6 Convenient Functions

6.2 Parallel Shift Function

6-5

149235-1CD

RE-CSO-A031

6.2.2 Setting the Shift Value

Registering Position Variables

The NX100 has 128 position variables (P000 to P127); these can be used to define parallel shift values.

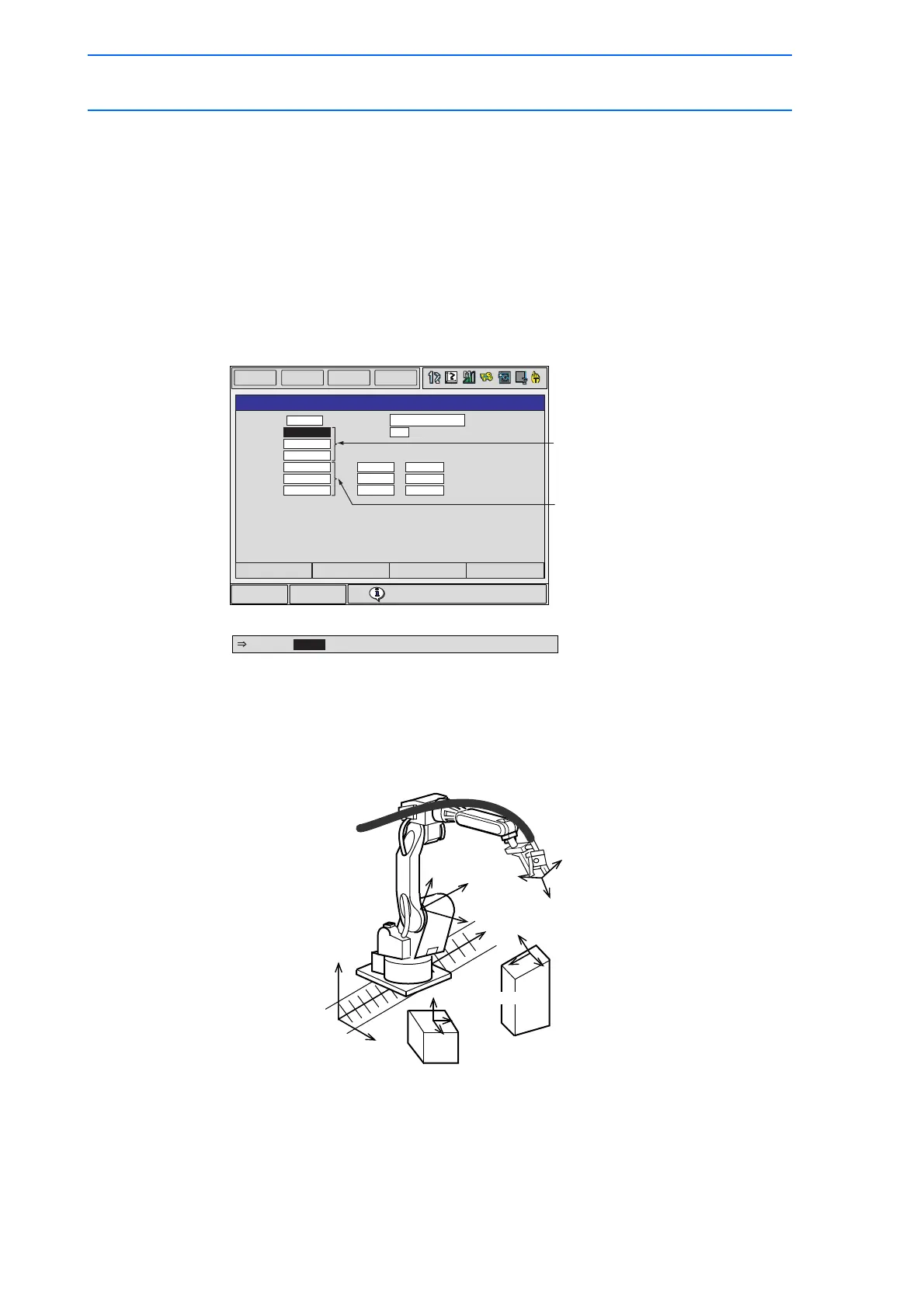

When using the parallel shift function, it is necessary to measure the distance between the teaching

point and the shift destination position (XYZ displacement of each coordinate) and then register this in

advance as a position variable.

When the shift instruction is executed in playback, the operation is performed at a location shifted from

the taught position by the amount registered for the specified position variable. The POSITION

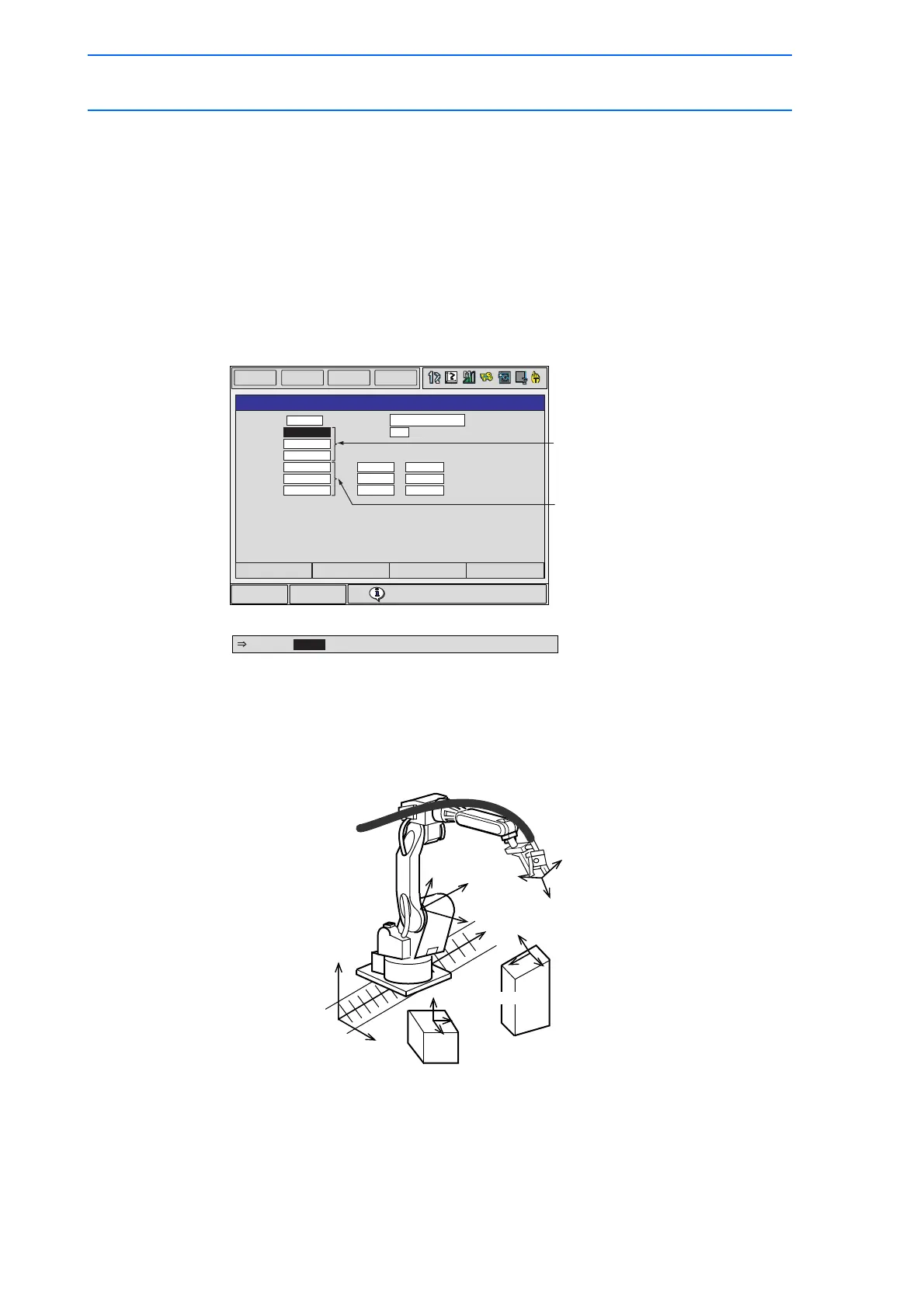

VARIABLE window is shown in the following.

Coordinate Systems

The shift value for parallel shift is X, Y, and Z increment in each coordinates. There are four

coordinates: base coordinates, robot coordinates, tool coordinates, and user coordinates. In systems

with no servo track, the base coordinates and robot coordinates are the same.

DATA

EDIT

DISPLAY

UTILITY

Main Menu ShortCut

!Turn on servo power

POSITION VARIABLE

NAME:

TOOL: 00

<TYPE>

FRONT S>=180

UP

R>=180

FLIP T< 180

#P000

R1:X

Y

Z

Rx

Ry

Rz

ROBOT

-200.000

0.000

500.000

0.00

0.00

0.00

Amount of

shift (mm)

Amount of wrist

displacement (° )

Base coordinates

Robot coordinates

Tool coordinates

User coordinates

User coordinates

Loading...

Loading...