2-10 Service Manual

5062

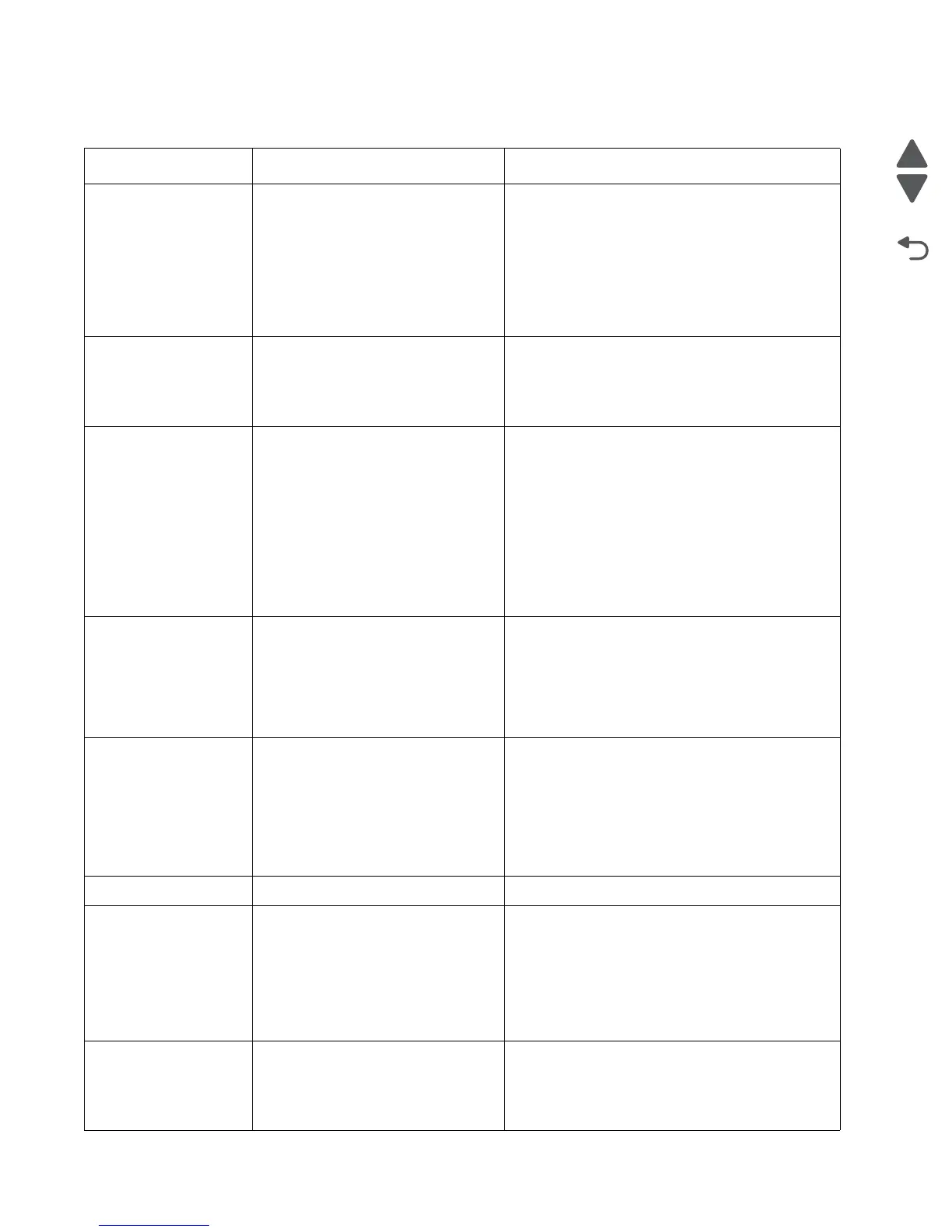

Additional checks—202–203 paper jams

Error code Description Action

202.01 Exit sensor is made when printer tries

to print from an idle state.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Damaged fuser autoconnect

• Faulty fuser

• Faulty system board

1. Check for anything in the paper path that might

cause the paper to jam.

2. The fuser exit sensor may not be functioning

properly. Go to “121.xx—Fuser error service

check” on page 2-70.

202.02 Exit sensor is made early.

Possible causes:

• Incorrect paper settings

• Defective exit sensor

1. Check for anything in the paper path that might

cause the paper to jam.

2. If clearing the jam does not solve the problem,

go to “121.xx—Fuser error service check” on

page 2-70.

202.03 Exit sensor is never made.

Possible causes:

• Improper paper loading

• Paper wrapped in fuser

• Damaged paper exit sensor or

paper exit sensor flag

• Damaged fuser autoconnect

• Faulty fuser DC cable connection

• Faulty fuser

• Faulty system board

1. Check for anything in the paper path that might

cause the paper to jam.

2. The fuser exit sensor may not be functioning

properly. Go to “121.xx—Fuser error service

check” on page 2-70.

202.04 Exit sensor broke early.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Faulty fuser

• Faulty system board

The fuser exit sensor may not be functioning

properly. Go to “121.xx—Fuser error service

check” on page 2-70.

202.05,

202.07

Exit sensor never broke.

Possible causes:

• Damaged paper exit sensor or

paper exit sensor flag

• Faulty fuser

• Faulty system board

• Faulty output bin flag

1. Check exit sensor flag on fuser for proper

operation. Be sure the paper is not hanging on

the flag.

2. The fuser exit sensor may not be functioning

properly. Go to “121.xx—Fuser error service

check” on page 2-70.

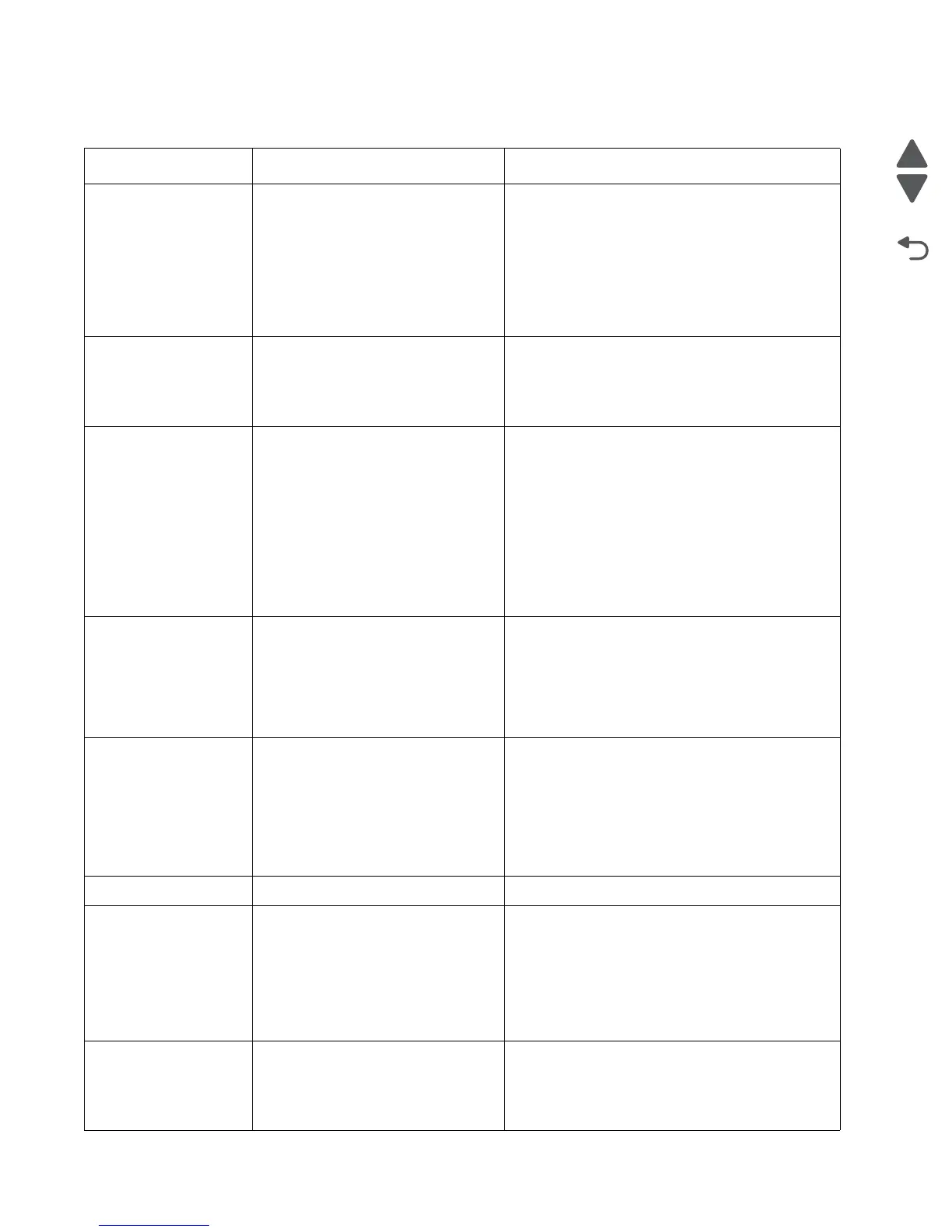

202.08 Exit sensor is never made. See “202.03” on page 2-10.

202.31 Bin-full sensor active when printing

started.

Possible causes:

• Paper jam leaving paper over the

sensor

• Damaged bin-full sensor

• Faulty system board.

1. Clear away anything in the paper path that might

cause the paper to jam.

2. Be sure the paper settings match the media.

3. Flex the media, and stack it flat in the tray.

4. Properly set the paper guides in the paper tray.

5. If the problem persists, go to “Pick arm stuck

down service check” on page 2-164.

202.32 Binfull sensor is made early.

Possible causes:

• Incorrect paper settings

• Defective bin-full sensor

1. Check for anything in the paper path that might

cause the paper to jam.

2. If clearing the jam does not solve the problem,

go to “202.32—Paper Jam error service

check” on page 2-107.

Loading...

Loading...