Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 401

Chapter 12 Motion Control Applications

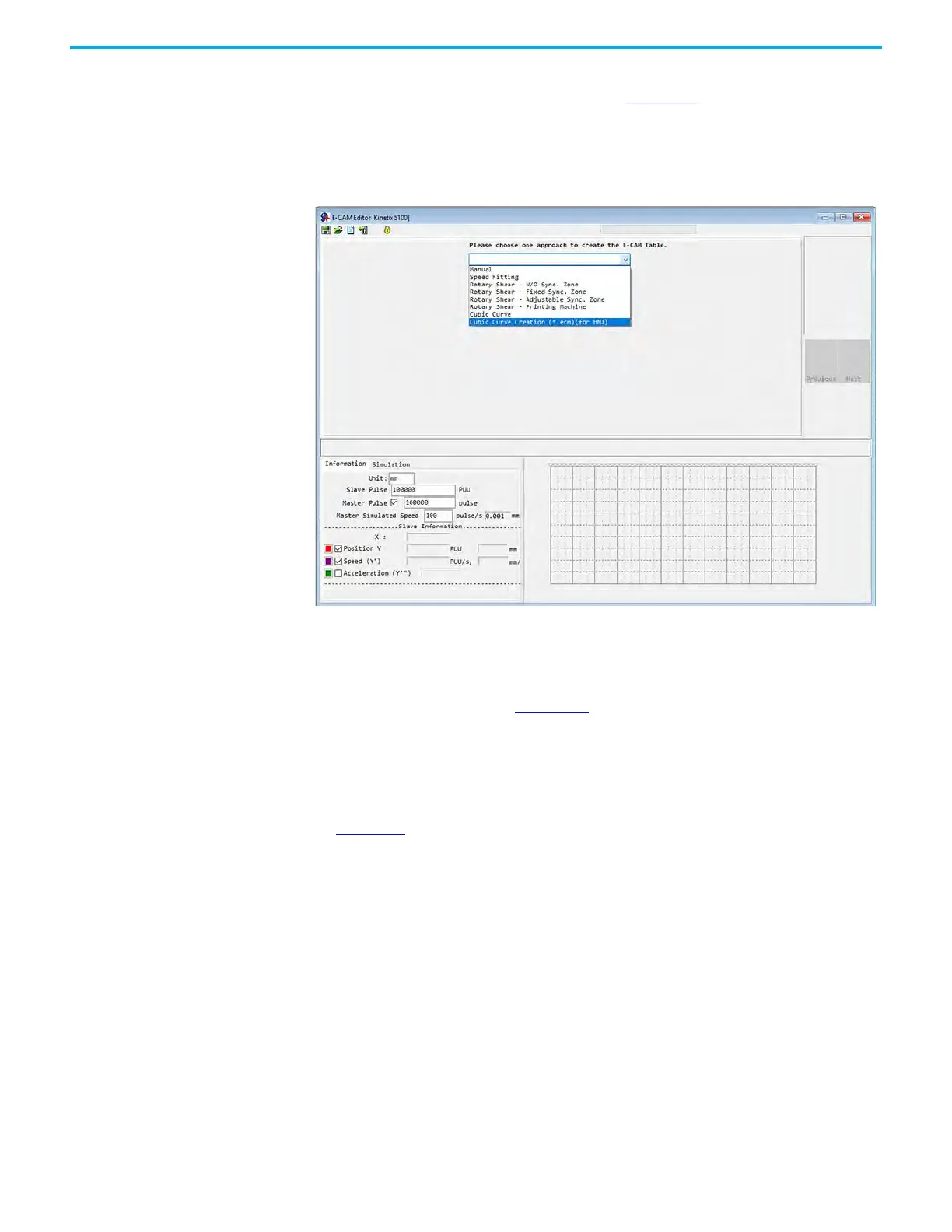

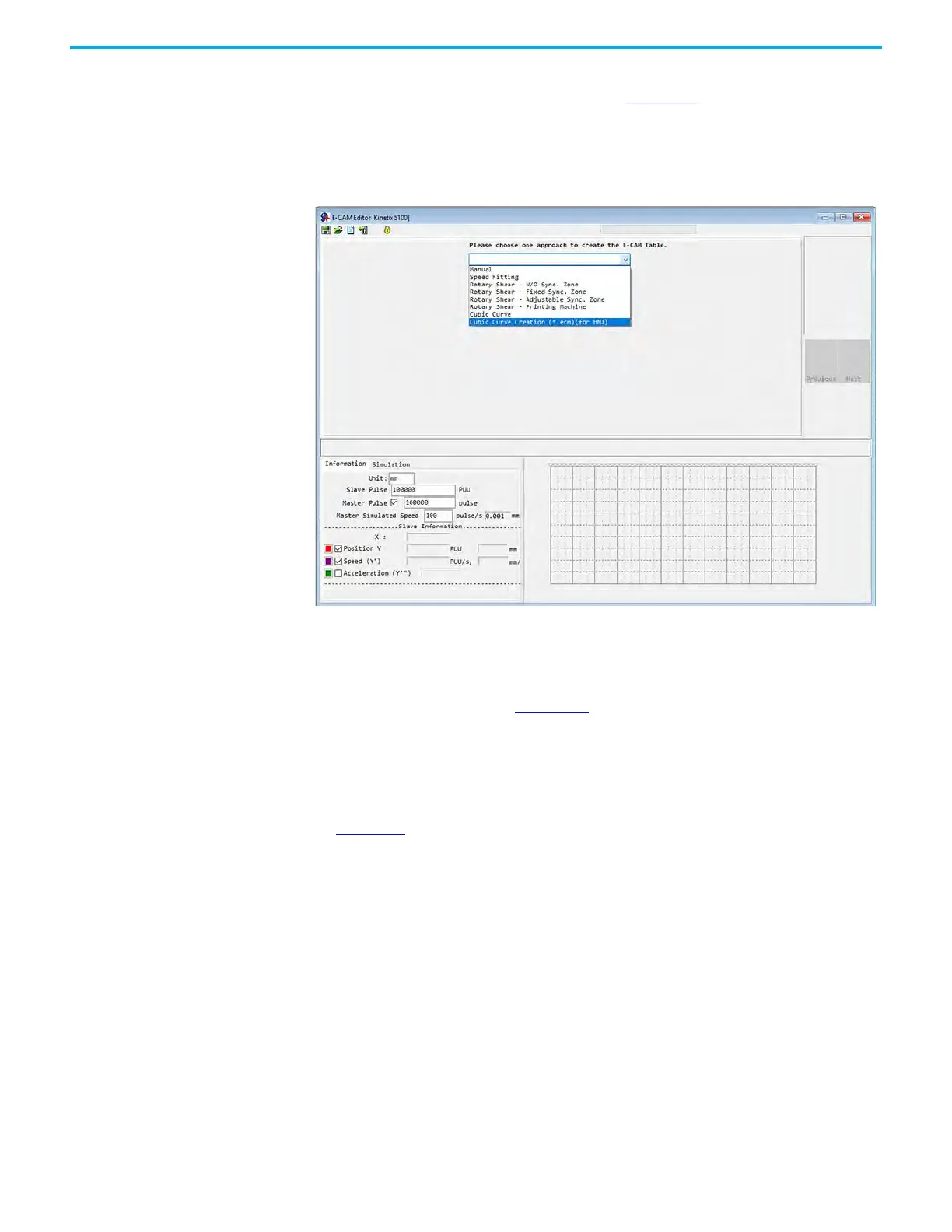

You can use KNX5100C software to create electronic cam curves. Navigate to

Motion Control>E-CAM editor, shown in Figure 210

.

The E-CAM editor contains a wizard that uses 4 steps to complete the E-CAM

configuration. Step 1 is used to choose the approach to use for your E-CAM.

Figure 210 - E-CAM Edit Dialog Box

Manual

If the E-CAM table is already known, you can enter the points to complete the

cycle profile. As shown in Figure 209

, the E-CAM curve is created based on the

cam curve-to-edge distance corresponding to each angle of the mechanical

cam, which is relationship between the angle and the slave axis position. You

must use your master machine cycle profile as degrees. These values can be

normalized back into counts in the E-CAM editor Parameter Setting Step. The

KNX5100C software E-CAM table manual creation interface is shown in

Figure 211

. The following are the steps to manually create the table:

1. Set the number of E-CAM segments.

A single cam can be divided into up to a maximum of 720 segments (721

points). For a period of 360 degrees, every 0.5 degrees corresponds to a

slave axis position. The more points, the higher the resolution. To select

the most suitable number of segments, consider the resolution of the

curve and the resource usage of the data array.

Loading...

Loading...