Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 385

Chapter 12 Motion Control Applications

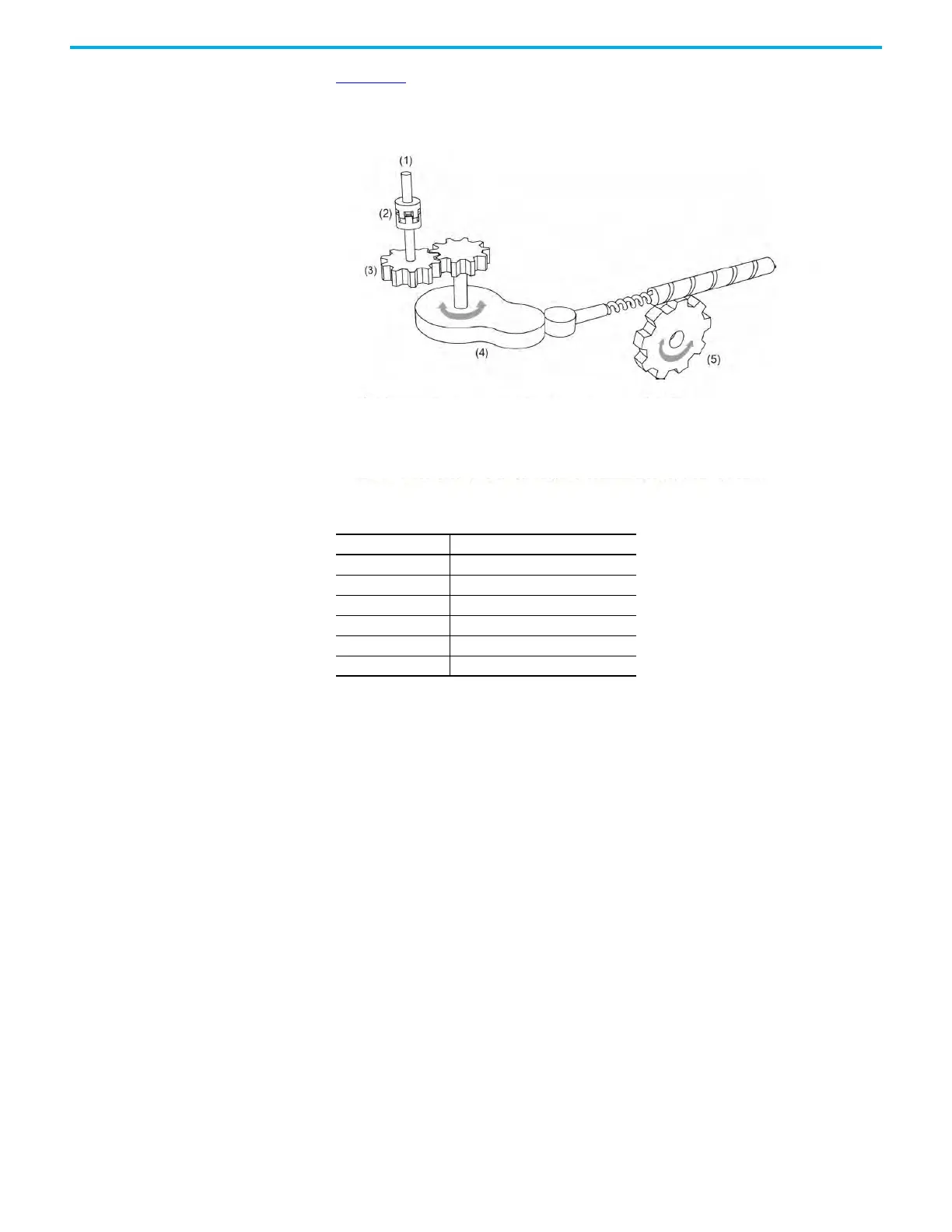

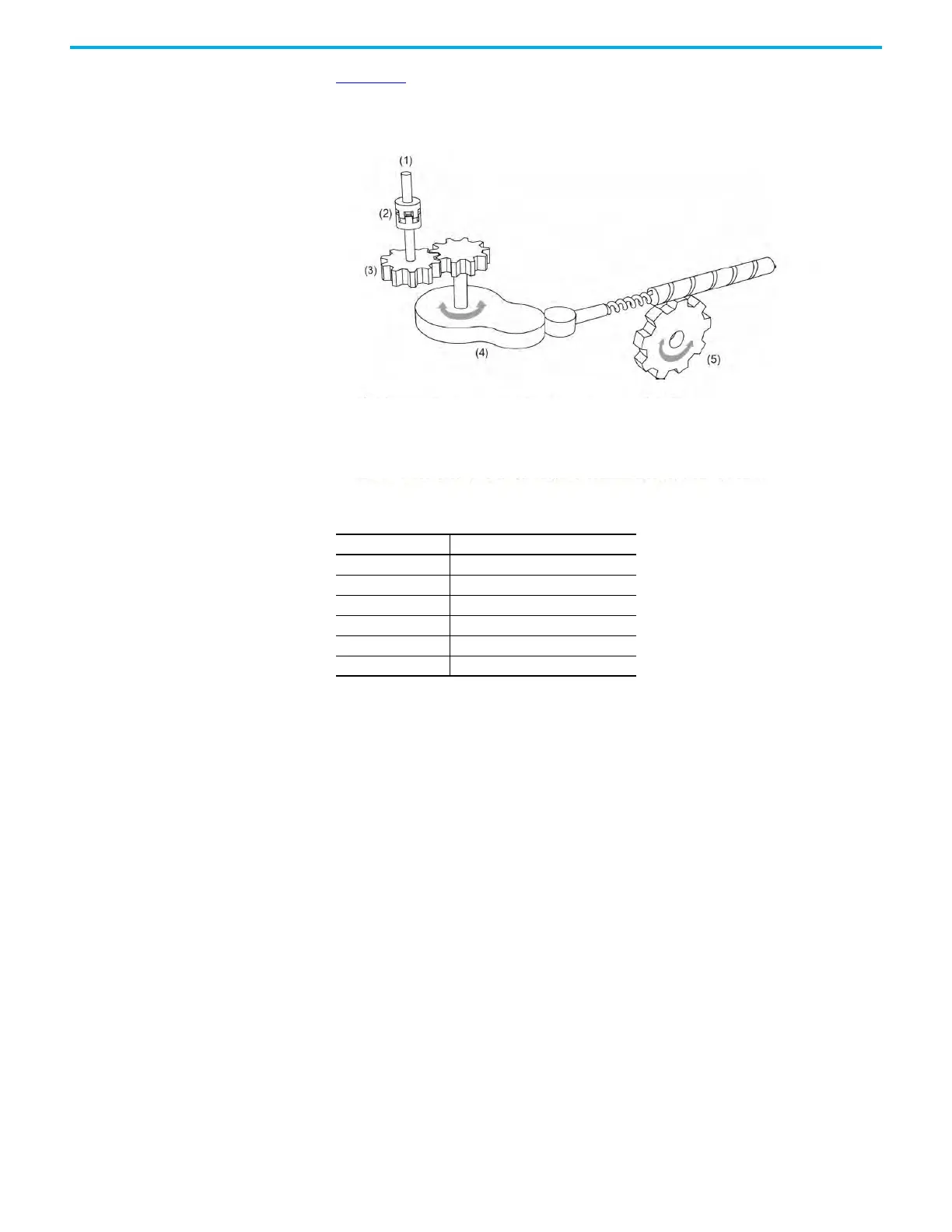

Figure 193 uses the mechanical cam concept to illustrate the E-CAM parameter

settings.

Figure 193 - Electronic cam simulates mechanical cam assembly with servo drive parameters

(1) Master Axis: master axis signal source is set by ID376 (P5.088.Y)

(2) Clutch: time to engage or disengage is set by ID376 (P5.088.UZ), ID375 (P5.087), ID377 (P5.089)

(3) Master Axis Gear Ratio: pulse input resolution is set by ID371 (P5.083), ID372 (P5.084)

(4) E-CAM Curve: curve is set by ID369 (P5.081), ID370 (P5.082), ID373 (P5.085), scale is set by ID311 (P5.019)

(5) Slave Axis Gear Ratio: output signal resolution is set by ID151 (P1.044), ID152 (P1.045)

Table 121 - E-CAM General Settings

Parameter Name

ID245 (P2.073) ECamConfiguration

ID246 (P2.074) ECamDIDelayTimeCompensation

ID247 (P2.075) ECamAlignementTargetPosition

ID248 (P2.076) ECamControlConfiguration

ID249 (P2.078) ECAMDOCamArea_RisingEdge

ID250 (P2.079) ECAMDOCamArea_FallingEdge

Loading...

Loading...