400 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Chapter 12 Motion Control Applications

E-CAM Profile Types

The electronic cam profile is a variable relationship between a master and slave

signal. The cam profile can be built in a variety of ways and can be built using

other mathematical software tools. The KNX5100C software uses the E-CAM

editor to create and edit different types of profiles. Once the profile is created,

it is stored in the Data Array. The following are some important

considerations:

• One single profile can have up to 720 points.

• The Master data must all be within a value of 360. It is typical to think of

this value as degrees because the drive does not use Position Units as

scaling. This value can later be normalized in the E-CAM configuration to

match your application, for example, pulses required for one machine

cycle.

• The master data is not changeable when it is entered into the data table

and is evenly spaced depending on the amount of points that are

entered.

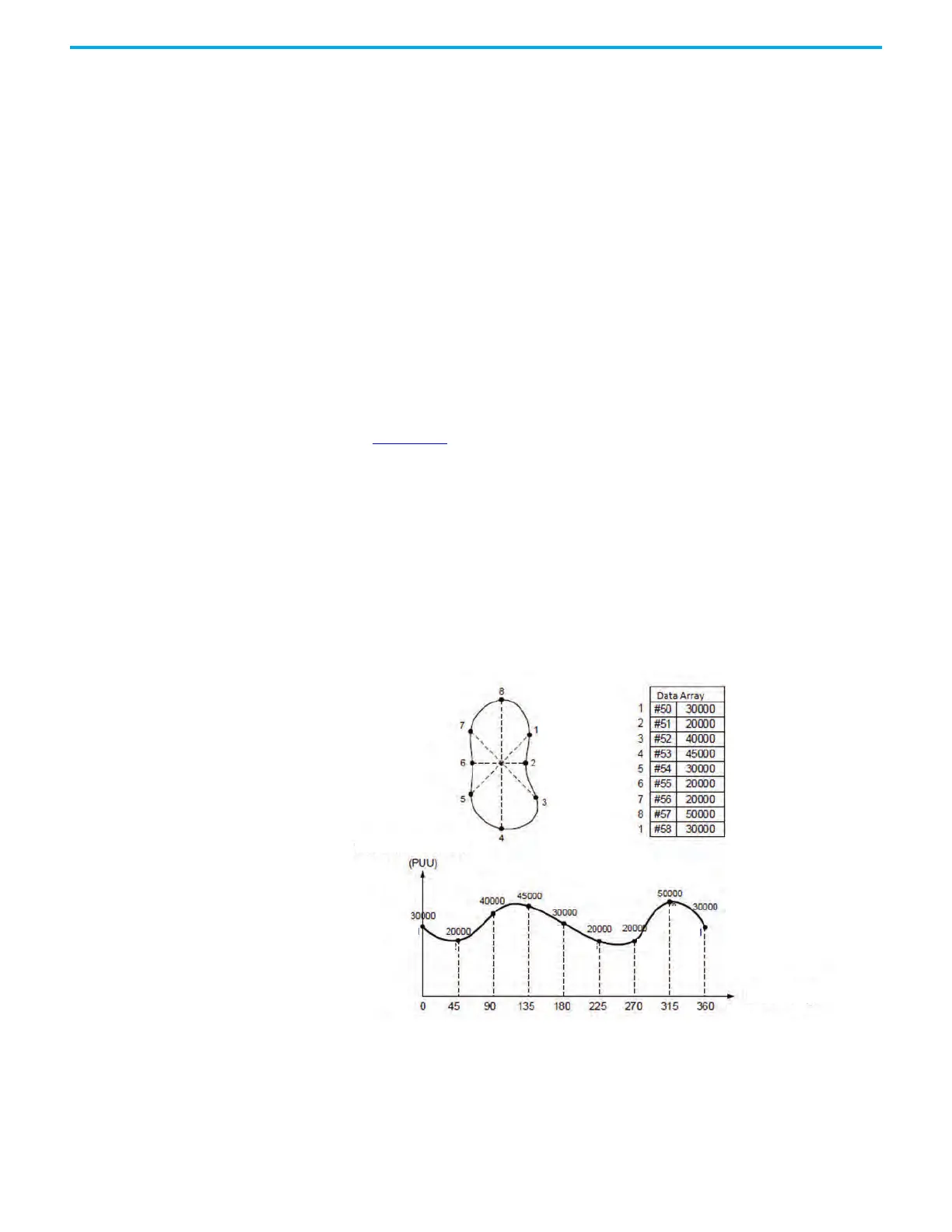

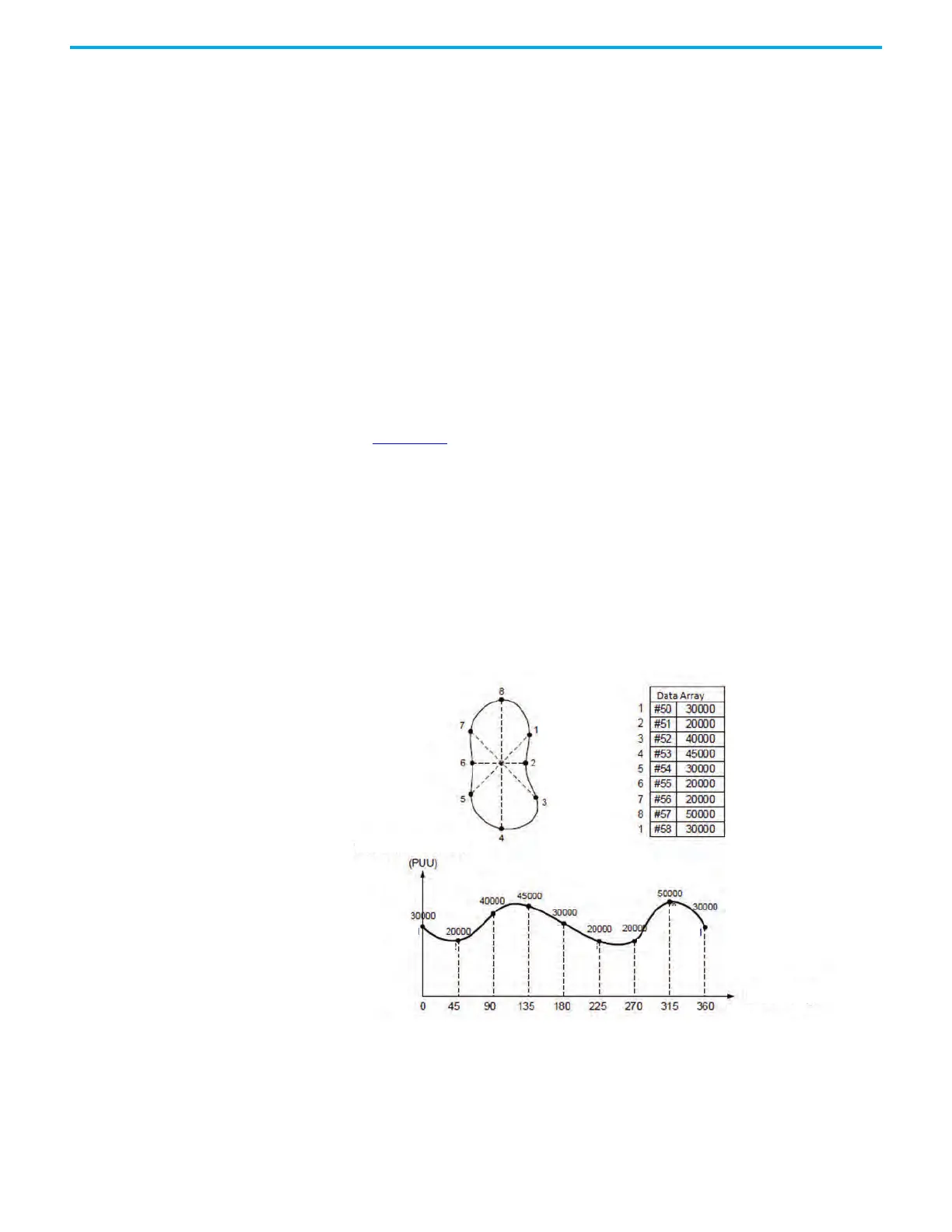

Take Figure 209

as an example, if a mechanical cam is to be replaced by an

electronic cam, the mechanical cam must be divided into several equal parts.

The more granular the divisions, the higher the accuracy. This example divides

it into 8 equal parts. Each part is separated by 45 degrees (for example, the

actual application may have finer definition (and granularity). The starting

point of 0 degrees and the last point of 360 degrees is the same point. It is

typical for these points to be used to define an entire machine cycle. Therefore,

a total of 9 point pairs of data must be filled in to create the table of the

electronic cam curve.

Figure 209 - E-CAM Curve Table Creation

E-CAM angle °

Slave Axis Position

1

2

3

4

5

6

7

8

9

Loading...

Loading...