456 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Chapter 16 Troubleshoot the Kinetix 5100 Drive System

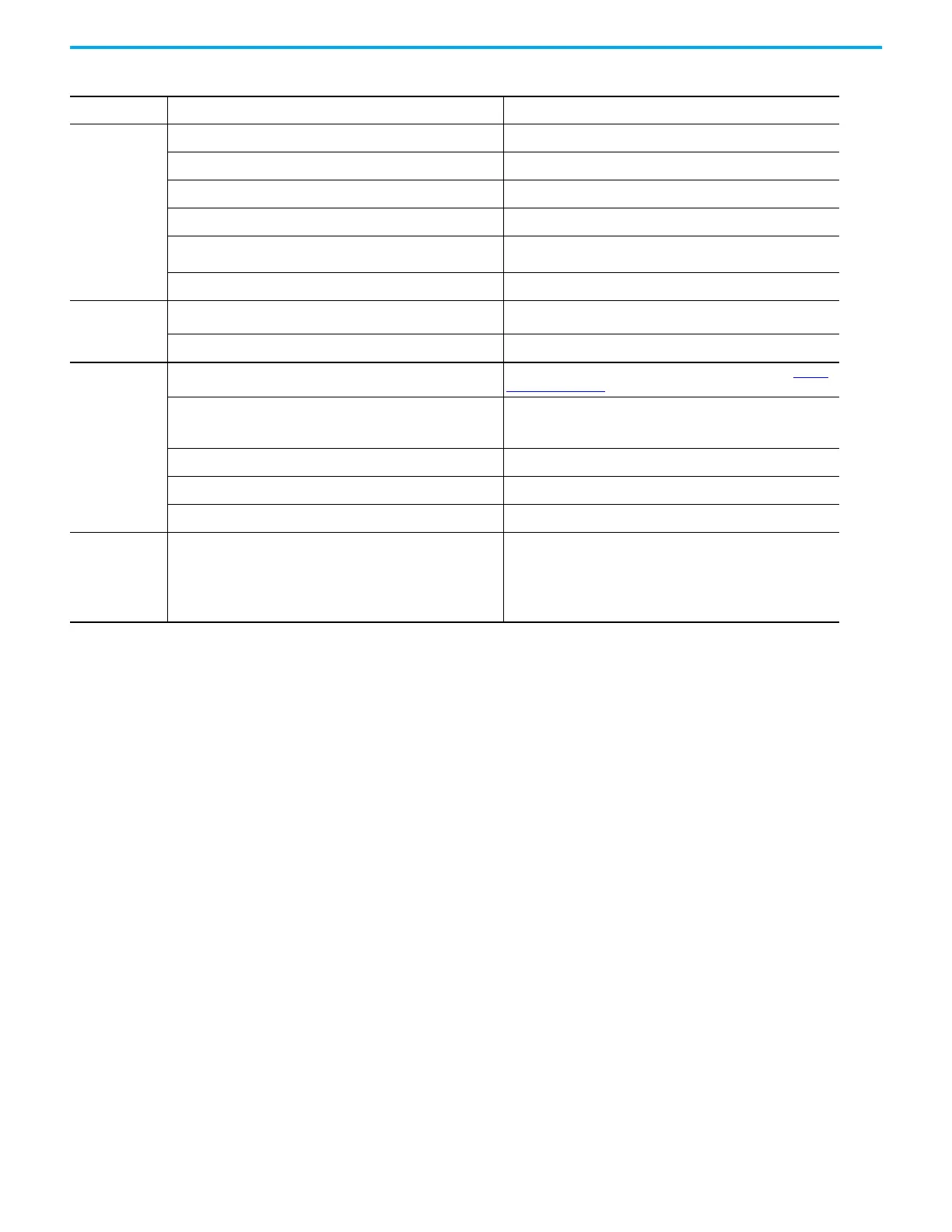

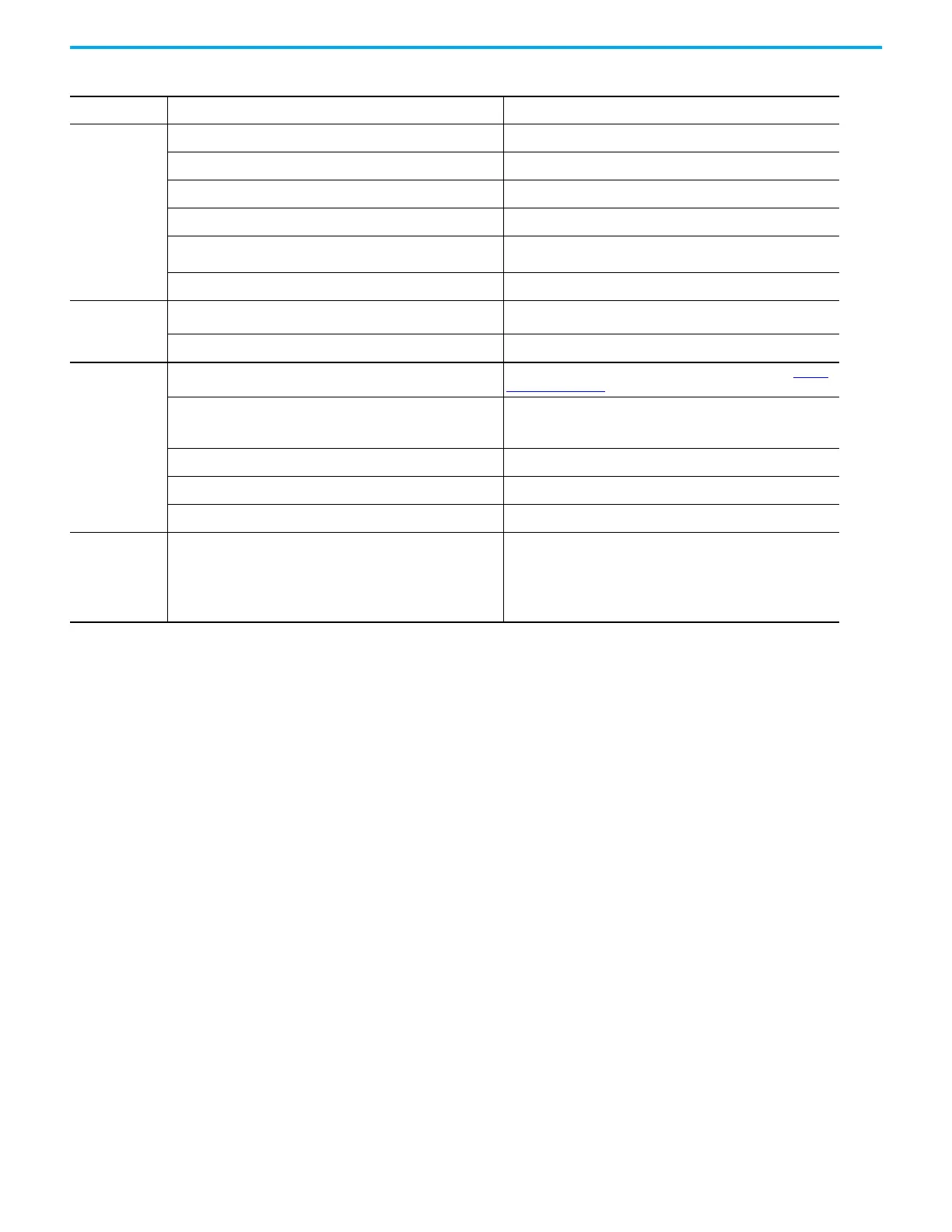

No rotation

The motor connections are loose or

open. Check motor wiring and connections.

Foreign matter is lodged in the motor. Foreign matter is lodged in the motor. Remove foreign matter.

The motor load is excessive. The motor load is excessive. Verify the servo system sizing.

The bearings are worn. The bearings are worn. Return the motor for repair.

The motor brake is engaged (if supplied).

• Check brake wiring and function.

• Return the motor for repair.

The motor is not connect to the load. Check the coupling.

Motor overheating

The duty cycle is excessive.

Change the command profile to reduce acceleration/deceleration, or

increase time.

The rotor is partially demagnetized causing excessive motor current. Return the motor for repair.

Abnormal noise

Motor tuning limits are set too high.

Run Tune by using KNX5100C software or the LED panel. See Tuning

Process on page 200.

Loose parts are present in the motor.

• Remove the loose parts.

• Return motor for repair.

• Replace motor.

Through bolts or coupling is loose. Tighten bolts.

The bearings are worn. Return motor for repair.

Mechanical resonance. Notch filter can be required.

Erratic operation–

Motor locks into

position, runs

without control, or

with reduced

torque.

Motor power phases U and V, U and W, or V and W reversed. Check and correct motor power wiring.

Table 144 - Troubleshooting (Continued)

Condition Potential Cause Possible Resolution

Loading...

Loading...