Rockwell Automation Publication 2198-UM004D-EN-P - December 2022 405

Chapter 12 Motion Control Applications

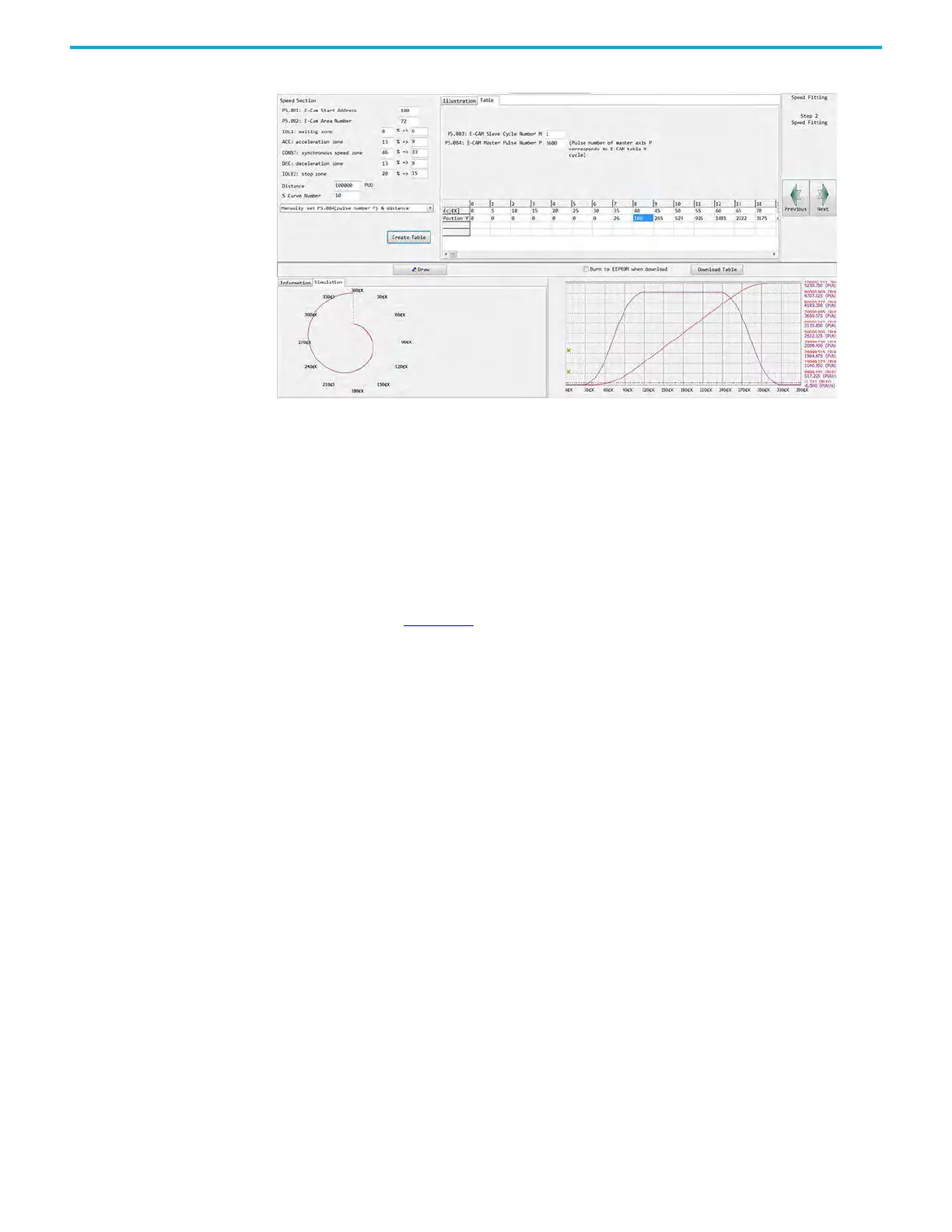

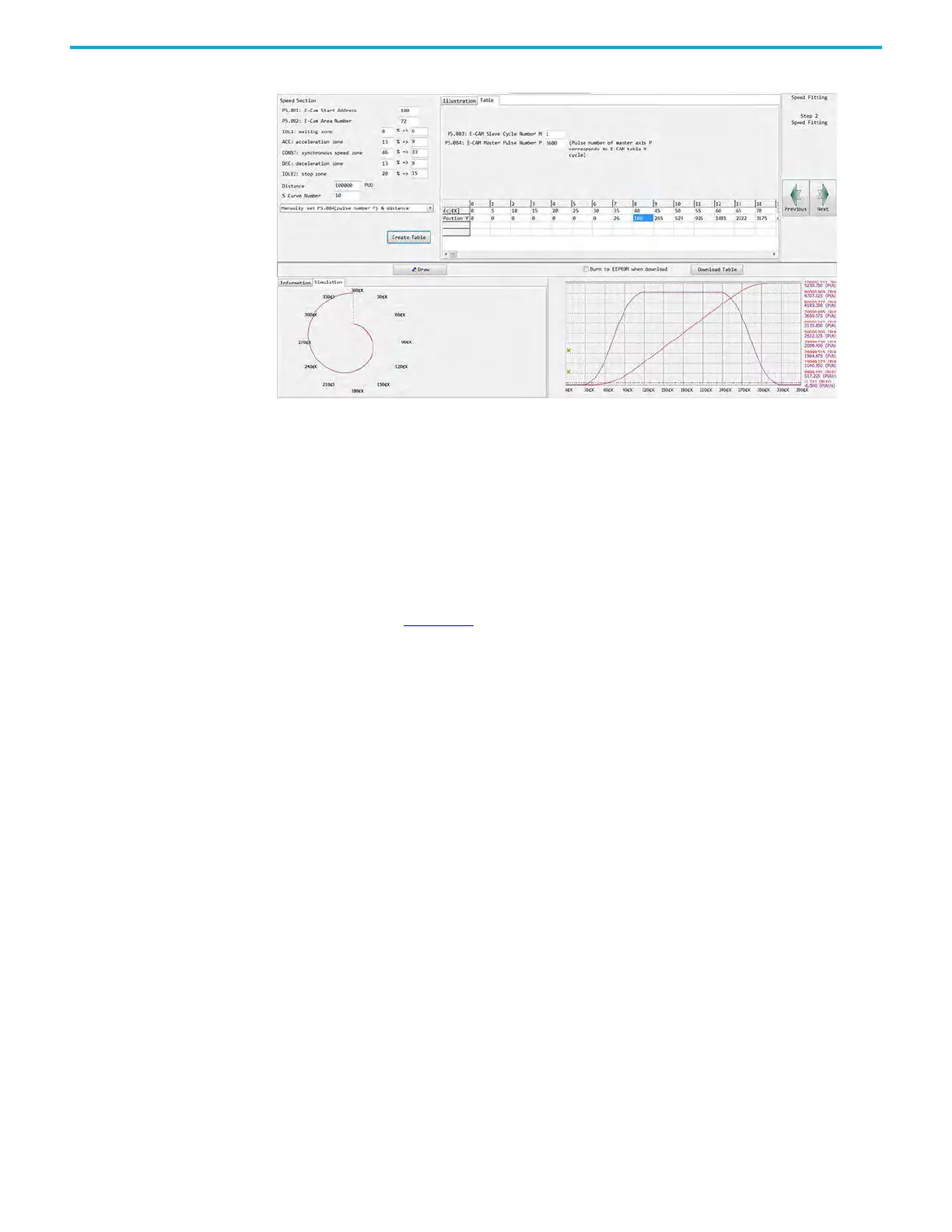

Figure 214 - E-CAM Speed Fitting Table

Cubic Curve

When the master-slave axis only has position correspondence, such as point-

to-point correspondence, then the cubic curve can be used to create an

electronic cam curve. When using the cubic curve to create a table, you only

need to fill in the phase angle with the corresponding slave axis position. The

software automatically draws and optimizes the curve. Some applications

require a point-to-point motion trajectory, such as a straight line or a curve.

The E-CAM curve creation is simplified by the cubic curve creation method. As

shown in Figure 215

, the starting angle N1 (the angle from the starting point)

and the ending angle N2 (the angle of entering the target point) can be set

according to the application requirements. There are three different types of

curve:

• Straight line — There is a straight line between the two data points of the

cam. The starting angle and the ending angle are not adjustable.

• Constant acceleration — A unidirectional increasing or decreasing curve

with an equal acceleration and deceleration. Only the starting angle can

be adjusted.

Loading...

Loading...