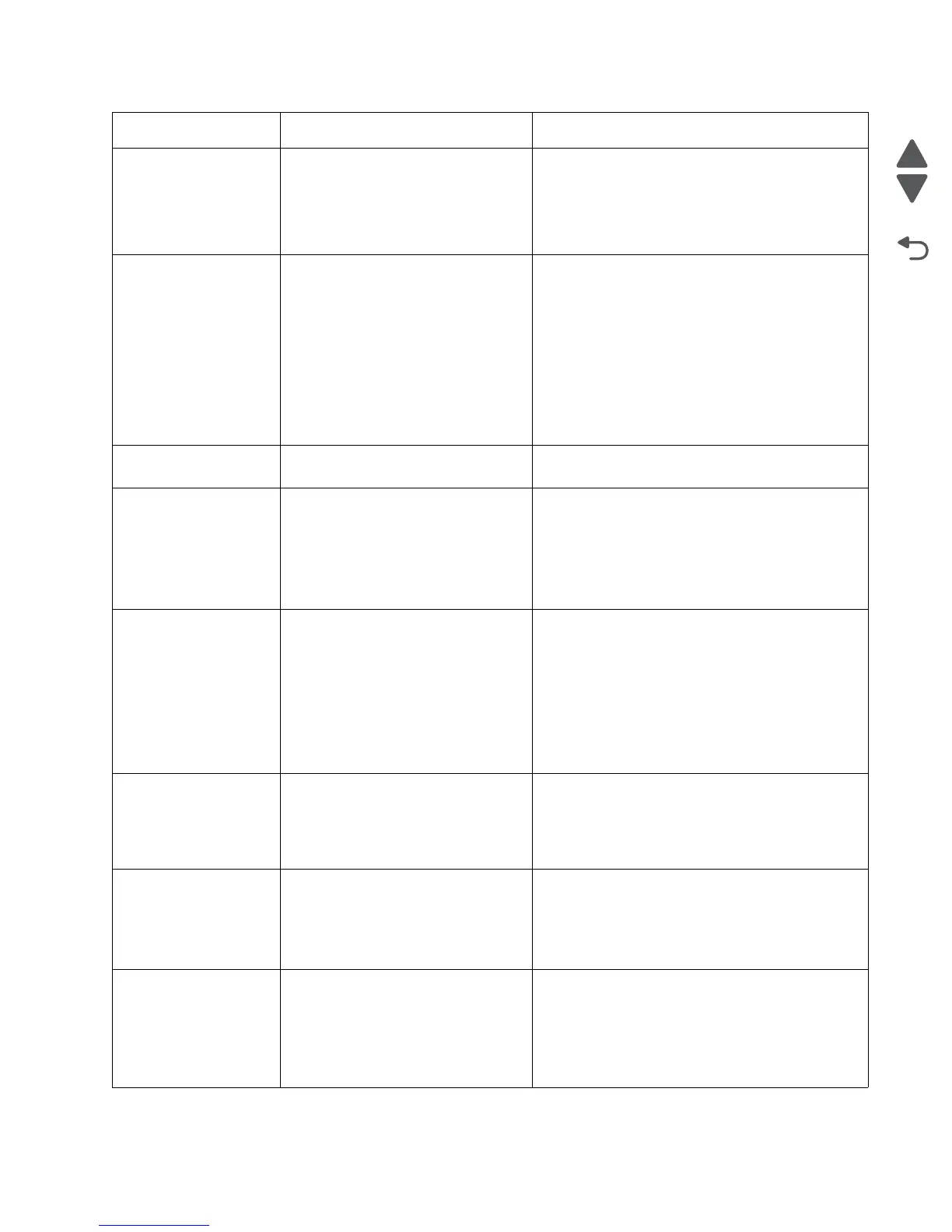

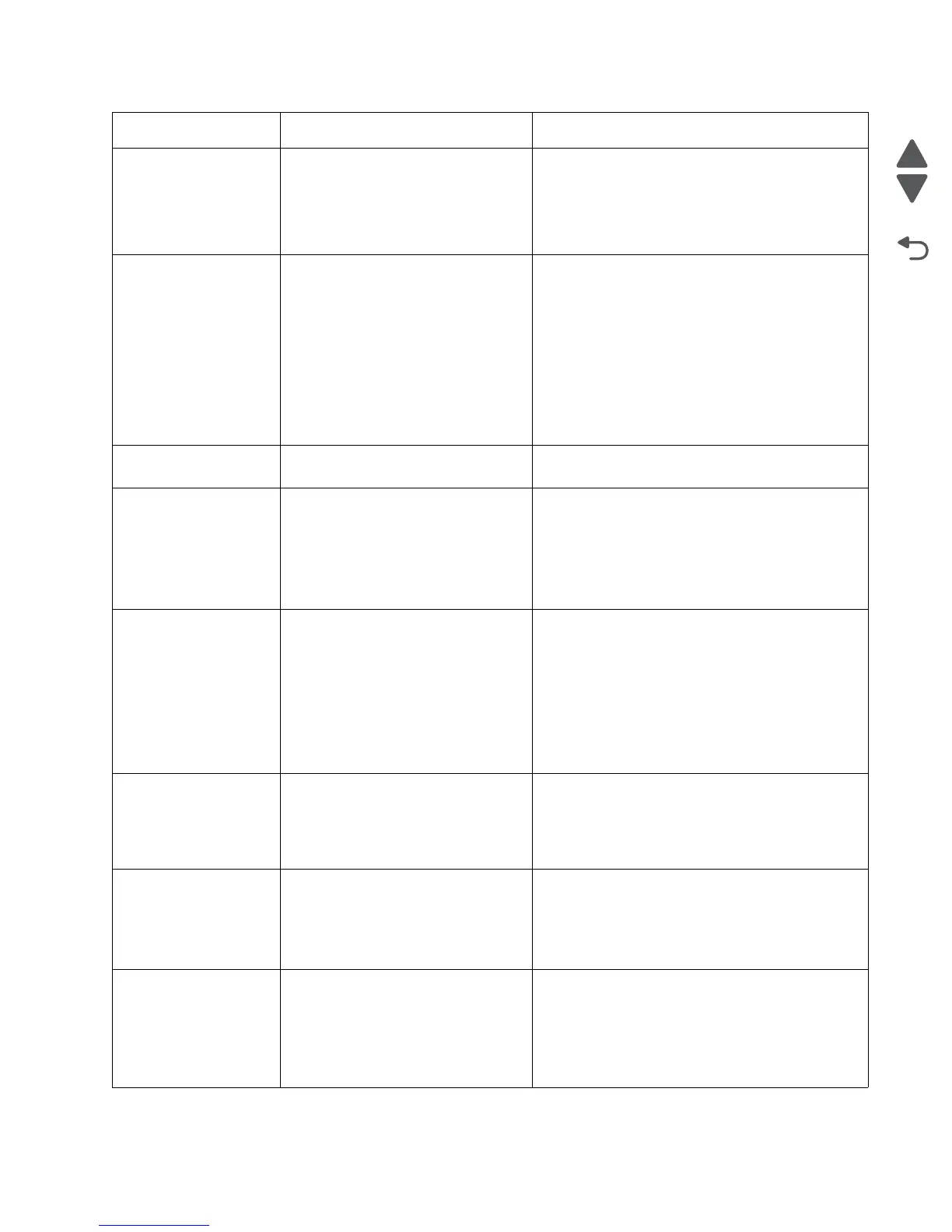

Diagnostic information 2-5

5062

200.04 Input sensor flag broke early.

Possible cause:

• Incorrect paper settings

• Faulty input sensor

• Faulty system board

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Go to “Input, S1, narrow media, and near

narrow media sensor service check” on

page 2-153.

200.05,

200.07

Input sensor does not break or breaks

late.

Possible causes:

• Incorrect paper settings

• Incorrect paper loading

• Incorrect paper guide setting

• ITU module failure

• Lower guide failure

• Paper pick mechanism failure

• Input sensor failure

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Flex the media, and stack it flat in the paper tray.

4. Properly set the paper guides in the paper tray.

5. Check the pick roll tires, and replace them if they

are worn.

6. Go to “200.05, 200.07—Paper Jam error

service check” on page 2-96.

200.08 Input sensor is never made or made

late.

See “200.03” on page 2-4.

200.21,

200.22

Staging motor stalled or is under

speed.

Possible causes:

• Faulty staging motor

• Faulty cable/connector

• Faulty system board

1. Check that the waste toner container is latched

correctly in the printer.

2. Check for anything in the paper path that might

cause the paper to jam.

3. If clearing a paper jam does not fix the problem,

go to “147.xx—Staging motor error service

check” on page 2-87.

200.31 Near narrow media sensor is made

when the printer tries to print from an

idle state.

Possible causes:

• Paper jam leaving paper over the

sensor

• Defective near narrow media

sensor

• Faulty system board

1. Clear away anything in the paper path that might

cause the paper to jam.

2. If clearing a paper jam does not fix the problem,

go to “Input, S1, narrow media, and near

narrow media sensor service check” on

page 2-153.

200.32 Near narrow media sensor is never

made or is made late.

• Damaged narrow media flag or

narrow media sensor

• Loose input sensor

1. Clear away anything in the paper path that might

cause the paper to jam.

2. If clearing a paper jam does not fix the problem,

go to “200.32—Paper Jam error service

check” on page 2-98.

200.33 Near narrow media sensor is never

made or is made late.

• Faulty input sensor

• Faulty staging deflector assembly

• Faulty autocomp assembly

1. Clear away anything in the paper path that might

cause the paper to jam.

2. If clearing a paper jam does not fix the problem,

go to “200.33, 200.38—Paper Jam error

service check” on page 2-99.

200.34 Near narrow media sensor broke

early.

Possible causes:

• Incorrect paper settings

• Defective near narrow media

sensor

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Go to “Input, S1, narrow media, and near

narrow media sensor service check” on

page 2-153.

Error code Description Action

Loading...

Loading...