512 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Appendix C Use Add-On Instructions

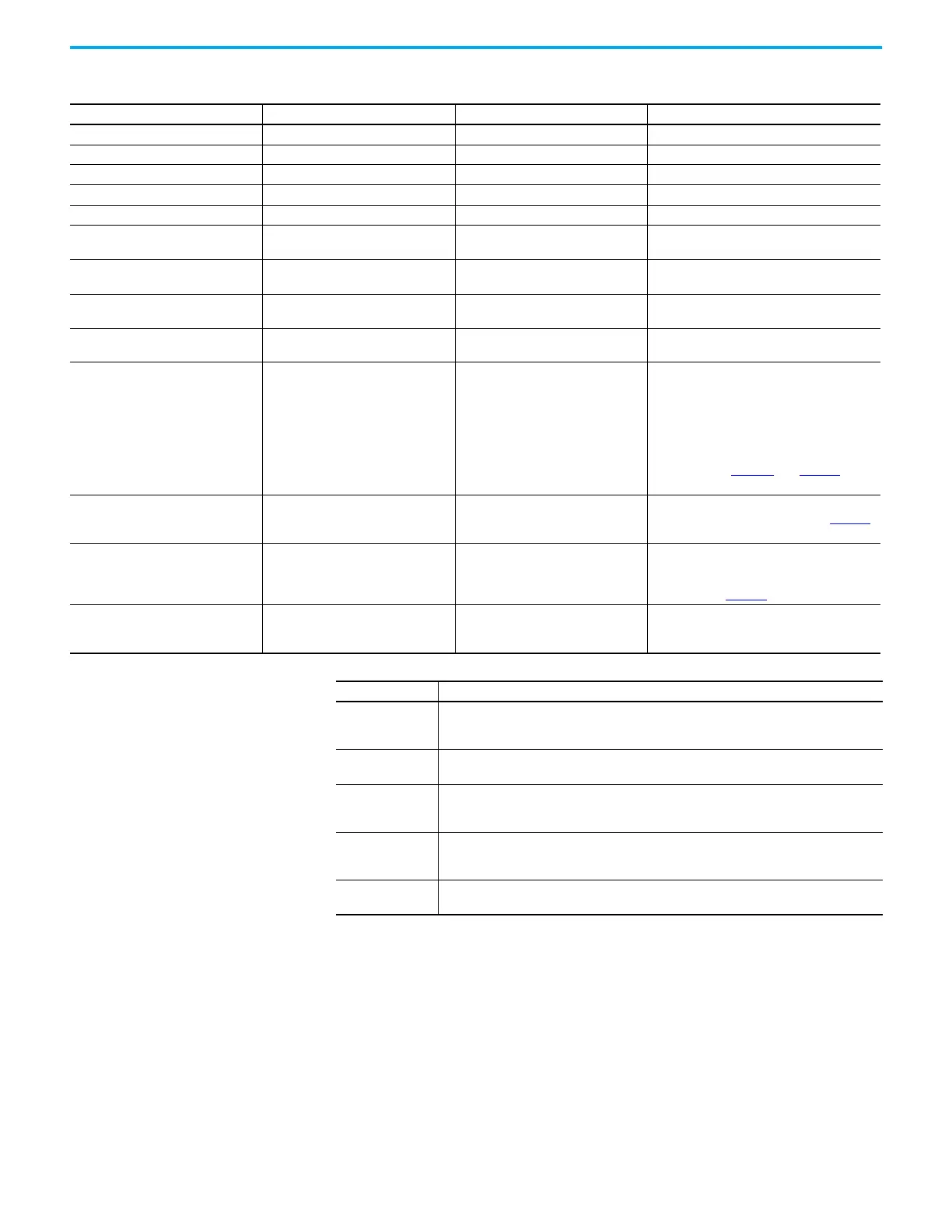

Operands

Operand Type Format Description

Instance raC_xxx_K5100_MAM Tag Unique instance of the MAM Add-On Instruction

Ref_Ctrl_Cfg raC_UDT_Itf_PowerMotionSA_Cfg Tag Interface for Ctrl_Cfg of the Device Object

Ref_Ctrl_Set raC_UDT_Itf_PowerMotionSA_Set Tag Interface for Ctrl_Set of the Device Object

Ref_Ctrl_Cmd raC_UDT_Itf_PowerMotionSA_Cmd Tag Interface for Ctrl_Cmd of the Device Object

Ref_Ctrl_Sts raC_UDT_Itf_PowerMotionSA_Sts Tag Interface for Ctrl_Sts of the Device Object

Set_PositionReference REAL Immediate or Tag

Set the Target Distance/Position Reference

(PUU) Range: -2,147,483,648…+2,147,483,647

Set_SpeedReference REAL Immediate or Tag

Units are 0.1 rpm for rotary motors

Range: -80,000…+80,000

Set_AccelReference REAL Immediate or Tag

Units are 0.1 rpm/s for rotary motors

Range: 458…30,000,000

Set_DecelReference REAL Immediate or Tag

Units are 0.1 rpm/s for rotary motors

Range: 458 …30,000,000

Set_MoveType INT Tag

Specify the type of move:

0 = Absolute

1 = Incremental

2 = Rotary Shortest Path

3 = Rotary Positive

4 = Rotary Negative

7 = Relative

8 = Capture (see page 337

, and page 514 for

details)

Set_PositionCommandOverride BOOL Tag

0 = Do not interrupt previous movement

1 = Interrupt previous movement (see page 514

for details)

Set_PositionCommandOverlap BOOL Tag

0 = Current movement is not overlapped with

next

1 = Current movement is overlapped with next

movement (see page 514

for details)

Set_CapturedPositionSelect BOOL Tag

0 = First High Speed Capture (triggered by DI9)

1 = Second High Speed Capture (triggered by

DI10)

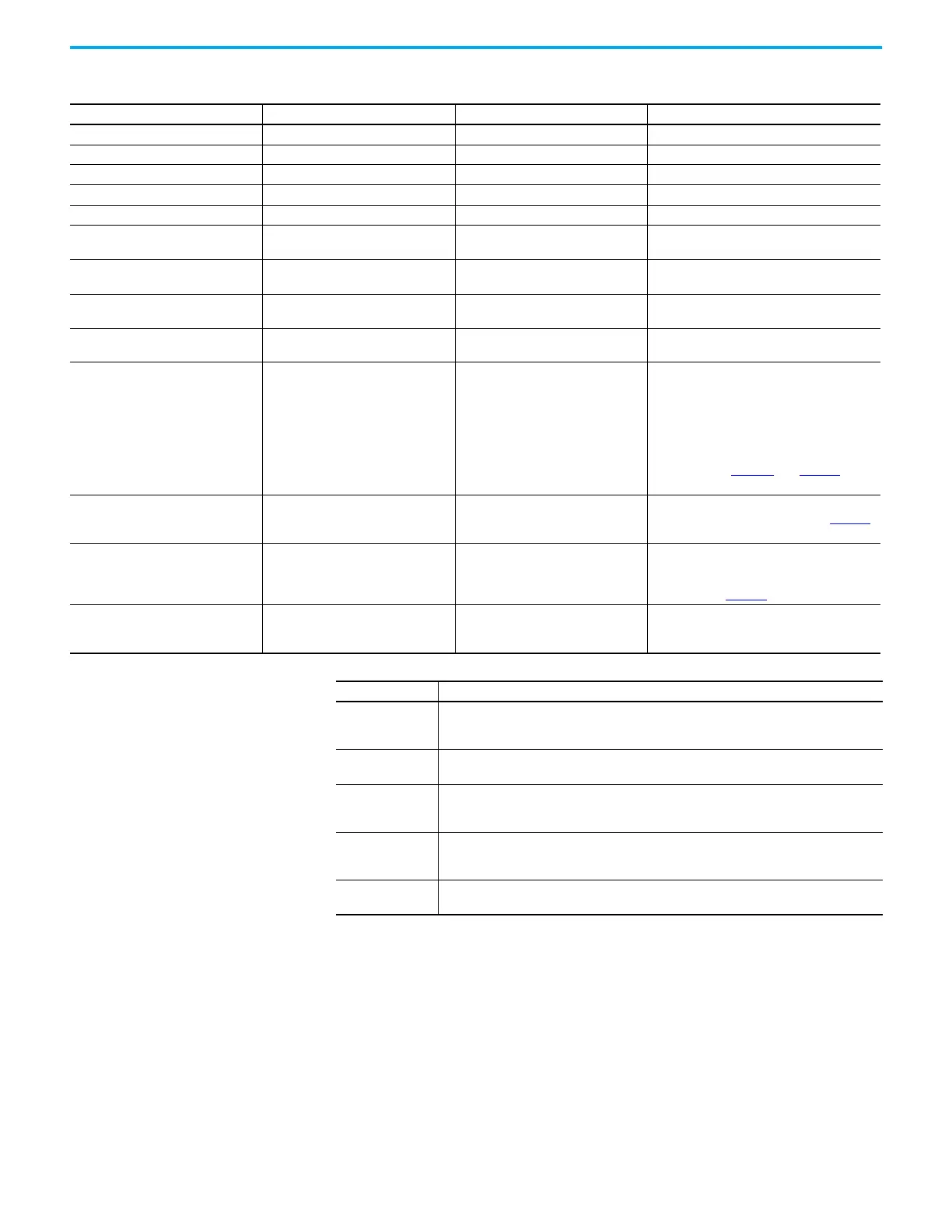

Mnemonic Description

Sts_EN (Enable)

This bit is set when the rung makes a false-to-true transition and the message transaction

to Index is initiated and in process. It remains high until the rung-in condition is false and no

faults are active.

Sts_DN (Done)

This bit is set when the rung makes a false-to-true transition and the message transaction

to Index the drive (Sts_EN) is complete.

Sts_ER (Error)

This bit is set when the rung makes a false-to-true transition and there is an error that has

occurred with the instruction. (This instruction error can be as a result of a fault on the drive

itself). See Sts_ERR for details on the cause of the error.

Sts_IP (In Progress)

This bit is set when the rung makes a false-to-true transition, the Index message transaction

is successful, and the motor begins to move. This bit remains set as the motor is executing

the index.

Sts_PC (Process

Completed)

This bit is set when the rung makes a false-to-true transition, the Index message transaction

is successful, and the motor reaches the Target position.

Loading...

Loading...