46 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Chapter 2 Plan and Install the Kinetix 5100 Drive System

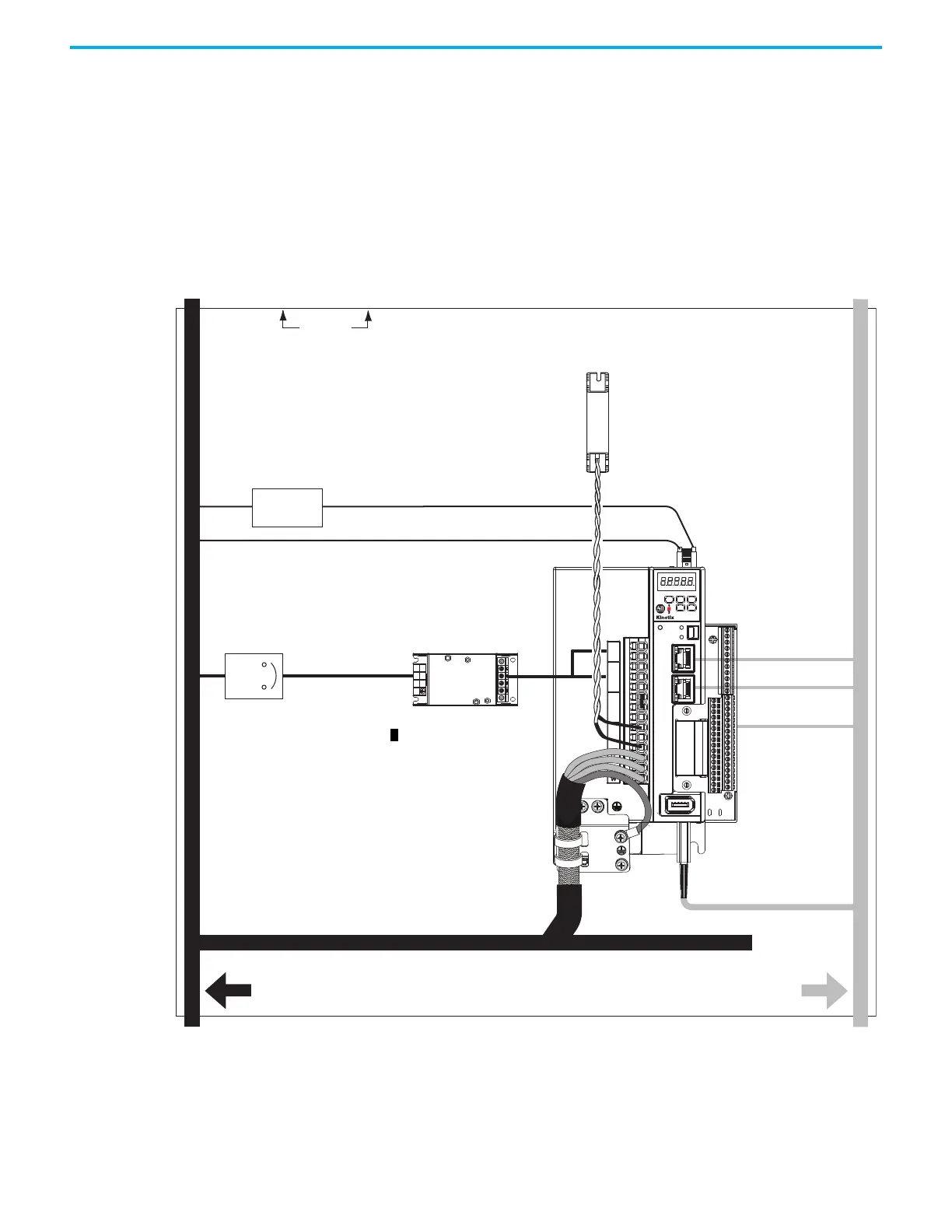

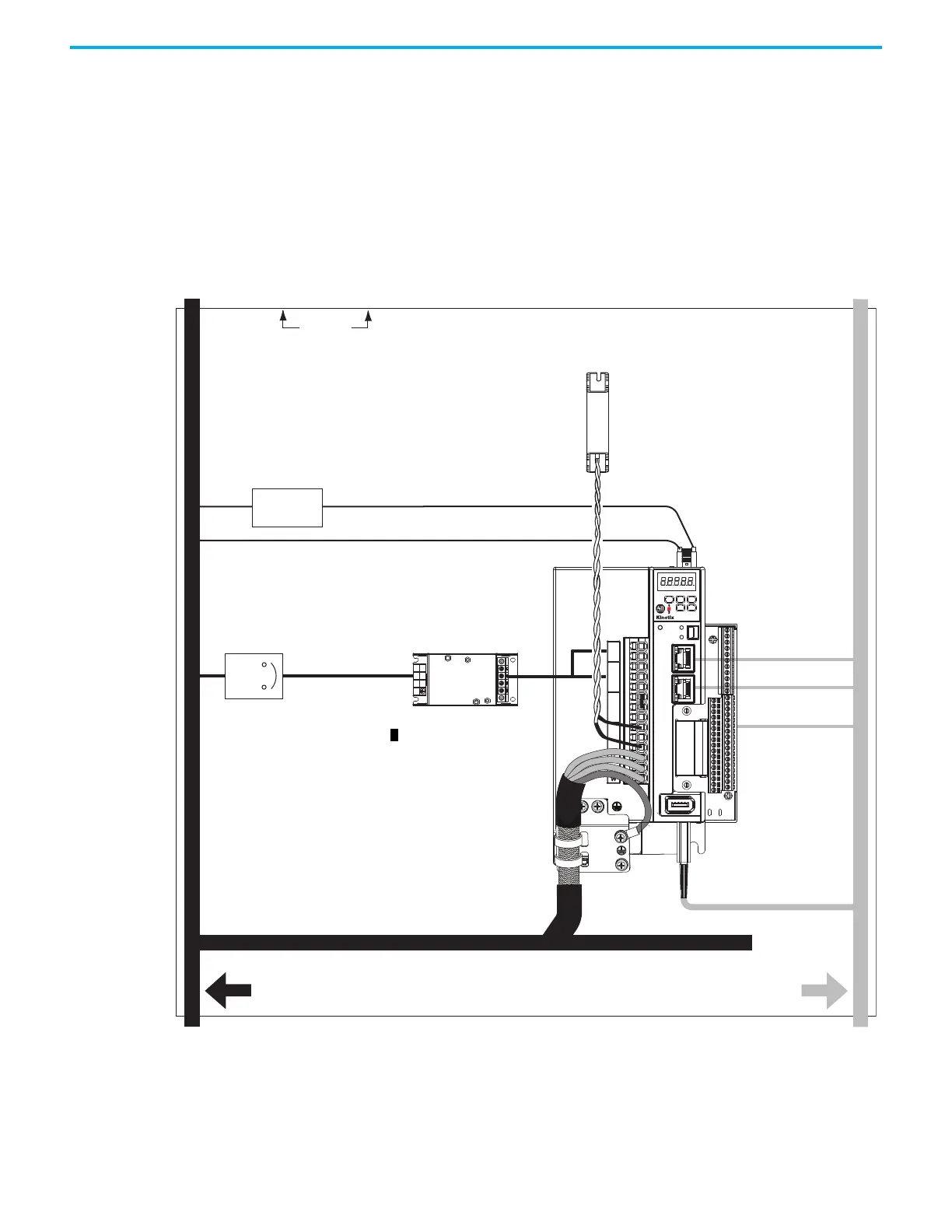

Observe these guidelines when mounting your Bulletin 2198 and 2097 external

passive shunt inside the drive system enclosure:

• Mount the shunt resistors anywhere in the dirty zone, but as close to the

Kinetix 5100 power supply as possible.

• Route the shunt power wires with other very dirty wires.

• Keep unshielded wiring as short as possible, not to exceed 457 mm

(18 in.). Keep shunt wiring as flat to the cabinet as possible.

• Separate shunt power cables from other sensitive low-voltage signal

cables.

Figure 15 - External Shunt Resistor Mounted Inside the Drive System Enclosure

D

C

D

D

VD

C

C

D

5100

2

1

NET

MOD

CHARGE

I/0

AUX

U

V

W

DC+

ISH

ESH

P1

P2

DC–

L1

L2

L3

L1C

L2C

L1 L2

L3

VD

Dirty Wireway

No sensitive

equipment within

150 mm (6.0 in.)

Clean Wireway

Enclosure

Shunt Power Wiring Methods:

Twisted-pair in conduit (1st choice).

Twisted-pair, two twists per foot (min) (2nd choice).

76 mm (3.0 in.)

clearance (min) below, left,

and right of the shunt resistor.

150 mm (6.0 in.)

clearance (min) above the

shunt resistor.

Kinetix 5100

Servo Drive

Motor Power Cable

Digital Inputs and

Ethernet (shielded)

Cables

AC Line Filter

(required for CE and UK)

Circuit

Protection

24V DC

Power Supply

Very Dirty Filter/AC Input

Connections Segregated

(not in wireway)

Route motor cables

in shielded cable.

Hardwired Safety Cable

Motor Feedback Cable

Route registration and communication

signals in shielded cables.

Loading...

Loading...