Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 381

Chapter 12 Motion Control Applications

Example 1:

When ID179 (P1.097) = 5; ID153 (P1.046) = 2500

Example 2:

When ID179 (P1.097) = 7; ID153 (P1.046) = 2500

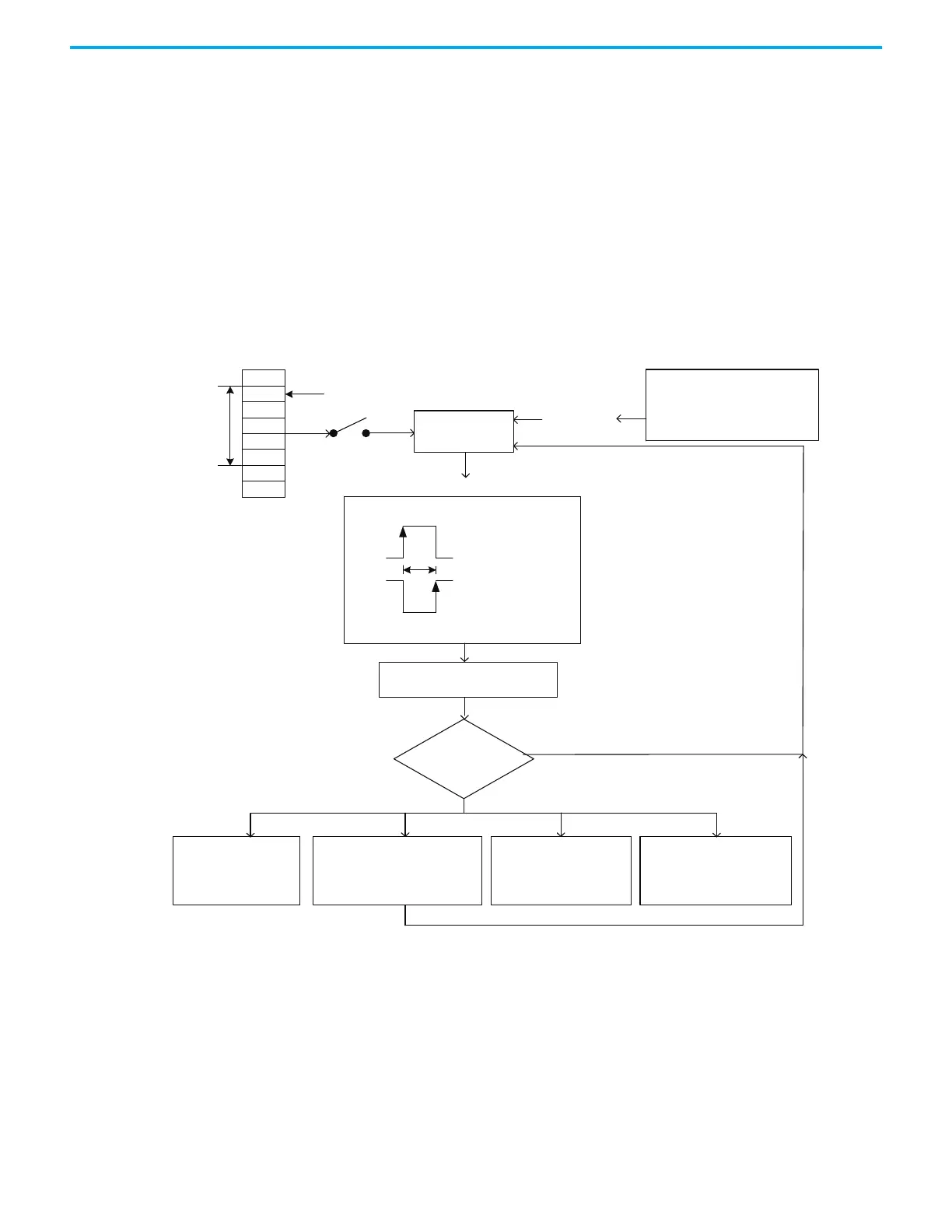

Figure 188 - High Speed Position Compare Flowchart

OA/OB output

2500

5

----------

500 pulses==

OA/OB output

2500

7

----------

357.142857 pulses==

No

Data array

≥

1234

2345

5678

6789

7890

DO4

DO4

Yes

CAP

amount

ID350 (P5.058)

Start address

ID348 (P5.056)

CMP switch

ID351 (P5.059.X) Bit0

CMP axis

position 7890

CMP axis

position

ID349 (P5.057)

CMP axis source

AUX ENC ID351 (P5.059.Y) = 1

Pulse Cmd ID351 (P5.059.Y) = 2

Main ENC ID351 (P5.059.Y) = 3

CMP trigger logic

Normally open

ID351 (P5.059.Z) = 0

Pulse output duration

ID351 (P5.059.CBA)

Normally closed

ID351 (P5.059.Z) = 1

CMP amount

ID350 (P5.058) = ID350 (P5.058) - 1

CMP completed?

ID350 (P5.058) = 0

Call PR#45

ID351 (P5.059.U) Bit 0 = 1

Cyclic CMP

ID351 (P5.059.X) Bit 1 = 1

ID350 (P5.058) = Previous setting

value

Enable CAP after

completed

ID351 (P5.059.X) Bit 2 = 1

CMP axis position resets to

0

ID351 (P5.059.X) Bit 3 = 1

Loading...

Loading...