Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 375

Chapter 12 Motion Control Applications

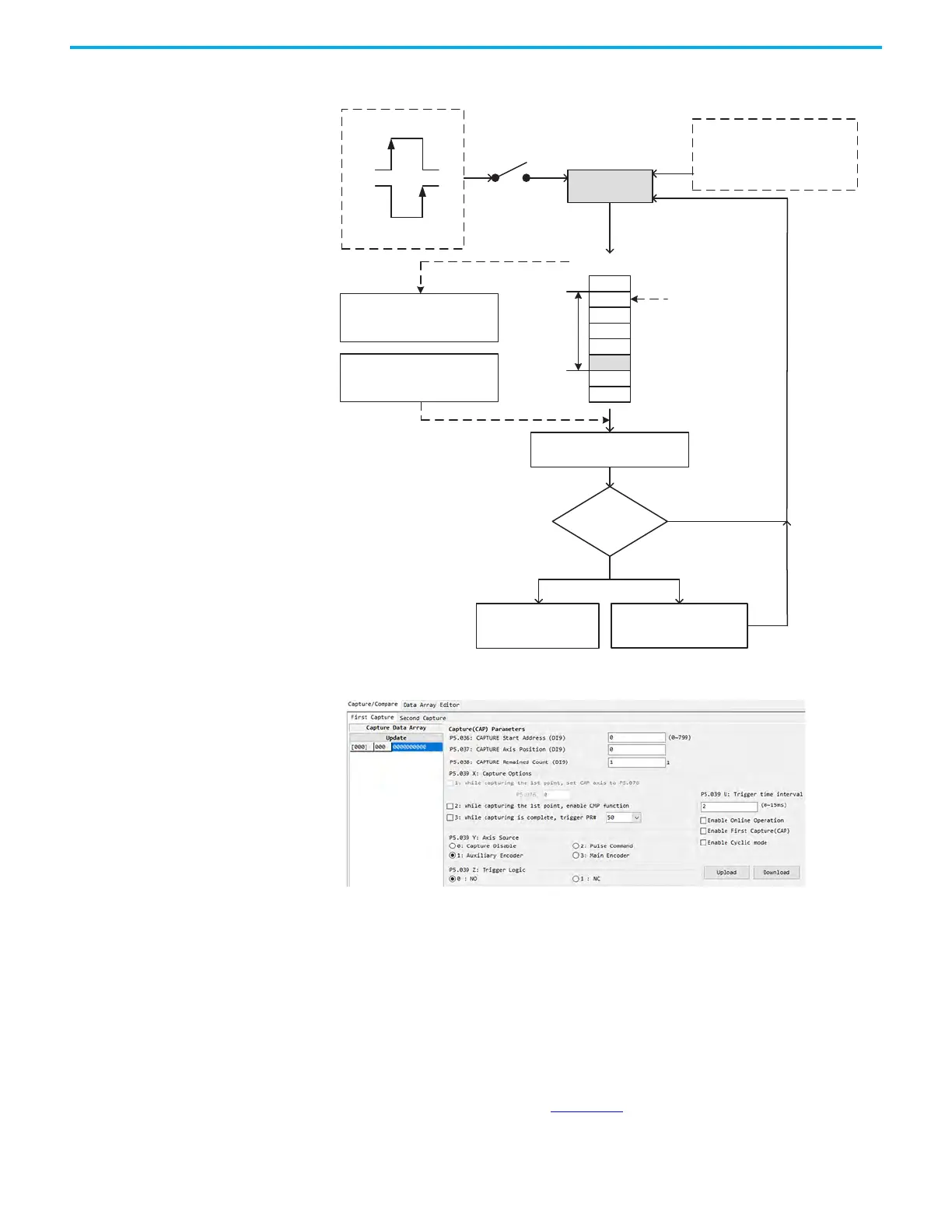

Figure 182 - High-speed Position Capture Flowchart (DI9 example)

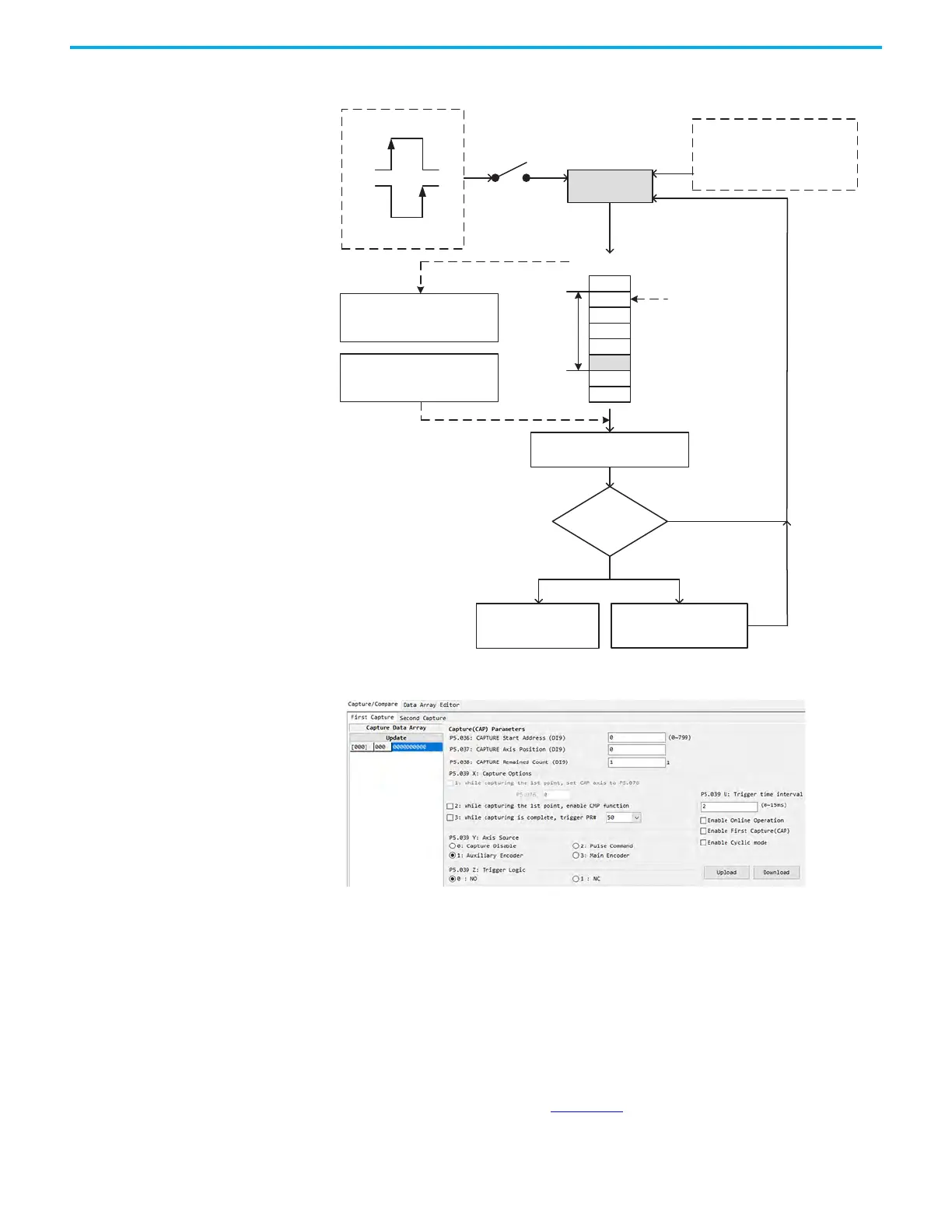

Figure 183 - Capture Function Screen

Using PR Command Programming with the Capture Function

You can use KNX5100C software to configure the Capture function. However,

if the functions must change while the application is running, you can use

PR Write command to change it.

With PR write command programming, write commands configure the high-

speed position capture function, as well as execute the motion commands once

configuration is complete. See Chapter 11

for details on PR command

programming.

CAP Axis Source

Normally Open

ID331 (P5.039.Z) = 0

DI9

Normally Closed

ID331 (P5.039.Z) = 1

DI9

CAP Switch

ID331 (P5.039.X) Bit 0

CAP Axis

Position

ID329 (P5.037)

7890

CAP Axis Source

Aux Encoder ID331 (P5.039.Y) = 1

Pulse Command ID331 (P5.039.Y) = 2

Main Encoder ID331 (P5.039.Y) = 3

Data Array

Reset the First Position

ID331 (P5.039.X) Bit 1 = 1

First Position = ID368 (P5.076)

Enable CMP after the

first data is captured.

ID331 (P5.039.X) Bit 2 = 1

CAP Amount

ID330 (P5.038)

Start Address

ID328 (P5.036)

CAP Amount

ID330 (P5.038) = ID330 (P5.038) - 1

CAP Completed?

ID330 (P5.038) = 0

No

Yes

Call PR#50

ID331 (P5.039.X) Bit 3 = 1

Cyclic CAP ID131 (P1.019.X) = 1

ID330 (P5.038) = Previous

Setting Value

1234

2345

5678

6789

7890

Loading...

Loading...