9 Arc Welding Application

9.2 General Descriptions of Instructions and Functions

9-4

149235-1CD

RE-CSO-A031

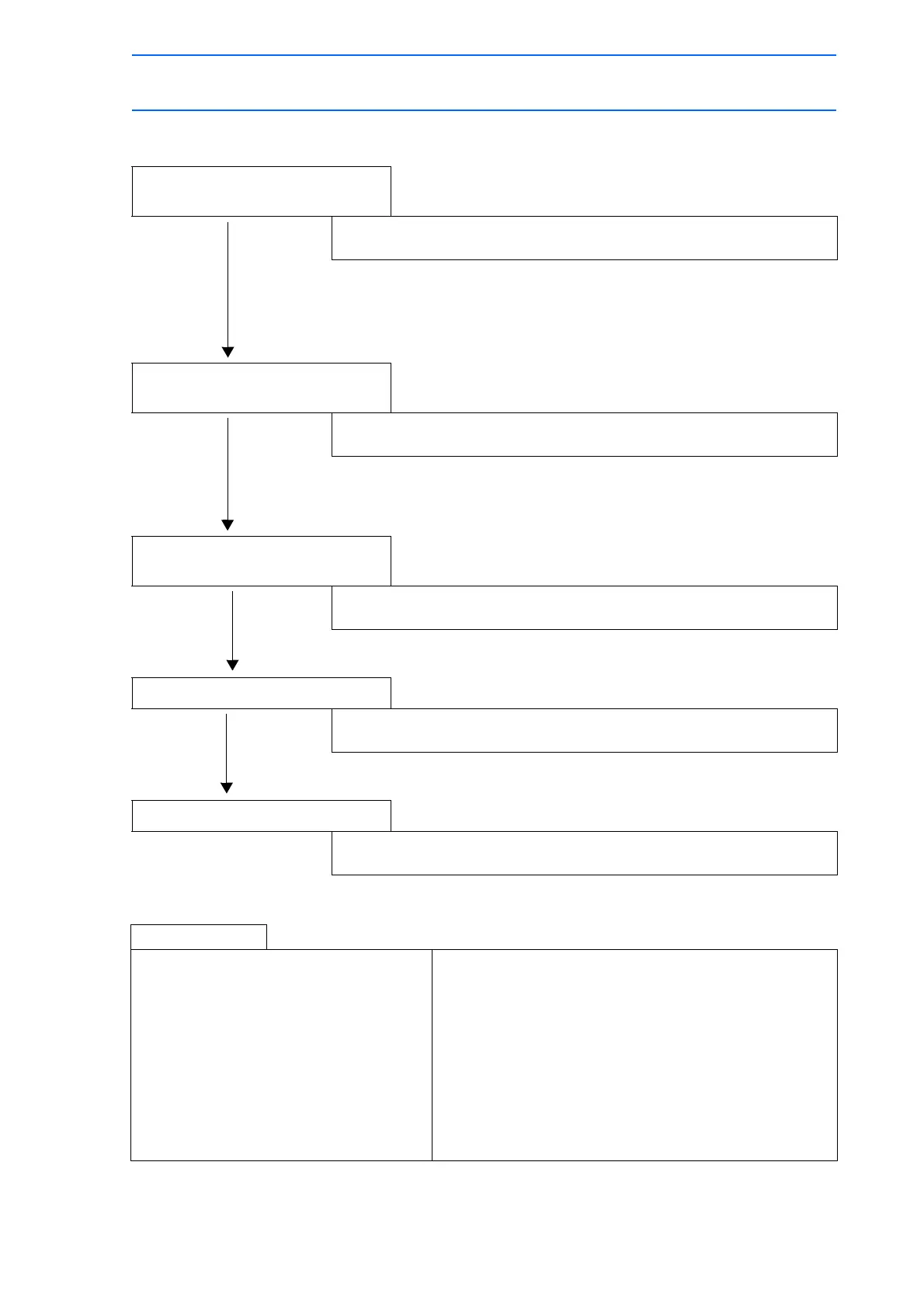

Operating procedure is as follows:

C re at i ng a J o b

(Teaching a Welding Line)

Perform the manipulator welding teaching operation. (Refer to the

reference job.)

Setting Welding Conditions

(Registering Work Instruction)

Set the welding conditions (current value, voltage value, welding speed)

for the object workpiece.

Check Operation

(Operation in the Check Mode)

Confirm the manipulator operation in the check mode (welding is not

performed).

Fine Control of Welding Condition

Execute welding, and perform the fine control of the welding condition

from the bead externals.

Production (Automatic Drive)

The teaching operation is completed. Actual production using the

manipulator is performed.

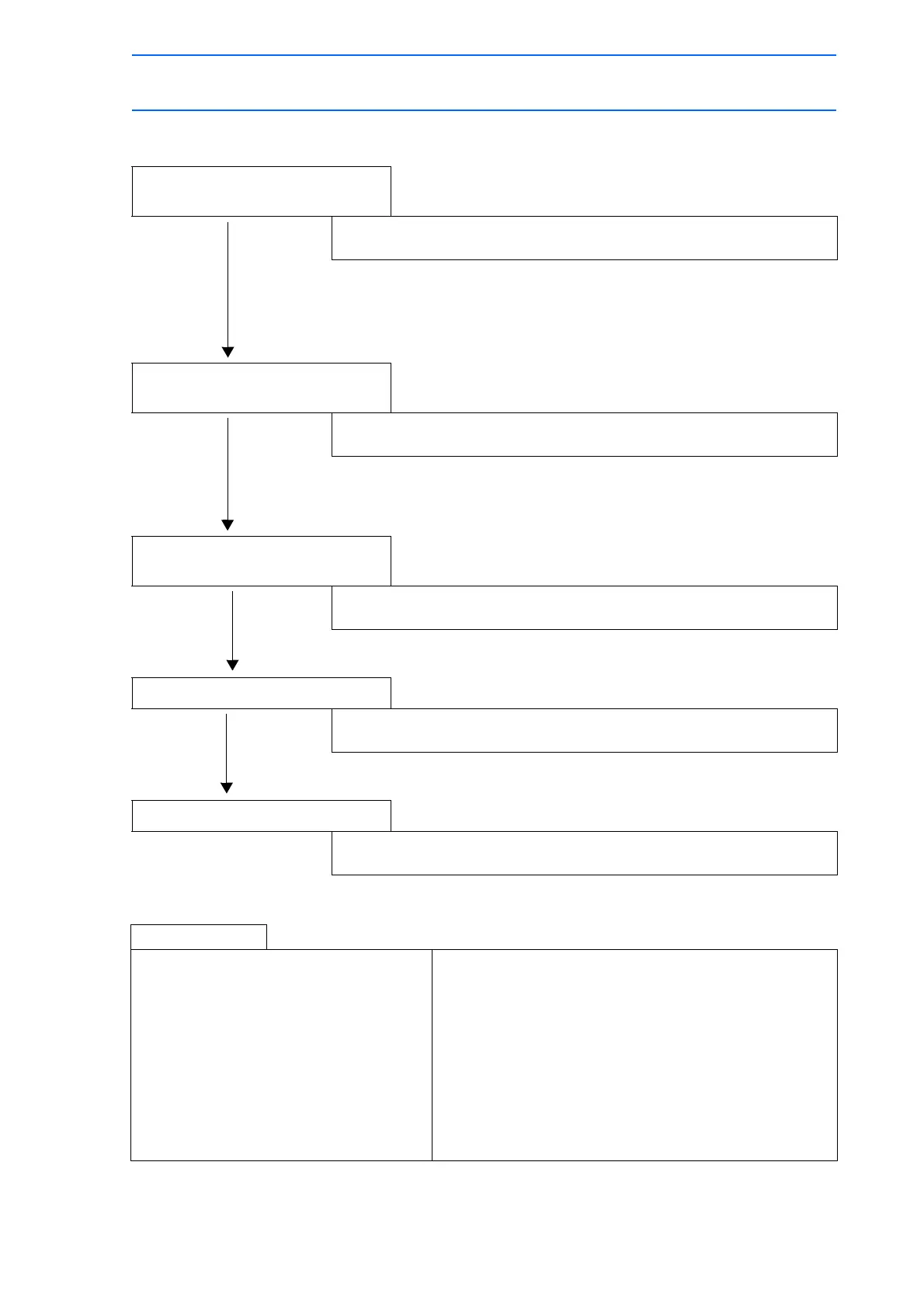

Reference Job

NOP

MOVJ VJ=10.00

MOVJ VJ=80.00

MOVL V=800

ARCON AC=200 AVP=100

MOVL V=50

ARCOF AEF#(1)

MOVL V=800

MOVJ VJ=50.00

END

Moves to the taught position (welding start point) using

linear interpolation. Speed units: cm/min.

Turns ON the arc start signal to the Power Source.

Specifies welding current: 200A, welding voltage: 100%.

Moves to the taught position (welding end point) using

linear interpolation. Speed units: cm/min.

Turns OFF the arc start signal to the Power Source.

Loading...

Loading...