Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 241

Chapter 10 Modes of Operation

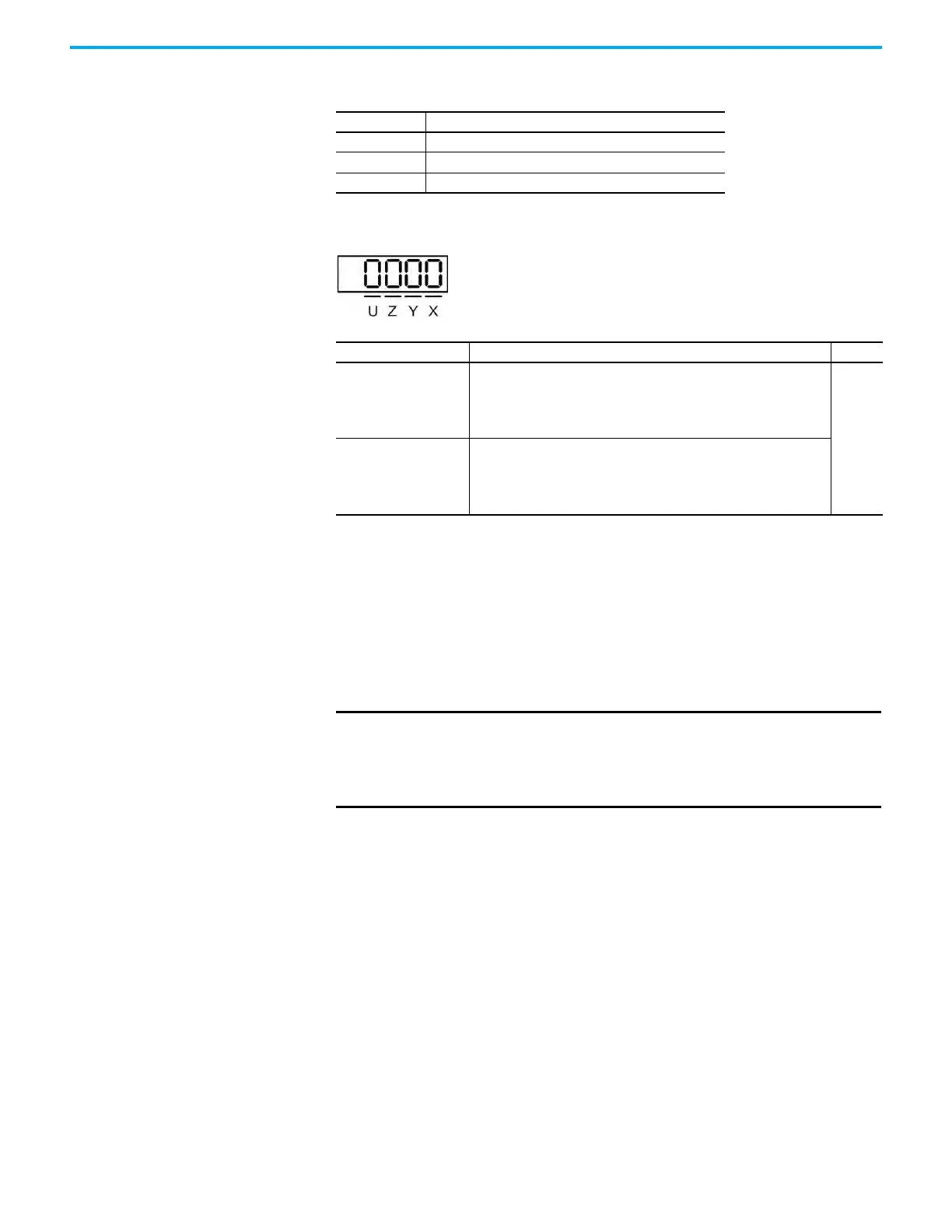

The decryption of ID167 (P1.064) is shown in the segment display image that

corresponds to the table:

Settings for ID168 (P1.065):

The analog position command smoothing constant is only valid for analog

position commands. This value is the amount of smoothing that is used

essentially for speed control when the motor is moving towards the analog

setpoint. The smaller value (0) is a very aggressive speed that is used to move to

the analog setpoint. The largest value (1000) is a very slow speed that is used to

move to the analog setpoint.

Table 87 - Relevant Parameters

Parameter Name

ID167 (P1.064) AnalogToPositionStartupConfiguration

ID168 (P1.065) AnalogToPositionSmoothTime

ID169 (P1.066) AnalogToPositionMaxRotationNum

Bit X: Bit Y: Bit U/Z:

0 = The analog position

function is not used

(disabled).

0 = When the drive transitions to ON, the current motor position is

considered 0V; the motor now moves to the corresponding motor position

based on the voltage level at V_REF/GND. The amount of movement is

defined by the volts/rev setting shown below and the speed of the

movement uses the Smoothing Constant described below.

Reserved

1 = The analog position

function is used (enabled).

1 = When the drive transitions to ON, the current motor position is

considered 0V; the motor now moves to the corresponding motor position

based on the voltage level at V_REF/GND. The amount of movement is

defined by the volts/rev setting shown below and the speed of the

movement uses the Smoothing Constant described below.

IMPORTANT

Choose the smoothing constant carefully because aggressive speed

settings can potentially damage your equipment. By using a smoothing

constant of 0 or 1, you are creating, essentially, a step input to

maximum speed as defined by the Volts/(Max. Rotation Number). A

typical value for the smoothing constant is 200…400.

Loading...

Loading...