in

Figure 192

. The E-CAM function can be enabled or disable by setting parameter

ID376 (P5.088.X).

Figure 192 - E-CAM Curve

(1) - Master Axis Input and Gear

(2) - Mechanical Cam

(3) - Slave Axis Output

(4) - Master Axis Input for E-CAM

Loading...

Loading...