180 Rockwell Automation Publication 2198-UM004D-EN-P - December 2022

Chapter 7 Configure the Drive with KNX5100C Software

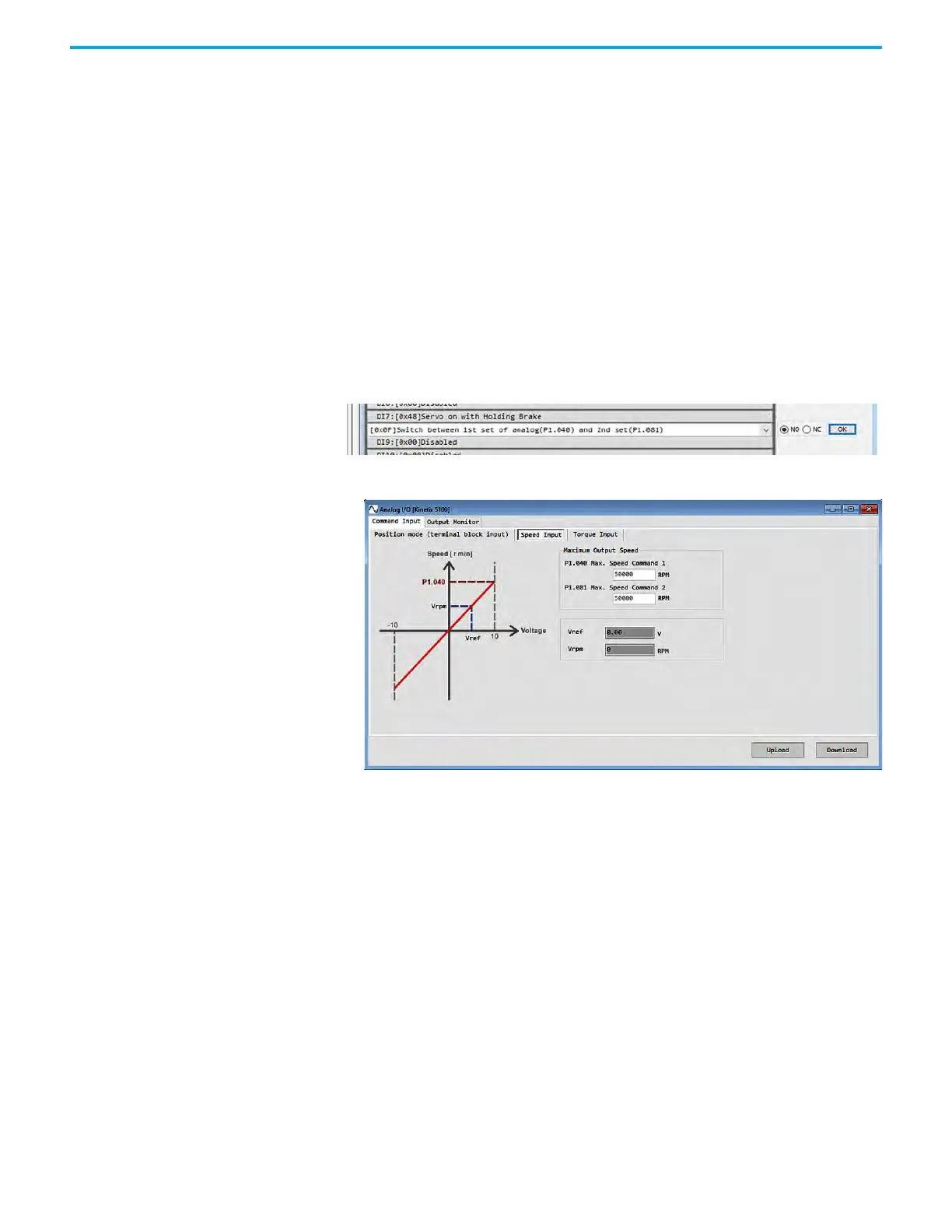

Speed Input Tab

This mode is useful when you want to relate an analog voltage command to

motor speed. By using the analog input, you can relate an analog voltage to a

motor speed in RPM. Use this feature to define positive (up to +10V) or

negative (down to -10V) speed. The conversion of volts/motor RPM used here

is:

10V yields a maximum of P1.040 (Maximum Output Speed) RPM.

The volts/RPM is scaled using this formula. For example, if a ControlLogix®

1756-M02AE module was configured for Velocity mode, its analog output could

be used with this speed input for the Kinetix 5100 drive to provide full closed-

loop control.

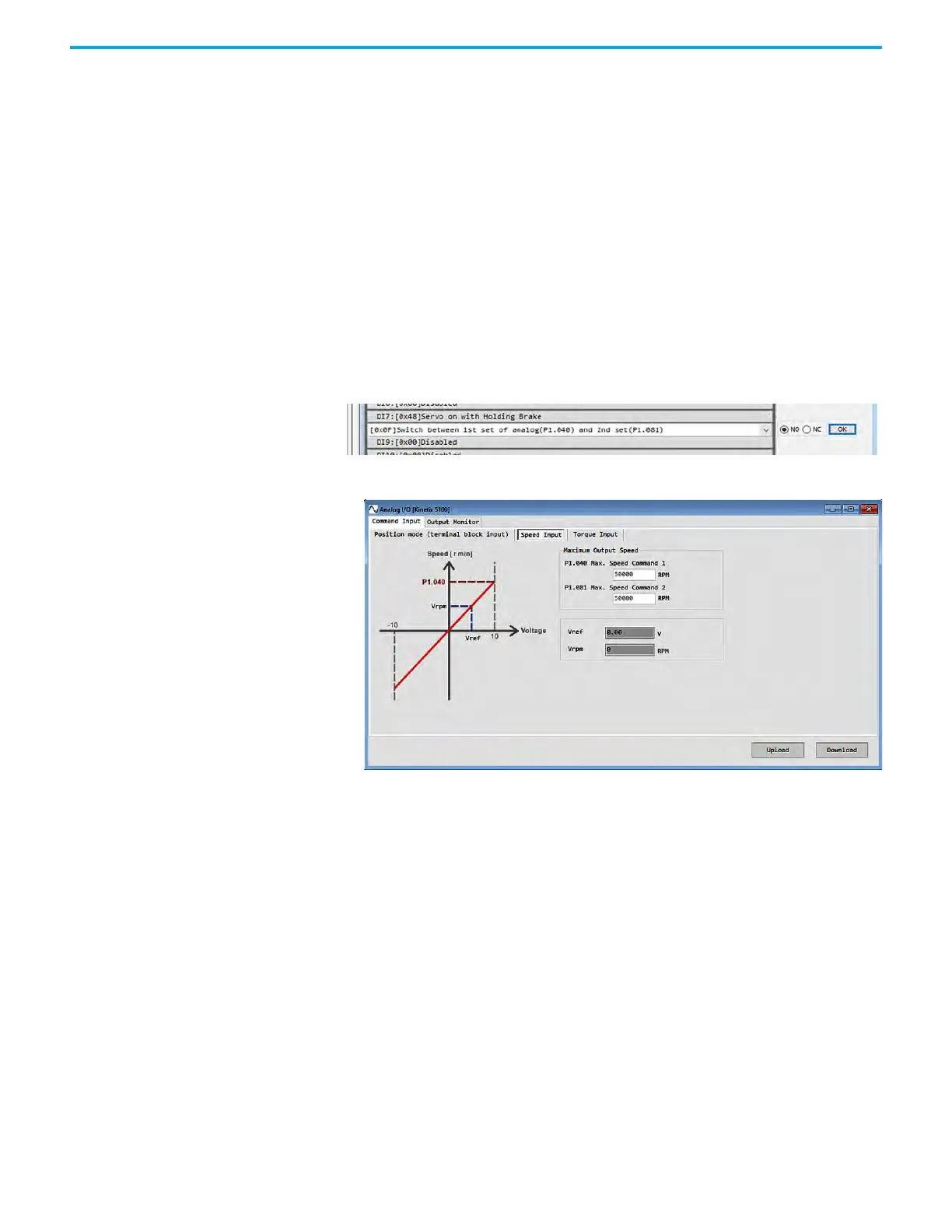

On this tab, you can set the maximum output speed by using parameters

ID147 (P1.040) and ID679 (P1.081). Select the Max Speed value by using a

Digital Input.

Click Download to write any changed parameters to the servo drive.

Torque Input Tab

This mode is useful when you want to relate an analog voltage command to

motor torque. By using the analog input, you can relate an analog voltage to a

motor torque. Use this feature to define positive (up to +10V) or negative

(down to -10V) torque limits. The conversion of volts/motor torque used here

is: 10V yields a maximum of P1.041 (Maximum Output Torque). The volts/

motor torque % is scaled by using this formula. For example, if a ControlLogix

1756-M02AE module was configured for Torque mode, its analog output could

be used with this torque input for the Kinetix 5100 drive to provide full closed-

loop control.

Loading...

Loading...