Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 407

Chapter 12 Motion Control Applications

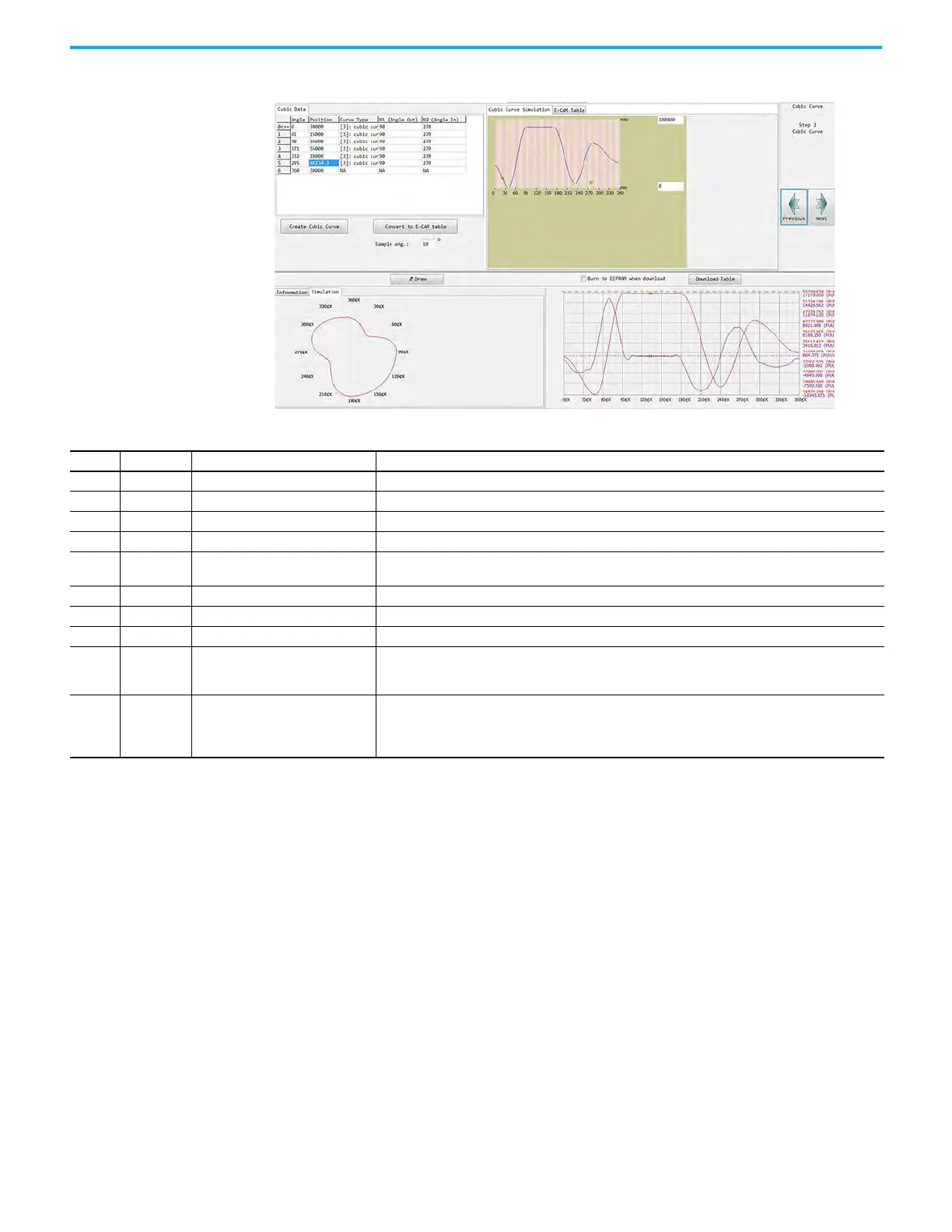

Figure 216 - E-CAM Cubic Curve Table

Table 124 - E-CAM Wizard Parameter Definitions

ID Parameter Name Description

369 P5.081 E-CAMStart Address This is the starting address of the Data Array that is used as the first point in the E-CAM profile.

370 P5.082 E-CAM Area Number This is the length of the Cam profile - this value uses the data array (max 720).

373 P5.085 E-CAM Engaged Area Number Data Array index value used as the first cam point to be executed.

374 P5.086 E-CAM Master Axis position Displays the feedback Position of the Master feedback source.

375 P5.087 E-CAM Lead Pulse Before Engaged

Master Offset Position - from when the enable permissives are met and the E-CAM is ready to execute, this

number of pulses occurs before the slave begins following.

378 P5.090 E-CAM DO.CAM_Area Valid Start Angle Specify the rising edge of the DO that can be used to show the E-CAM is engaged (Master pulses).

379 P5.091 E-CAM DO.CAM_Area Valid End Angle Specify the falling edge of the DO that can be used to show E-CAM is Engaged (Master units).

311 P5.019 E-CAM Curve Scale Used to change the amplitude of the cycle profile in terms of speed (positioning follows the cycle profile).

371 P5.083 E-CAM SlaveCycleNumber M

This profile is executed according to this value. If 2 is entered, the entire cycle profile executes 2 times

and the speed is also 2x as fast. If 3 is entered, the cycle profile is executed 3 times and the speed is 3

times as fast

372 P5.084 E-CAM MasterPulseNumber P

The E-CAM editor uses 0…360 for master units and is not changeable. If your machine cycle is not

representative within the 0…360 units; for example, using time and 4000 ms for one machine cycle, enter

the value used to represent one machine cycle. This value is the normalizing parameter used for the E-

CAM.

Loading...

Loading...