Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 99

Chapter 4 Connect the Kinetix 5100 Drive System

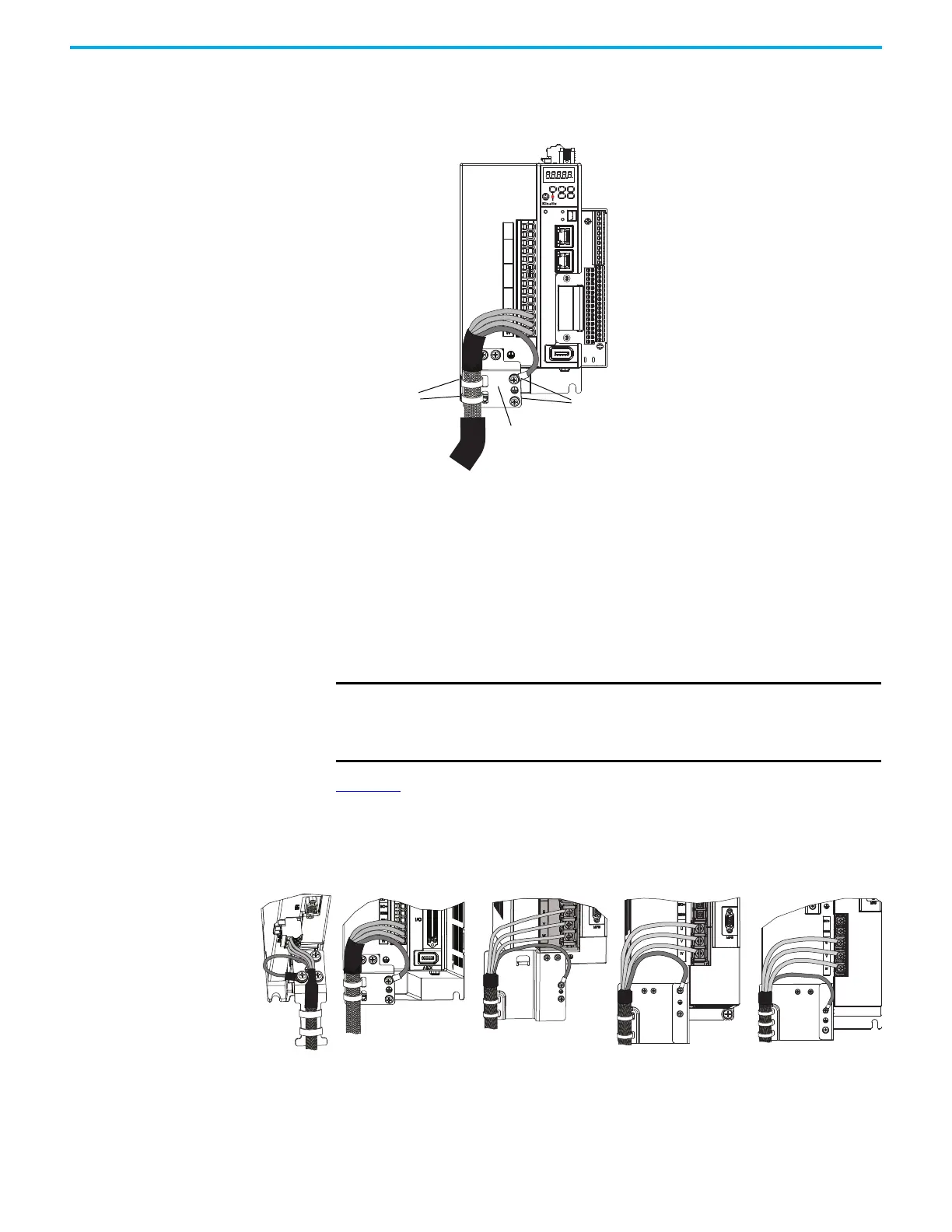

Follow these steps to apply the cable shield clamp.

1. Route the conductors with service loops to provide stress relief to the

motor power and brake conductors.

2. Apply tie wraps through the ground plate slots and around the exposed

cable shield.

Make sure the cable clamp tightens around the cable shield and provides

a good bond between the cable shield and the drive chassis.

3. Attach the motor-power ground wire to one of the PE ground screws.

Tighten the PE ground screw to a maximum torque value of 2.0 N•m

(17.7 lb•in).

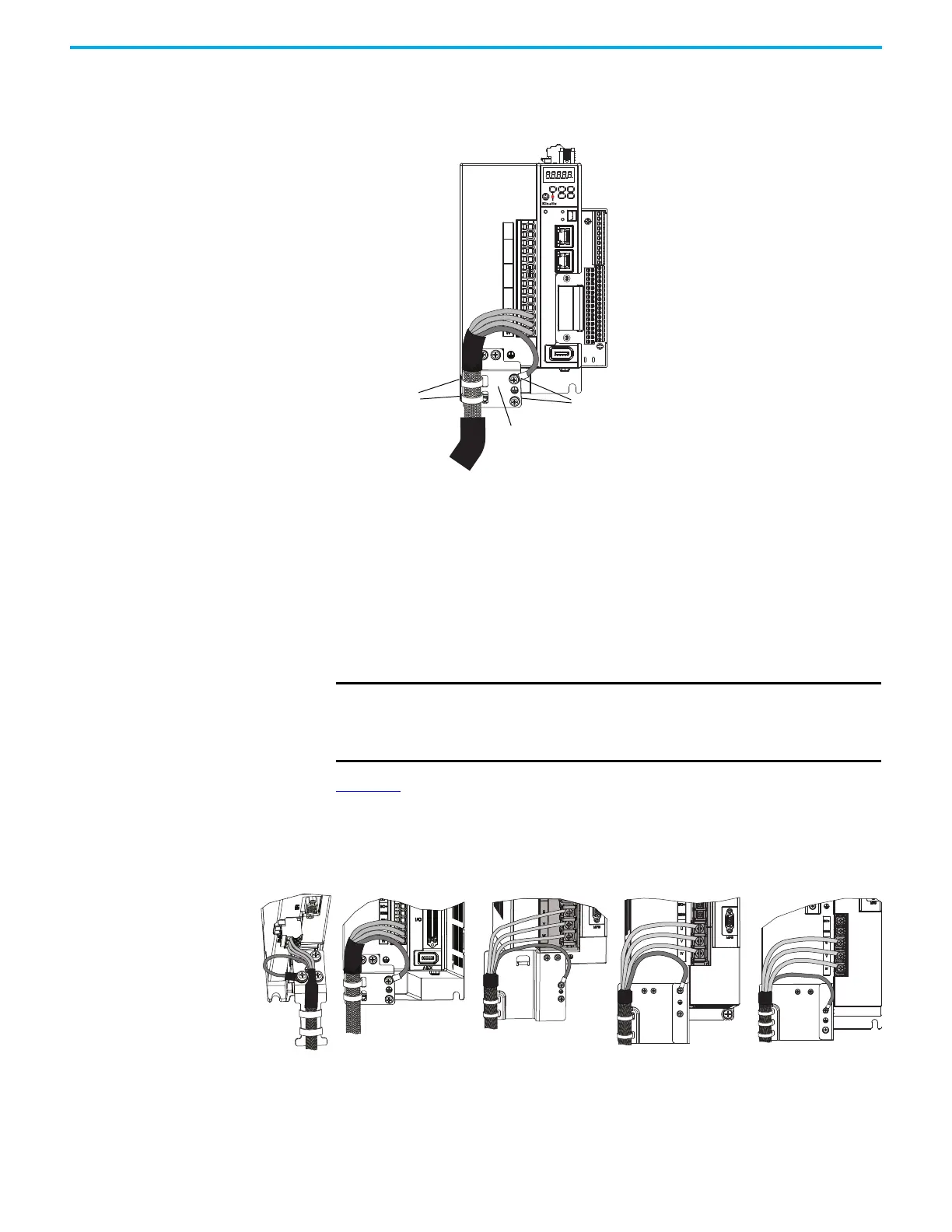

Figure 64

displays examples of how the motor cable conductors and shield can

be routed and attached for each of the servo drives.

Figure 64 - Kinetix 5100 Drive Ground Plate Examples

D

5100

2

1

NET

MOD

CHARGE

I/0

AUX

U

V

W

DC+

ISH

ESH

P1

P2

DC–

L1

L2

L3

L1C

L2C

Tie Wraps

PE Ground Screws

Grounding Plate

IMPORTANT

If the power/brake cable shield has a loose fit between the ground

plate and tie wraps, the cable shield ground is ineffective. When the

tie wraps are pulled tight, the result must be a high-frequency bond

between the cable shield and the drive chassis.

2198-E1004-ERS

2198-E1007-ERS

2198-E1015-ERS

2198-E1020-ERS

2198-E2030-ERS

2198-E2055-ERS

2198-E4055-ERS

2198-E2075-ERS

2198-E4075-ERS

2198-E2150-ERS

2198-E4150-ERS

2198-E4004-ERS

2198-E4007-ERS

2198-E4015-ERS

2198-E4020-ERS

2198-E4030-ERS

Loading...

Loading...